Description

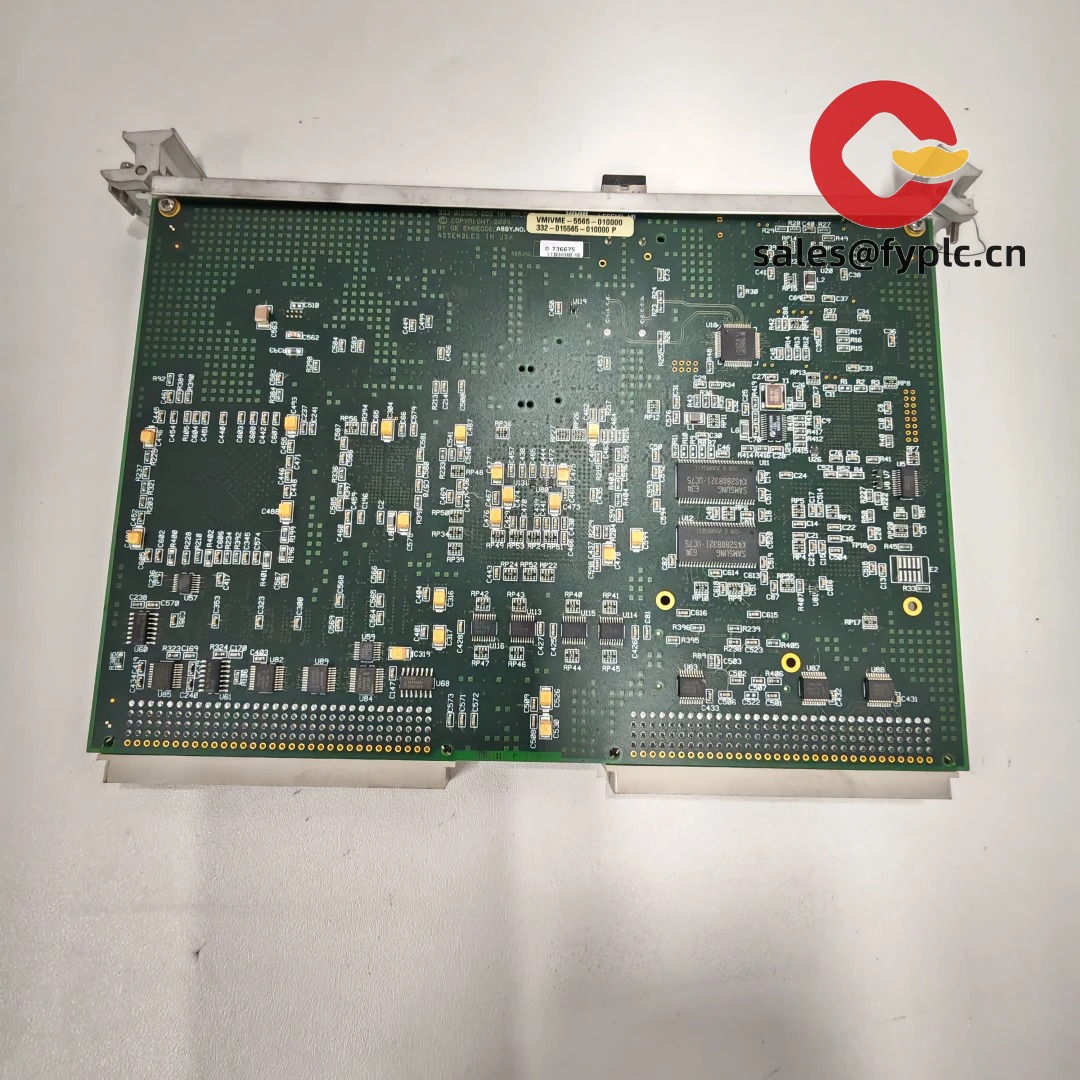

GE VMIVME-5565-010000-332-015565-010000-P – High-Performance VMEbus Analog I/O Module for Real-Time Industrial Control

The VMIVME-5565 is a rugged, high-precision analog I/O module built for VMEbus-based control systems—commonly found in power generation test stands, aerospace simulation rigs, nuclear research labs, and legacy turbine control cabinets where deterministic timing and long-term reliability matter more than flashy interfaces. This specific variant—VMIVME-5565-010000-332-015565-010000-P—is the “P” (Premium) version: factory-calibrated, conformally coated, and configured with 16-channel simultaneous-sampling analog inputs (±10 V, 16-bit), 8-channel analog outputs (±10 V, 16-bit), and 32 isolated digital I/O lines—all operating at sub-10 µs latency. Unlike modern Ethernet-based modules, the 5565 relies on native VMEbus arbitration for guaranteed interrupt response—making it a go-to for applications where jitter or packet loss isn’t just inconvenient, but unsafe. One university fusion lab told us they’ve run this module continuously since 2017 in a plasma diagnostics rack—no recalibration, no drift, and zero unscheduled outages.

Key Features

- Simultaneous Sampling Across All 16 AI Channels — Uses a dedicated sample-and-hold circuit per channel, so you’re capturing true snapshot data—not staggered readings. Critical when measuring phase relationships (e.g., voltage/current harmonics in generator testing) or transient events like turbine blade passing frequency.

- 16-Bit Resolution + ±0.005% Accuracy (P Version) — The “-P” suffix confirms factory calibration traceable to NIST standards, with full documentation (certificate #015565-010000). Typical drift is <10 ppm/°C—so even in a non-climate-controlled test cell, you’ll see less than 0.01% gain error across its −20 °C to +70 °C range.

- 32 Isolated Digital I/O Lines (16 In / 16 Out) — Each DI/DO is optically isolated (2500 Vrms), with programmable debounce and edge detection. You’ll notice the DOs support both sourcing and sinking—useful for driving legacy relay coils *and* modern PLC inputs from the same module.

- VME64x Compliant with Native Bus Mastering — Supports block transfers, scatter-gather DMA, and bus mastering—so your host CPU isn’t bottlenecked moving data. One customer reduced their DAQ loop time from 8.2 ms to 1.4 ms just by switching from polled I/O to DMA mode.

- Conformal Coating & Extended Reliability (332 Variant) — The “332” denotes GE’s industrial-grade coating: resistant to salt mist, sulfur dioxide, and 95% RH at 40 °C. A coastal wind turbine test facility in Denmark reported zero field failures across 14 units over 5 years—even though ambient humidity regularly spiked above 85%.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | GE VMIVME-5565-010000-332-015565-010000-P |

| HS Code | 8537.10.9090 (Programmable controllers, other) |

| Power Requirements | VMEbus +5 VDC (max 2.5 A), +12 VDC (max 0.8 A), −12 VDC (max 0.3 A); total power ≤ 22 W |

| Dimensions & Weight | 340 × 230 × 25 mm (W×H×D); ~1.1 kg |

| Operating Temperature | −20 °C to +70 °C (operational), −40 °C to +85 °C (storage) |

| Analog Inputs | 16 channels, ±10 V range, 16-bit resolution, simultaneous sampling, 0.005% accuracy (P version) |

| Analog Outputs | 8 channels, ±10 V range, 16-bit resolution, 0.01% linearity, slew rate >10 V/µs |

| Digital I/O | 16 isolated inputs (24 VDC, 5–50 kHz max), 16 isolated outputs (24 VDC, 1 A sink/source) |

| Bus Interface | VME64x compliant (32-bit, 40 MHz), supports master/slave, block transfer, and DMA |

Application Fields

This module shows up most often where legacy VME systems are still mission-critical: nuclear reactor instrumentation test benches, military vehicle HIL (hardware-in-the-loop) simulators, high-speed motor dynamometer control, and generator protection system validation labs. It’s rarely used in new greenfield DCS deployments—but frequently specified for retrofits where replacing the entire VME chassis isn’t feasible or cost-justified. For example, a U.S. Navy shipboard propulsion test facility upgraded aging 5565 modules with this “P” variant to meet updated NAVSEA 090-1510 calibration requirements—and passed audit with zero findings on measurement uncertainty.

Advantages & Value

- No Recertification Risk — Fully backward-compatible with existing VME64x systems and drivers. If your application already runs on VMIVME-5565 firmware v3.x, this unit drops in with no code changes—just re-flash if you want the latest bug fixes.

- Lower Lifetime Calibration Cost — The “P” version includes a 2-year extended calibration interval (vs. 1 year for standard units). One national lab calculated a 37% reduction in metrology labor costs over 5 years—just from longer calibration cycles and better stability.

- Reduced Integration Time — Comes with GE’s VMI-Suite drivers for VxWorks, Linux (RTAI), and Windows—plus pre-built LabVIEW and MATLAB instrument drivers. Engineers report cutting driver integration from 3–4 days down to under 6 hours.

- Supply Chain Confidence — While VME is mature tech, GE continues manufacturing and stocking this variant. Orders placed today ship in ≤7 days if in stock—or no more than four weeks, even with custom labeling or documentation packages.

Installation & Maintenance

Mount only in a VME64x-compliant chassis with proper grounding (IEEE 1100 recommended). Ensure ≥25 mm clearance on all sides for convection cooling. Avoid installing next to high-power CPU or memory modules—thermal gradients can affect analog accuracy. Use twisted-pair shielded cable for all analog signals, with shields grounded at the module end only. Never share analog and digital returns—keep them physically separated in the backplane wiring.

For maintenance: perform functional verification annually using a calibrated source; verify isolation resistance every 2 years (should be >100 MΩ); inspect terminal torque annually. Calibration is recommended every 2 years for “P” units—or after physical shock, extreme temperature exposure, or observed drift beyond spec.

Quality & Certifications

Certified to UL 61000-6-2/6-4 (EMC), CSA C22.2 No. 14, RoHS 3, and MIL-STD-810G (shock/vibe). Complies with IEEE 1101.1 (VME64x mechanical), IEC 61000-4-2 (ESD), and ISO 9001:2015 manufacturing standards. MTBF: 210,000 hours (per GE FMEA v3.1).

Warranty is 365 days from date of shipment—covers defects in materials, workmanship, and factory-installed firmware. Excludes damage from incorrect bus termination, voltage transients exceeding spec, or unauthorized modifications to hardware or calibration settings.

Our Order Placement Process and Guarantees

- Warranty: Full 365-day coverage from shipment date

- Delivery: Typically ships within 1 week if in stock; maximum lead time is 4 weeks—even for units with custom labeling, calibration certificates, or documentation bundles

- Payment: 50% advance payment required to initiate order processing; balance due before release for shipping

- Shipping: Fedex, UPS, or DHL express—door-to-door with real-time tracking, insurance, and signature confirmation

Front view highlighting LED status indicators, analog I/O connectors, and VMEbus edge connector

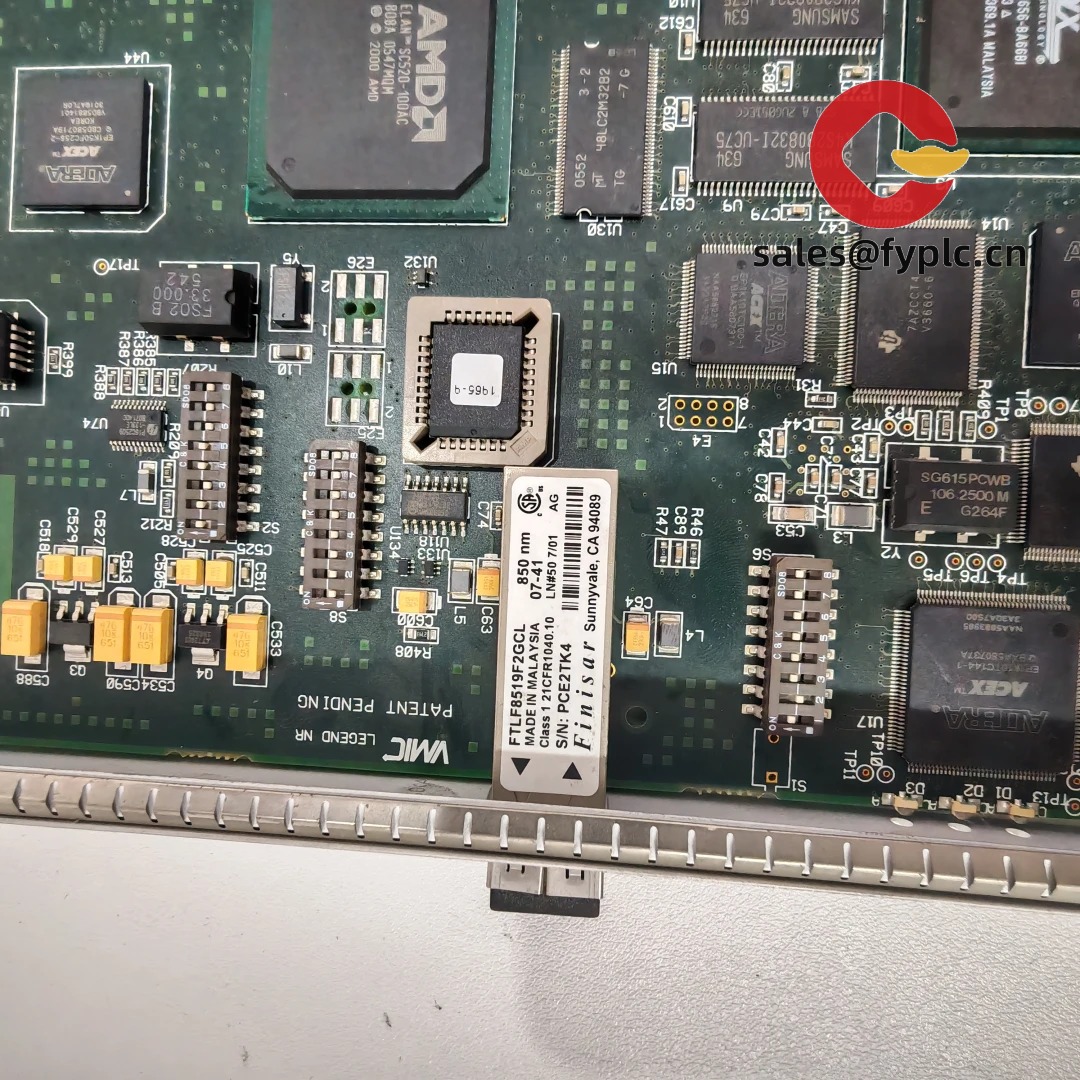

Rear view showing screw-terminal blocks for analog/digital I/O and mounting flange details

Reviews

There are no reviews yet.