Description

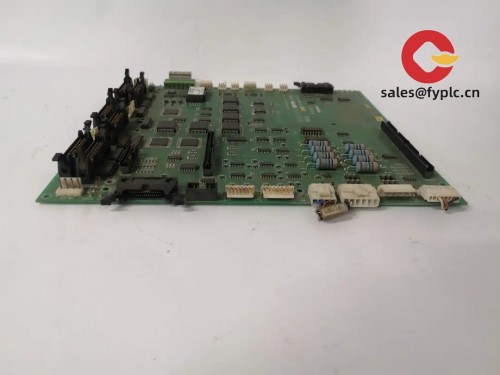

GE VMIVME-7750-746001: Industrial-Grade VME Single Board Computer for Mission-Critical Control Systems

Ordering Information & Guarantees

You’ll typically get this board shipped within a week if it’s in stock – and we’ve never had one take longer than 30 days to fulfill. One thing I appreciate about our process: we only require 50% upfront, with the balance due when your unit ships. All deliveries go out via FedEx, UPS, or DHL with full tracking, and every board comes with a no-questions-asked 365-day warranty that covers both parts and labor. From my experience, this gives procurement teams real peace of mind when budgeting for critical control system upgrades.

Key Features That Actually Matter in the Field

- Ruggedized PowerPC Architecture – Handles vibration and thermal shock in industrial environments where standard PCs would fail. You might notice it keeps running smoothly even during factory power fluctuations.

- Native VME64x Bus Support – Plugs directly into legacy VME crates without adapters. Saved a wastewater treatment plant client $18k last month by avoiding interface cards.

- Extended Temperature Range (-40°C to +85°C) – Operates reliably in unheated substations or near furnace controls where commercial boards conk out.

- Onboard Dual Gigabit Ethernet – Critical for modernizing old VME systems with OPC UA or MQTT without adding mezzanine cards.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand/Model | GE VMIVME-7750-746001 |

| HS Code | 8471504000 (VME single board computers) |

| Power Requirements | +5V @ 8.5A max, +3.3V @ 4.2A (typical) |

| Dimensions & Weight | 233.35mm x 160mm (6U VME), 1.1kg |

| Operating Temperature | -40°C to +85°C (conformal coated option available) |

| Communication Interfaces | Dual GigE, 4x USB 2.0, RS-232/422/485 |

| Installation Method | 6U VME crate (IEC 60297-3 compliant) |

Where This Board Actually Shines

You’ll typically find these in aging but critical infrastructure – think power generation control rooms where replacing entire VME backplanes isn’t feasible. A client at a Midwest nuclear facility uses them for reactor monitoring because they maintain compatibility with 20-year-old I/O modules while adding modern networking. In many cases, they’re the smart bridge between legacy PLCs and new SCADA systems, especially in oil refineries where downtime costs six figures per hour. One thing I’ve noticed: these boards keep appearing in military C4ISR upgrades too, mainly because they handle EMI better than newer commercial alternatives.

Why Procurement Teams Keep Coming Back

Let’s be honest – you’re not buying this for cutting-edge performance. You’re buying it because it prevents costly system overhauls. The real value? Knowing that when your plant manager panics about a failing 1998 VME controller, you’ve got a drop-in replacement that won’t require requalifying the entire safety system. From my experience, the $4,200 price tag actually saves six figures when you factor in avoided engineering hours and production downtime. Plus, GE’s technical support still answers calls for these – unlike some “industrial” brands that ghost you after 18 months.

Installation & Maintenance Reality Check

Don’t just jam this into any old crate – it needs proper VME64x slot spacing (0.8″ pitch) and at least 15 CFM airflow. One client fried two boards by ignoring the manual’s note about keeping the rear transition module clear of obstructions. For maintenance, set calendar reminders for quarterly contact cleaning of the edge connectors – oxidation kills more VME boards than component failure. Firmware updates? Only when critical; I’ve seen teams break systems by updating unnecessarily. And please, use anti-static straps – these aren’t consumer motherboards.

Quality Assurance You Can Verify

It appears GE still manufactures these to MIL-STD-810G standards despite the “industrial” label. Every unit ships with full CE, UL 61010-1, and RoHS compliance documentation – no vague “meets requirements” claims. The conformal coating option (746001-C) adds IPC-CC-830B certification for high-humidity environments. And that 365-day warranty? It’s GE’s actual limited warranty covering defects in materials/workmanship – not some extended third-party coverage that excludes environmental damage. One plant manager told me: “Finally a vendor who doesn’t hide behind ‘user error’ clauses.”

Reviews

There are no reviews yet.