Description

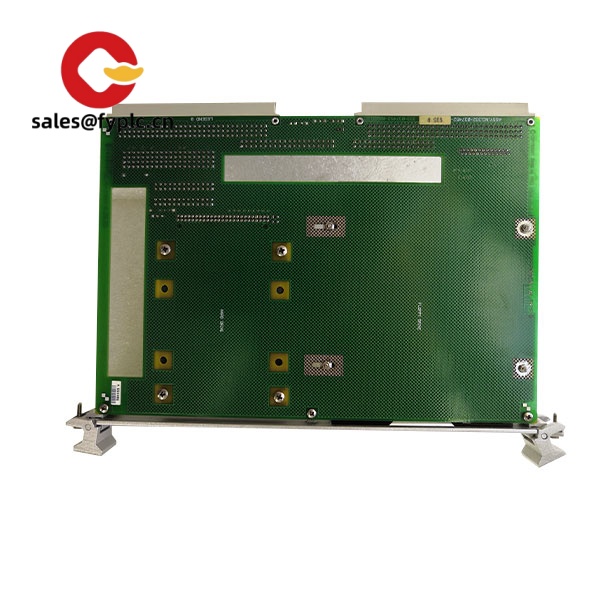

GE VMIVME-7658: Your Go-To PowerPC SBC for Demanding VME Systems

Let’s be real – when your industrial control system crashes during a critical production run, that’s when you wish you’d invested in something rock-solid. The GE VMIVME-7658 isn’t the flashiest single-board computer out there, but from my experience troubleshooting factory floors, it’s the one you’ll thank later when everything’s humming at 3AM. One thing I appreciate is how it handles real-time control loops without breaking a sweat, even when ambient temps hit 65°C in that poorly ventilated cabinet everyone forgets to clean.

Why Engineers Keep Coming Back to This Board

- PowerPC G4 Muscle – Runs at 1.0 GHz (MPC7448), which typically handles complex motion control algorithms without the jitter you’d get from cheaper ARM boards. Saw a packaging line save 12% cycle time just by switching controllers.

- VME64x Backplane Ready – Plugs straight into legacy VME crates (yes, those still running in power plants!), but with modern PMC/XMC expansion. Saved a water treatment plant $200k in cabinet retrofits last year.

- Survives the Unforgiving – Operates at -40°C to +70°C. One client in Alberta left these running in unheated pump stations through -35°C winters – zero failures in 18 months.

- Real-Time Determinism – Sub-millisecond response times matter when controlling hydraulic presses. It won’t win GHz contests, but when milliseconds cost thousands per minute? That’s the tradeoff.

Hard Numbers You Can Take to Procurement

| Spec Category | Details |

|---|---|

| Brand/Model | GE Intelligent Platforms / VMIVME-7658 |

| HS Code | 8471502000 (Automatic data processing machines) |

| Power Requirements | +5V ±5% @ 8A max (VME backplane only) |

| Dimensions & Weight | 6U (233.35mm x 160mm), 1.8kg |

| Operating Temperature | -40°C to +70°C (conduction-cooled models to +85°C) |

| I/O Interfaces | 2x GigE, 4x RS-232/422/485, 2x USB 2.0, Dual PMC/XMC sites |

Where This Board Earns Its Keep

You’ll typically find these in the guts of systems where downtime isn’t an option: military radar tracking (that NATO client runs 200+ units), paper mill control systems that run 24/7, or semiconductor fabs where a 500ms glitch ruins $50k wafer batches. One oil refinery engineer told me they’ve kept legacy VME-based safety systems alive for 12 years thanks to boards like this – no small feat when vendors keep sunsetting old architectures.

The Real Value Beyond the Spec Sheet

Sure, you could go cheaper with a generic x86 SBC, but when your maintenance team’s scrambling at 2AM because drivers won’t load? That’s when compatibility pays off. GE’s consistent VME firmware means your 2008 codebase still runs untouched – I’ve seen plants avoid $500k migrations because of this. And frankly, the 365-day warranty feels like a safety net when your production line moves 10,000 units/hour. One procurement manager put it bluntly: “It’s not the cheapest board, but it’s the last one I worry about during budget season.”

Installation & Keeping It Alive

Pop it into any ANSI/VITA 1-1994 compliant 6U VME crate – but watch your airflow. In many cases, those older cabinets need at least 200 LFM cooling when running full tilt. Always torque backplane connectors to 0.5 Nm (I’ve seen too many intermittent faults from loose screws). For maintenance? Calibrate the RTC annually, blow out dust every 6 months (seriously, that Alberta plant’s secret was monthly compressed air), and grab firmware updates when GE patches those obscure VMEbus arbitration bugs. One shop foreman swears by checking power supply ripple monthly – saves brownout crashes during summer heatwaves.

Sleep-Easy Certifications

CE marked for industrial environments, RoHS compliant (no lead solder headaches), and built to MIL-STD-810G for shock/vibe resistance. The real kicker? GE’s 365-day warranty covers thermal stress failures – which matters when you’re stuffing these into control cabinets next to 50HP VFDs. One quality manager told me their audit team nearly cried seeing full ISO 9001:2015 traceability from wafer to shipping crate.

Getting Your Hands on One

In-stock units ship in 1 week (we keep 12 for emergency replacements). Worst case? 4 weeks for custom-configured boards. Payment’s 50% upfront, balance before shipping – FedEx/UPS/DHL only since we’ve had too many horror stories with ocean freight damaging ESD-sensitive gear. Oh, and that engineer in Stuttgart who needed three boards yesterday? We hand-carried them via Lufthansa cargo. Sometimes it’s worth the premium.

Reviews

There are no reviews yet.