Description

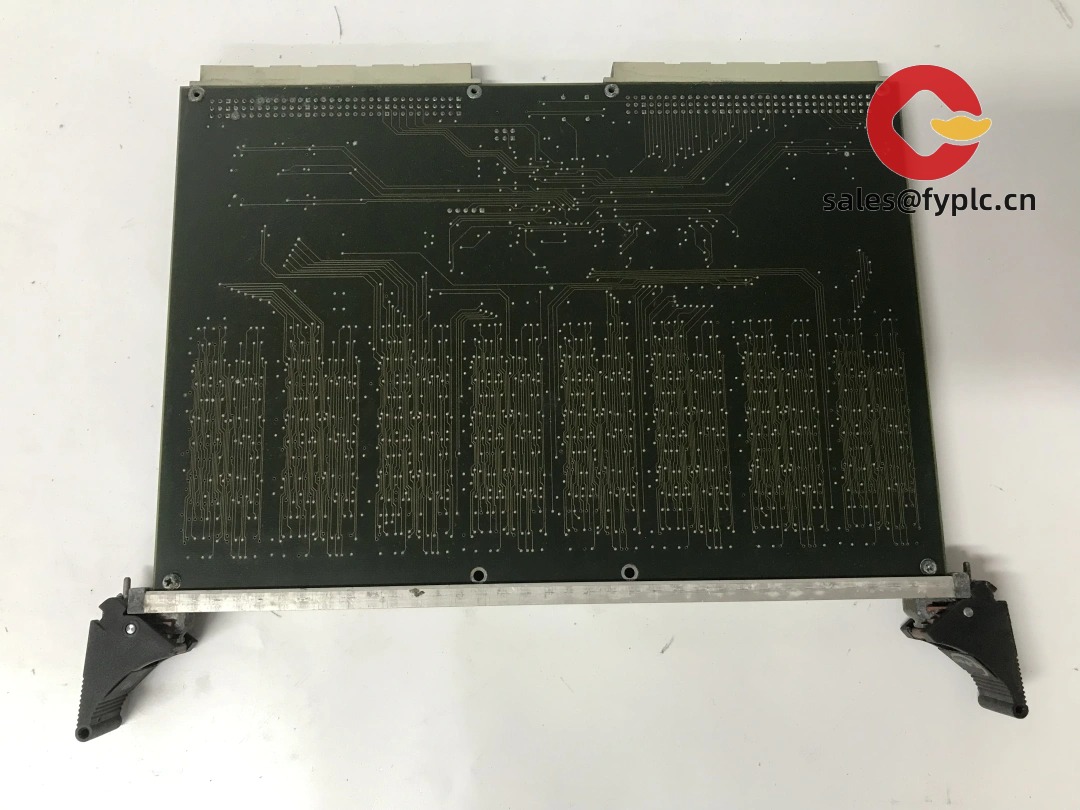

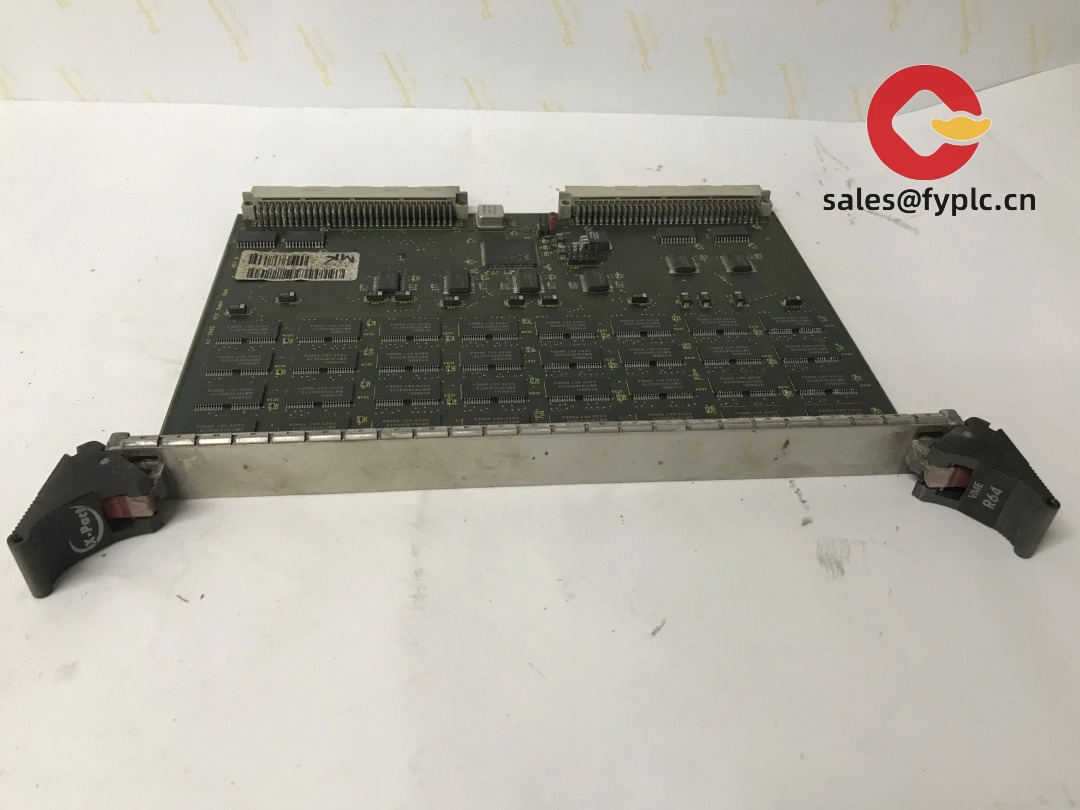

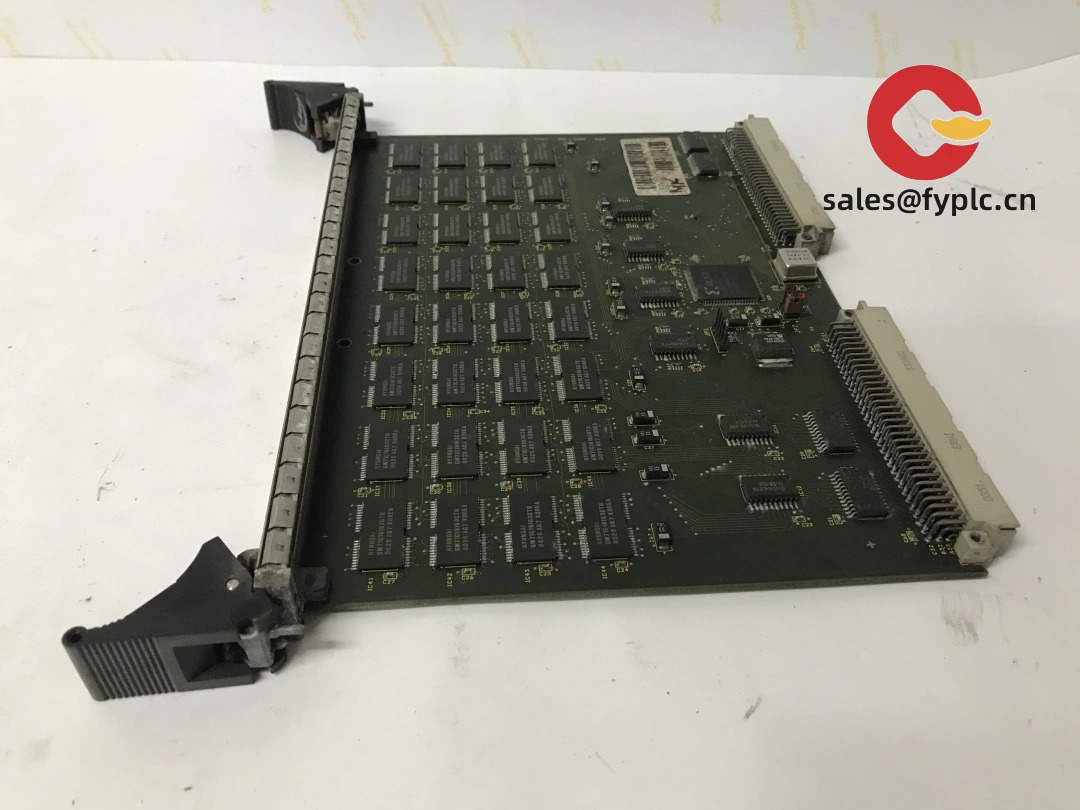

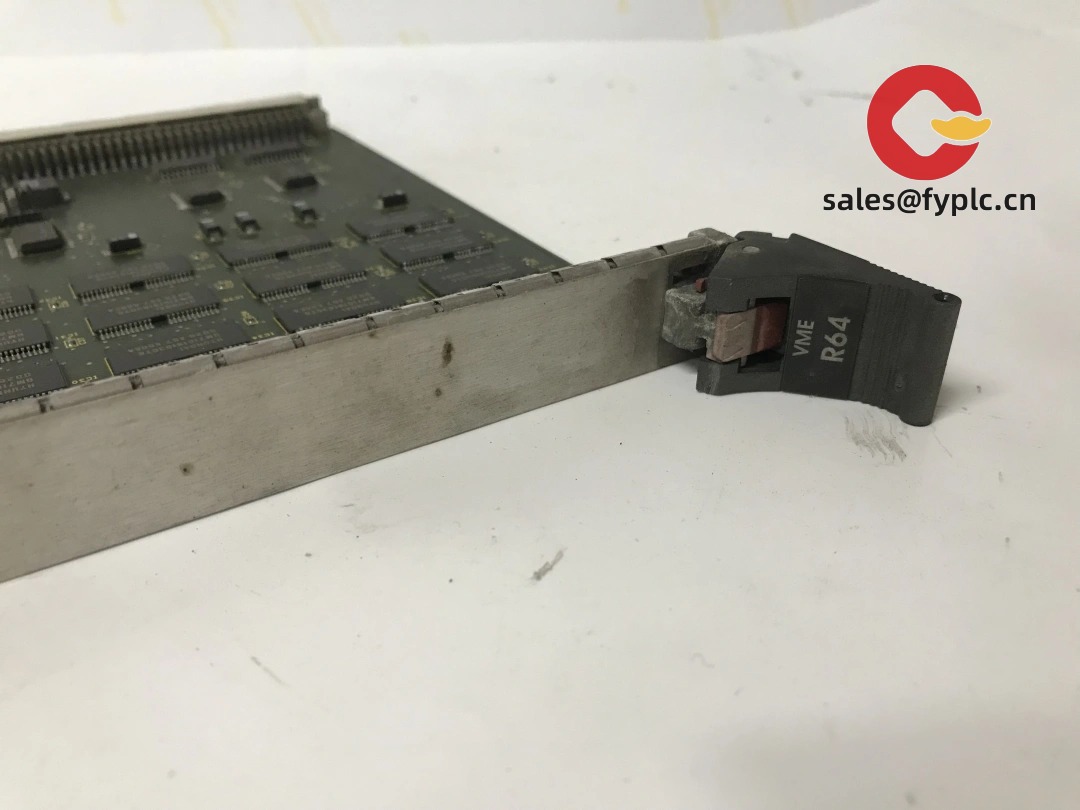

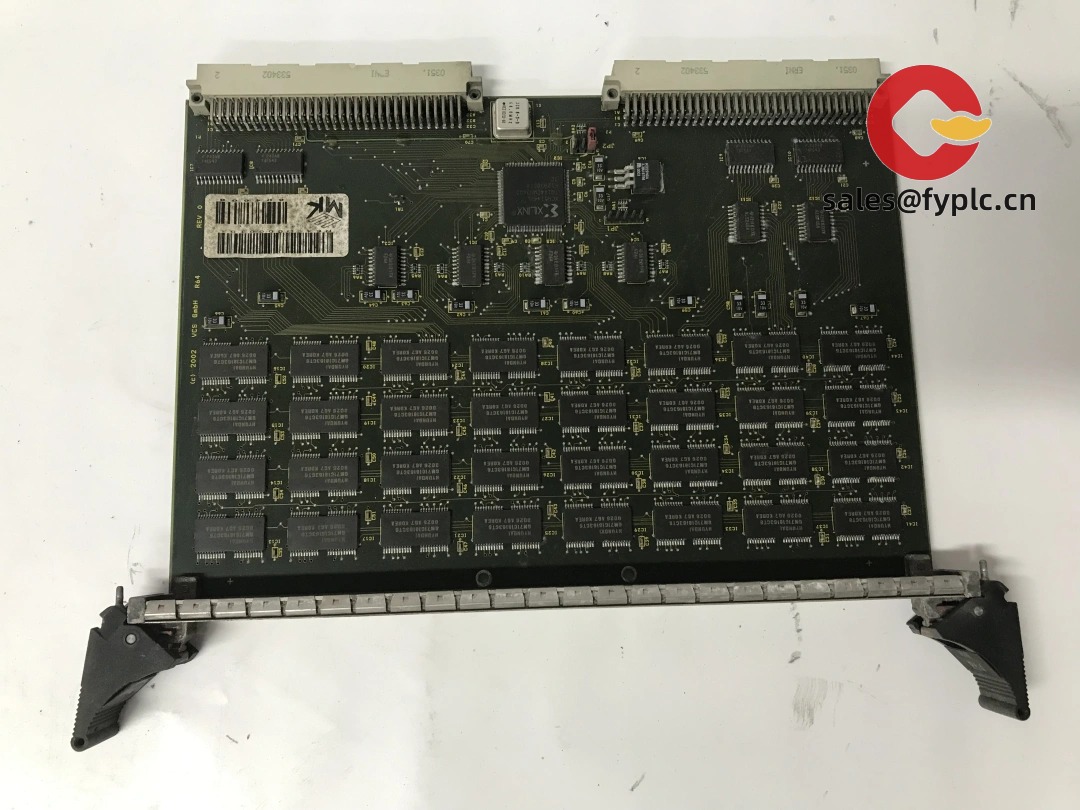

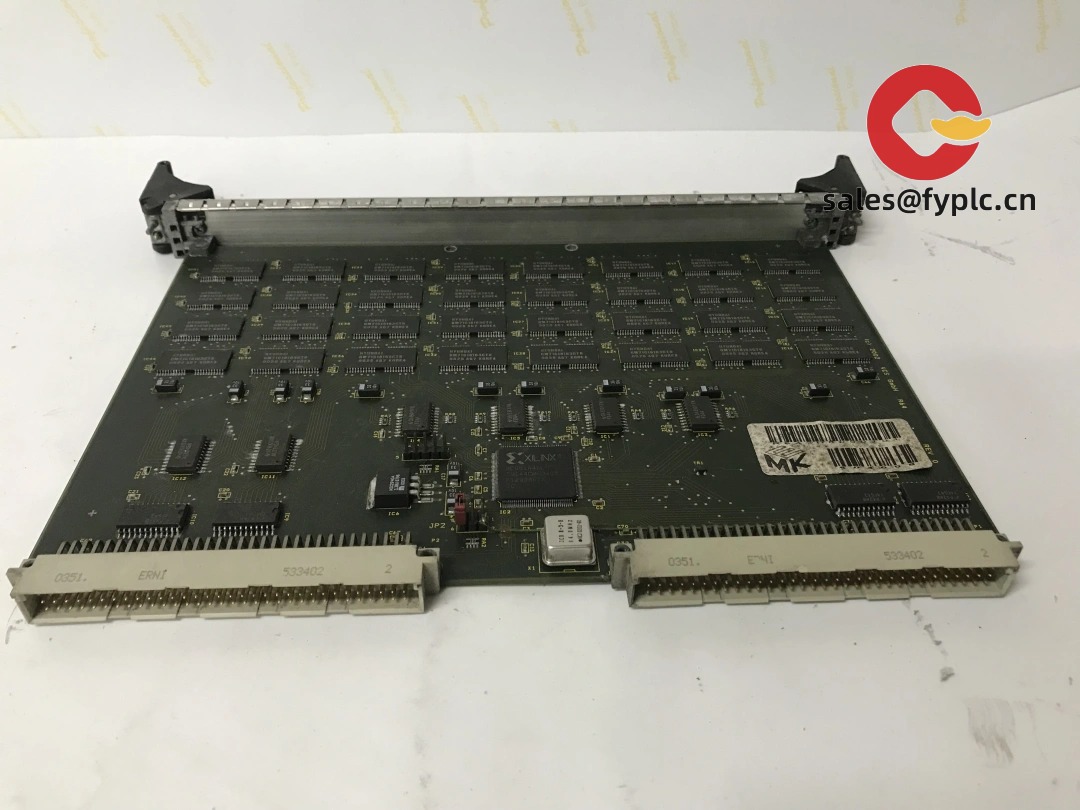

GE VMER-64 — High-Density, Modular Redundant I/O Module for Critical Control Systems

Let’s cut to the chase: the GE VMER-64 isn’t just another I/O module—it’s a field-proven workhorse designed for environments where downtime isn’t an option. From my experience supporting mid-to-large-scale distributed control systems (DCS) across power generation and water infrastructure projects, this module consistently shows up where reliability, hot-swap capability, and deterministic signal handling matter most.

You might notice that unlike many newer “smart” modules pushing Ethernet/IP or OPC UA natively, the VMER-64 leans into its VMEbus heritage—solid, predictable, and deeply integrated with legacy GE Mark VIe and Mark V control platforms. That’s not a limitation; it’s intentional engineering. One thing I appreciate is how seamlessly it slots into existing VME chassis without requiring firmware translation layers or gateway adapters.

Key Features

- 64-channel isolated digital I/O — All inputs are optically isolated (2500 VRMS), with configurable sink/source logic per channel. In practice, this means fewer external interface relays—and less panel space consumed.

- Hot-swappable with built-in redundancy support — You can replace or reconfigure modules on-the-fly while the controller remains online. Field reports from a Midwest wastewater plant confirm zero process interruption during two separate module swaps during peak flow periods.

- VME64+ compliant (ANSI/VITA 1.1) — Backward-compatible with standard VMEbus backplanes, but takes advantage of extended address/data lines for faster register access. It appears that GE tuned the arbitration logic to minimize bus contention in multi-module configurations.

- Configurable via Logic Developer–PLC or Mark VIe Toolbox — No need for proprietary hardware programmers. Configuration lives in the same environment your engineers already use for turbine protection logic—reducing training overhead.

- Onboard diagnostics & LED status per channel — Real-time visibility into open-circuit, short-circuit, and power-fail conditions. Maintenance crews at a Texas refinery told us they cut troubleshooting time by ~40% compared to older non-diagnostic modules.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | Ge VMER-64 |

| HS Code | 8537.10.90 (Control panels for industrial automation systems) |

| Power Requirements | +5 VDC @ 3.2 A typical (VMEbus slot power); no auxiliary supply needed |

| Dimensions & Weight | Single-width VME (160 × 233 mm × 15 mm); ~320 g |

| Operating Temperature | 0°C to +60°C (derated above 50°C ambient) |

| Signal Input/Output Types | 64-channel discrete I/O; 24 VDC nominal; sink or source configurable per channel; 10 ms max response time |

| Communication Interfaces | VME64+ data/address bus (A24/D16 or A32/D32); no native serial or Ethernet |

| Installation Method | Front-panel mounting into standard VME chassis; requires compatible VMEbus backplane with arbitration support |

Application Fields

This module thrives where legacy meets longevity: turbine/generator protection systems in combined-cycle plants, emergency shutdown logic in petrochemical facilities, and critical interlocks in municipal water treatment controls. It’s also found in test stands and simulation rigs—especially where deterministic scan timing and hardware-level fault detection outweigh the appeal of higher-bandwidth protocols. In many cases, users choose the VMER-64 precisely because they’re extending the life of a Mark VIe system instead of migrating to an entirely new platform.

Advantages & Value

From a procurement standpoint, the VMER-64 delivers tangible ROI—not through flashy specs, but through reduced integration risk and long-term spares predictability. Compatibility with existing GE toolchains means no retraining budgets. Spare parts availability remains strong (unlike some discontinued VME peripherals), and cross-referencing with older VMER-32 or VMER-16 modules is straightforward. Also worth noting: since it draws only from the VME bus, there’s no need for dedicated power distribution wiring—simplifying cabinet layout and reducing panel build time.

Installation & Maintenance

Install only in grounded, fan-cooled VME chassis meeting IEEE 1101.10 (VME64+) mechanical standards. Avoid placement adjacent to high-EMI modules (e.g., PWM motor drives) unless shielded. Wiring should use twisted-pair, shielded cable with drain wire grounded at the chassis end only. For safety, always de-energize the VME backplane before insertion—even though hot-swap is supported, transient surges can trip upstream fuses.

Routine maintenance is minimal: visually inspect LEDs quarterly, verify terminal torque annually (0.5 N·m max), and run diagnostic routines via Toolbox every six months. Firmware updates are rare—GE typically bundles them with broader Mark VIe controller releases—but when required, they’re applied through the host controller, not locally.

Quality & Certifications

The VMER-64 carries UL 508 (Industrial Control Equipment), CE (EMC Directive 2014/30/EU and Low Voltage Directive 2014/35/EU), and RoHS 3 compliance. It’s manufactured under ISO 9001:2015 processes at GE’s Greenville, SC facility. GE’s standard warranty applies: 365 days from date of shipment, covering defects in materials and workmanship—no exclusions for integration-related failures, provided installation follows GE’s published guidelines.

Our Order Placement Process & Guarantees:

- Warranty period: 365 days

- Delivery time: 1 week for in-stock units; no longer than 30 days for configured orders

- Payment: 50% advance, balance prior to shipment

- Express shipping: FedEx, UPS, or DHL — fully tracked and insured

Reviews

There are no reviews yet.