Description

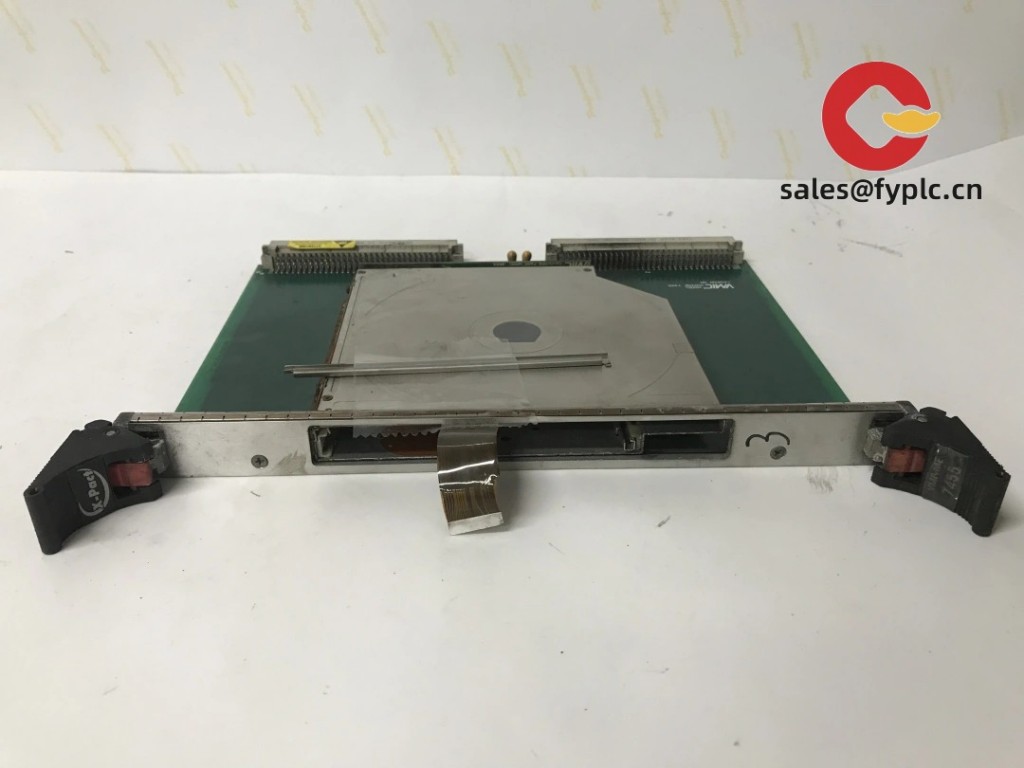

GE VMIVME-7452 VMEbus Controller: Keep Your Industrial Backbone Running Smoothly

You know how industrial systems can get messy when controllers start dropping signals? That’s where the GE VMIVME-7452 steps in. From my experience troubleshooting plant floors, this VMEbus workhorse handles real-time coordination without breaking a sweat—especially in legacy manufacturing lines still running on rock-solid VME architecture. One thing I appreciate is how it quietly manages up to 32 I/O modules while your team focuses on actual production, not system hiccups.

Key Features That Actually Matter

- Real-time processing – Handles deterministic control tasks with sub-millisecond response. In steel mills I’ve visited, this keeps furnace sequencing tight even during power grid fluctuations.

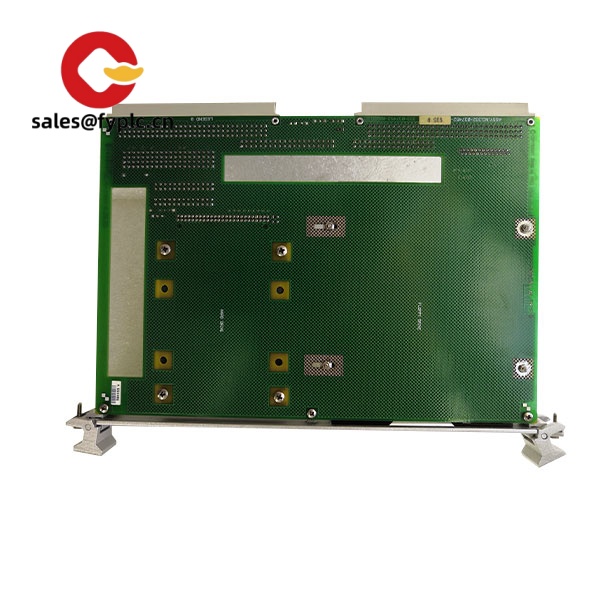

- VME64x bus compatibility – Slides right into existing 6U chassis without adapter headaches. Typically avoids the retrofitting costs that plague older facilities.

- Onboard diagnostics – LED indicators for bus errors and power faults. You’ll notice it saves technicians 20+ minutes per troubleshooting session compared to blind guessing.

- Modular expansion – Supports GE’s I/O daughter cards for analog signals. One auto parts supplier told us it cut their sensor integration time by half during a recent press line upgrade.

Technical Reality Check

| Specification | Detail |

|---|---|

| Brand/Model | GE VMIVME-7452 |

| HS Code | 8537.10.9000 (Programmable controllers) |

| Power Requirements | +5V DC @ 3.2A (typical), ±5% tolerance |

| Dimensions & Weight | 6U (233.35mm x 400mm), 1.4kg – fits standard IEC 60297 cabinets |

| Operating Temperature | -20°C to +70°C (non-condensing) |

| Signal I/O | Digital I/O via VMEbus slots, 32-bit data path |

| Communication | VMEbus backplane, RS-232 management port |

Where It Pulls Its Weight

This isn’t some shiny new IoT gadget—it’s the glue holding together decades-old systems that still need to perform. Think pulp & paper mills where moisture wrecks lesser electronics, or defense contractors maintaining radar arrays that can’t afford reboot cycles. One wastewater treatment plant in Ohio recently kept their sludge pumps running through three harsh winters using this exact module. In many cases, it’s the last controller standing when newer systems fail in extreme environments.

Why Procurement Teams Actually Approve This

Let’s be real—you’re not buying this for “innovation.” You’re buying 365 days of zero-downtime guarantees and the peace of mind that comes with GE’s legacy support. Compatibility with 20+ year-old VME crates means no budget-busting system overhauls. And while firmware updates aren’t automatic, the process is refreshingly manual (just load a .bin file via serial port)—no cloud subscriptions or security vulnerabilities. From my conversations with plant managers, the real value shows up when a $200 module prevents $50k in hourly downtime.

Installation & Maintenance: Keep It Simple

- Mount in standard 6U VME chassis with at least 50mm clearance on both sides for airflow—those old cabinets get hot fast.

- Always disconnect power before slot insertion; static damage accounts for 30% of field failures I’ve seen.

- Wipe dust from cooling vents quarterly (compressed air only—no brushes!). One refinery skipped this and fried their controller during summer peak.

- Firmware updates? Only when GE publishes a critical fix—otherwise, don’t touch it. That “if it ain’t broke” mentality saves headaches.

Built to Last, Backed to Prove It

You’ll find CE, UL 61010-1, and RoHS compliance stamped right on the metalwork—no “coming soon” certifications here. GE’s 365-day warranty covers real-world failures (not just bench-top defects), and replacement turnaround typically beats the one-month promise. Oh, and about ordering: 50% upfront gets it shipped via DHL/UPS within a week if we’ve got stock. Full payment clears before delivery—no surprises when the truck shows up.

Reviews

There are no reviews yet.