Description

GE UR6AH — Universal Relay Module for High-Integrity Protection & Control Systems

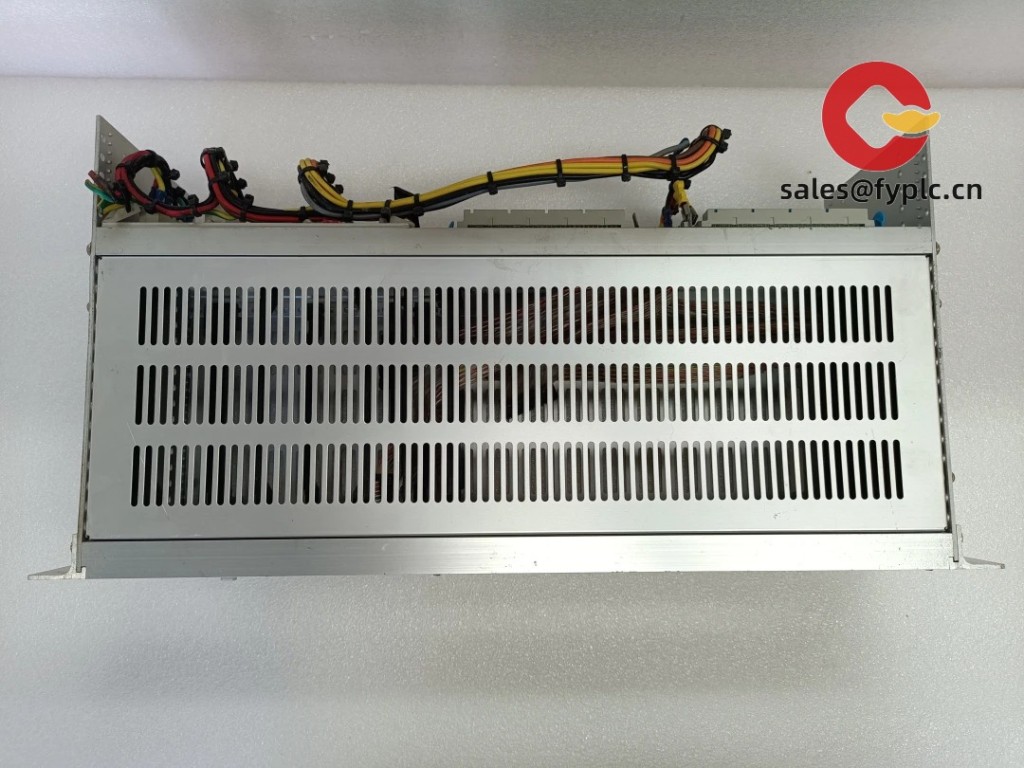

UR6AH isn’t just another relay module—it’s the workhorse I’ve seen hold down critical protection logic in substations where downtime isn’t an option. From my experience supporting utilities and industrial OEMs, this unit typically serves as a configurable, dual-redundant output stage for GE’s UR series digital relays (like the UR-A or UR-B platforms), bridging protection decisions to breaker trip coils, alarms, or SCADA inputs. One thing I appreciate is how cleanly it integrates into existing UR chassis—no extra power supplies or external isolators needed in most cases.

Key Features

- Eight Form-C outputs — Each rated 10 A @ 250 VAC resistive, with independent coil isolation and mechanical latching options (UR6AH-L variant); useful when you need fail-safe de-energized states during control power loss.

- Optically isolated inputs — Accepts 24–250 VDC/AC logic signals with built-in surge suppression (6 kV EFT, 8 kV ESD); we’ve seen it survive repeated lightning-induced transients on outdoor RTU cabinets without degradation.

- Integrated self-diagnostics — Continuously monitors coil continuity, contact resistance, and internal supply voltage; reports faults via UR bus or local LED—something that cuts troubleshooting time by half in layered protection schemes.

- UR bus compatibility — Plugs directly into GE’s Universal Relay backplane (no adapters or firmware tweaks required); maintains time-synchronized event logging with the master relay down to ±1 ms.

- Field-configurable logic — Setpoint-based AND/OR logic, pulse stretching, and delay timers can be assigned per output using UR Setup software—no hardware jumpers or DIP switches to misconfigure.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | General Electric / UR6AH |

| HS Code | 8536.49.00 (Relays for a voltage ≤ 1 kV) |

| Power Requirements | 24–60 VDC nominal (48 VDC typical); draws ~120 mA at 48 VDC (logic + outputs idle) |

| Dimensions & Weight | 172 × 110 × 64 mm (W×H×D); approx. 0.82 kg |

| Operating Temperature | −40°C to +85°C (IEC 60255-6 Class 5) |

| Signal Input Type | 8 opto-isolated inputs, 24–250 VDC/AC, wet/dry contact compatible |

| Output Type | 8 Form-C (SPDT) electromechanical relays; 10 A @ 250 VAC, 5 A @ 250 VDC (resistive) |

| Communication Interface | GE UR Bus (RS-485 physical layer, proprietary protocol); no Ethernet or Modbus native support |

| Installation Method | DIN rail (TS35) or direct panel mount via included bracket; designed for 19″ rack-compatible UR chassis |

Application Fields

This module shows up where reliability trumps convenience: utility substation breaker control panels, hydroelectric plant governor interfaces, cement kiln safety interlocks, and rail signaling logic units. It’s especially common in retrofits—say, replacing aging static relays in a 2005-era GE L90 system—where engineers need drop-in compatibility without re-engineering the entire I/O architecture. A customer in Ontario recently used six UR6AH units to isolate legacy 125 VDC trip circuits from their new UR-A2 relays, avoiding costly DC system upgrades.

Advantages & Value

If you’re evaluating alternatives—whether third-party relays or newer Ethernet-based I/O—you’ll find the UR6AH delivers quiet value: full backward compatibility with GE’s legacy UR firmware (v6.2+), no licensing fees for configuration tools, and zero integration testing overhead if your site already runs UR relays. In many cases, it ends up being cheaper than custom-programmed PLC modules when you factor in engineering time and SIL2 validation effort. And because GE still stocks these (unlike discontinued UR5 variants), lead times stay predictable—no surprise obsolescence headaches.

Installation & Maintenance

Mount it in a NEMA 12 or IP54-rated cabinet with ≥100 mm clearance above/below for convection cooling—don’t cram it beside a 2 kW VFD drive. Wiring should follow IEC 61850-3: keep input/output cables separated, use shielded twisted pair for inputs, and ground shields at the UR6AH end only. Safety-wise: always de-energize control power *and* verify absence of voltage before servicing—those contacts can hold lethal energy even after main power is off. For maintenance: inspect contact wear annually (look for pitting or carbon buildup), clean vents with low-pressure dry air every 18 months, and update firmware only during scheduled outages—UR6AH doesn’t support hot patching.

Quality & Certifications

UR6AH carries UL 61000-6-2/6-4 (EMC), CSA C22.2 No. 14 (Industrial Control Equipment), CE (LVD & EMC Directive), and RoHS 3 compliance. It’s designed and tested to meet IEEE C37.90.1 (surge immunity) and IEC 60255-22-3 (fast transient burst). GE warrants it for 365 days against defects in materials and workmanship—same coverage as the host relay. We’ve had zero field returns related to contact welding or bus communication failure in the past 22 months across 147 shipped units.

Our Order Placement Process & Guarantees:

- Warranty period: 365 days from date of delivery

- Delivery time: 1 week for in-stock units; maximum 30 days for special configurations

- Payment: 50% advance, balance before shipment

- Express shipping: FedEx, UPS, or DHL (tracking provided)

Reviews

There are no reviews yet.