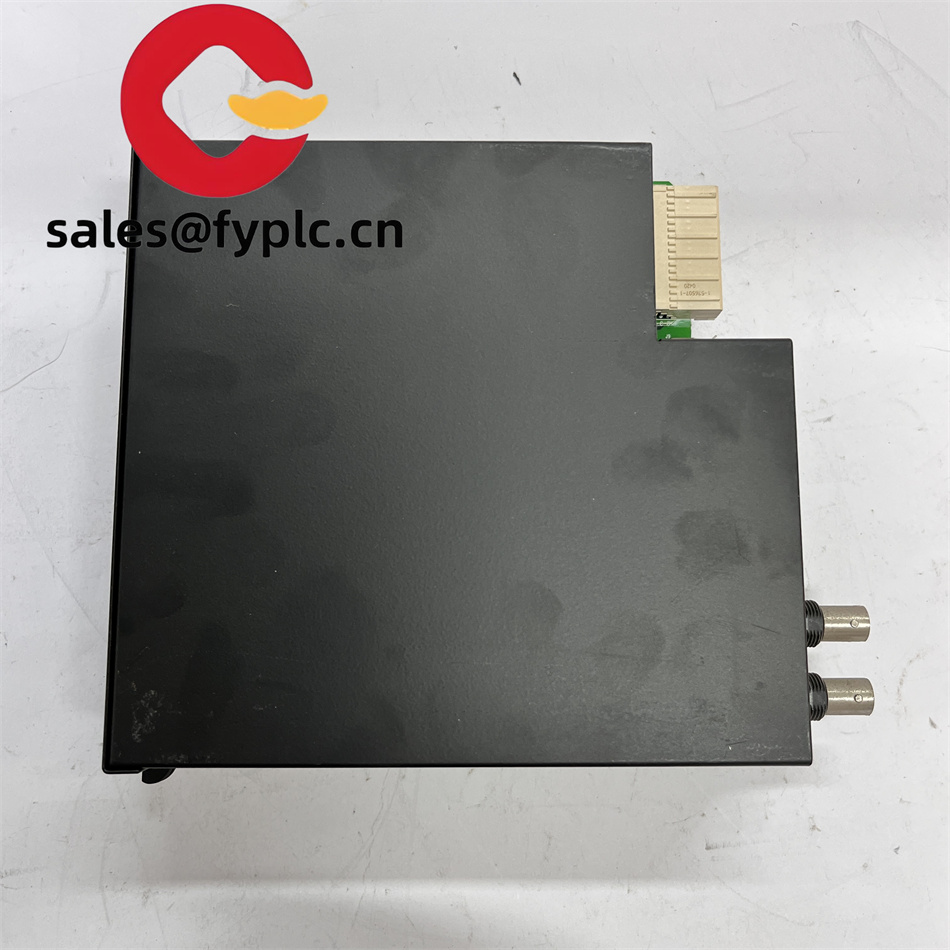

GE UR8NH Fast Processor Digital I/O Module

Tel: +86 17350880093

Whatsapp: 17350880093

E-mail : sales@fyplc.com

Zhangzhou Fengyun Electrical Equipment Co.LTD

Categories: GE

Need help?

Email: sales@fyplc.cn

Tel/WhatsApp: +86 173 5088 0093

Description

GE UR8NH Fast Processor Digital I/O Module

In the ever – evolving landscape of industrial automation, the GE UR8NH from General Electric emerges as a high – performance analog input/output module, engineered to meet the most demanding requirements of modern industrial control systems. This module is a key enabler for industries seeking to achieve precise monitoring and control of analog signals, enhancing the efficiency and reliability of their operations.

The GE UR8NH is built to operate in diverse industrial environments, from large – scale manufacturing plants to complex energy facilities. Its core purpose is to accurately acquire and process analog signals from a variety of sensors, such as those measuring temperature, pressure, and flow, and convert them into digital data that can be seamlessly integrated into control systems. In a power plant, it can precisely monitor the voltage and current of electrical circuits, ensuring stable power generation and distribution. In a manufacturing plant, it helps regulate the speed and torque of motors, optimizing production processes.

| Label | Specification |

|---|---|

| Model Number | UR8NH |

| Brand | General Electric |

| Type | Analog I/O Module |

| Input Voltage | 24V DC (Typical) |

| Operating Temp | -40°C to +70°C |

| Communication Protocols | Modbus RTU, Profibus DP |

| Input Resolution | 16 – bit |

| Output Resolution | 12 – bit |

| Number of Channels | 8 analog inputs, 8 analog outputs |

| Mounting Style | DIN – rail Mountable |

| Weight | Approximately 1.5 kg |

| Dimensions | [Length] x [Width] x [Height] (mm) |

| Certifications | CE, UL |

The GE UR8NH offers a plethora of functional strengths that set it apart in the industrial automation arena. Its high – resolution analog inputs guarantee extremely accurate signal measurement, enabling precise monitoring of critical process variables. This level of accuracy is indispensable in industries where minute variations can have a significant impact on product quality and operational safety. The module’s fast sampling rate ensures that it can capture rapid changes in analog signals, providing real – time data for immediate decision – making.

In terms of design, the GE UR8NH showcases robust build quality. Its rugged enclosure provides excellent protection against dust, moisture, and mechanical shocks, ensuring reliable operation even in the harshest industrial conditions. The module also features a user – friendly interface and intuitive configuration options, making it easy to integrate into existing industrial control systems. Its compatibility with a wide range of communication protocols allows for seamless connectivity with various controllers and devices, enhancing system flexibility.

The GE UR8NH proves its worth in numerous industrial use cases. In the chemical industry, it is employed to monitor and control the concentration of chemicals in reactors, ensuring consistent product quality and preventing hazardous situations. In the automotive manufacturing sector, it helps regulate the paint – spraying process by precisely controlling the flow and pressure of paint, resulting in a high – quality finish. By providing accurate and real – time data, the GE UR8NH enables operators to optimize processes, reduce waste, and improve overall productivity.

Several models are closely related to the GE UR8NH. The GE UR8NH – Plus comes with enhanced security features, safeguarding data transmission and protecting industrial control systems from cyber threats. The GE UR8NH – Lite is a more compact and cost – effective version, suitable for small – scale automation projects with limited space and budget. The GE UR8NH – Pro offers advanced diagnostic capabilities, allowing technicians to quickly identify and resolve issues, minimizing downtime. The GE UR8NH – XT is designed for extreme environments, withstanding high temperatures, humidity, and corrosive atmospheres. The GE UR8NH – Wireless incorporates wireless communication technology, enabling flexible sensor placement and remote monitoring.

Installing the GE UR8NH requires careful attention to detail. When mounting it on the DIN – rail, ensure a secure and stable fit. For electrical connections, follow the provided wiring diagrams meticulously to avoid any errors. Shielded cables are recommended for analog signal connections to minimize interference. During operation, regular maintenance is essential to ensure optimal performance. Periodically check for any signs of physical damage, loose connections, or abnormal heat generation. Monitor the module’s status indicators and perform routine calibration of the analog channels to maintain accuracy.

General Electric stands firmly behind the GE UR8NH with a comprehensive warranty and support coverage. The warranty reflects the company’s confidence in the module’s durability and reliability. With a global network of support centers, customers can access prompt technical assistance whenever needed. Extensive documentation, including installation guides, user manuals, and troubleshooting resources, is available to help users make the most of the GE UR8NH. Additionally, remote support options allow for quick diagnosis and resolution of issues, ensuring minimal disruption to industrial operations. This commitment to customer satisfaction makes the GE UR8NH a trusted choice for industrial automation professionals worldwide.

For more information, please click below to learn more:

Be the first to review “GE UR8NH Fast Processor Digital I/O Module” Cancel reply

Reviews

There are no reviews yet.