Description

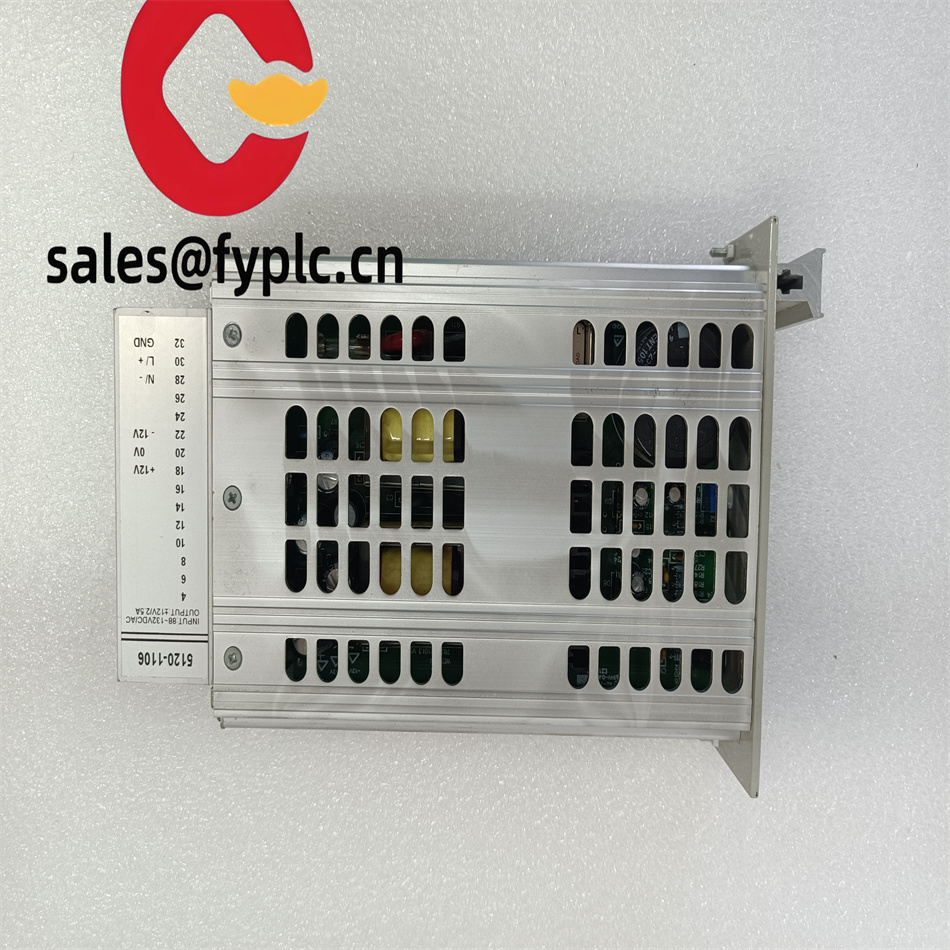

GE WES5120 5120-1106 Total Expansion Terminal Module

In the realm of industrial automation, the GE WES5120 5120-1106 stands as a robust Ethernet I/O Module designed to bridge operational technology (OT) and information technology (IT) in demanding industrial environments. Engineered for seamless integration into GE’s Proficy™ and iFIX™ automation ecosystems, this module serves as a critical link in distributed control systems (DCS), programmable logic controllers (PLCs), and supervisory control and data acquisition (SCADA) networks. Its core purpose? To enable real-time data exchange, enhance system scalability, and deliver reliable performance in harsh industrial settings, from manufacturing floors to energy production facilities.

The GE WES5120 5120-1106 is built to address the growing need for industrial systems that prioritize both speed and resilience. As a high-speed communication handler, it facilitates bidirectional data transfer between field devices, controllers, and enterprise-level software, ensuring operators can monitor, analyze, and optimize processes in real time. Whether deployed in food and beverage production lines, chemical plants, or water treatment systems, this module excels at translating raw sensor data into actionable insights—all while maintaining compatibility with legacy and modern control architectures.

By combining rugged hardware with advanced networking protocols, the GE WES5120 5120-1106 empowers industries to future-proof their automation infrastructure. Its design prioritizes ease of integration, making it an ideal choice for retrofitting existing systems or deploying in greenfield projects. For technical buyers seeking a reliable, high-performance I/O solution that aligns with Industry 4.0 standards, this module delivers unmatched value in efficiency, connectivity, and operational uptime.

| Label |

Specification |

| Model Number |

WES5120 5120-1106 |

| Brand |

GE (General Electric) |

| Type |

Ethernet I/O Module |

| Input Voltage |

24 V DC (±10%) |

| Operating Temperature |

-40°C to +70°C (-40°F to +158°F) |

| Communication Method |

10/100 Mbps Ethernet, TCP/IP |

| Mounting |

DIN-rail or panel-mount |

| Weight |

0.5 kg (1.1 lbs) |

| Certifications |

CE, UL, cUL, ATEX (Zone 2/22) |

| Dimensions (W×H×D) |

100 mm × 150 mm × 50 mm (3.94″×5.91″×1.97″) |

| IP Rating |

IP20 (indoor use) |

| Protocols Supported |

Modbus TCP, EtherNet/IP, GE Genius Bus |

The GE WES5120 5120-1106 distinguishes itself through its industrial-grade resilience and versatile connectivity. Engineered with a rugged metal enclosure, it withstands shock, vibration, and electromagnetic interference (EMI), making it suitable for harsh environments where reliability is non-negotiable. Its wide operating temperature range ensures consistent performance in both extreme cold and high-heat zones, such as near furnaces or in outdoor substations.

A key design advantage lies in its dual Ethernet ports, which support linear or ring topology networks for enhanced redundancy—a critical feature in systems where downtime is costly. This module also simplifies inventory management by offering hot-swappable functionality, allowing maintenance without disrupting ongoing operations. For engineers, its plug-and-play compatibility with GE’s Proficy Machine Edition software reduces programming time, while built-in diagnostics (LED indicators for power, network, and I/O status) enable rapid troubleshooting.

Interoperability is another cornerstone of the WES5120 5120-1106. By supporting multiple industrial protocols (Modbus TCP, EtherNet/IP), it acts as a universal translator between disparate devices, from legacy sensors to modern IIoT gateways. This flexibility future-proofs systems, ensuring they can adapt to evolving automation standards without requiring a complete overhaul.

In manufacturing, the GE WES5120 5120-1106 excels in smart factory applications. For example, in a pharmaceutical packaging line, it connects robotic pick-and-place arms, vision inspection systems, and MES (manufacturing execution systems) via EtherNet/IP, enabling real-time quality control data to flow directly to plant managers. This reduces waste by 15–20% by flagging defective products early in the process and optimizing machine coordination.

In energy and utilities, the module serves as a vital component in distributed generation systems. At a solar farm, it aggregates data from hundreds of inverters and weather stations via Modbus TCP, transmitting this information to a SCADA system for predictive maintenance. The result? Improved uptime for solar arrays and a 10% increase in energy yield through proactive fault detection. For water treatment plants, its rugged design ensures reliable operation in wet, corrosive environments, where it monitors pump statuses and chemical dosing systems, ensuring compliance with regulatory standards while minimizing operational costs.

By delivering high-speed data integration, robust reliability, and protocol flexibility, the GE WES5120 5120-1106 empowers industries to build smarter, more connected automation systems—where every sensor, controller, and software layer works in unison to drive efficiency, safety, and innovation.

For more information, please click below to learn more:

Reviews

There are no reviews yet.