GE WES5123-2600 Field Controller Unit

Tel: +86 17350880093

Whatsapp: 17350880093

E-mail : sales@fyplc.com

Zhangzhou Fengyun Electrical Equipment Co.LTD

Categories: GE

Need help?

Email: sales@fyplc.cn

Tel/WhatsApp: +86 173 5088 0093

Description

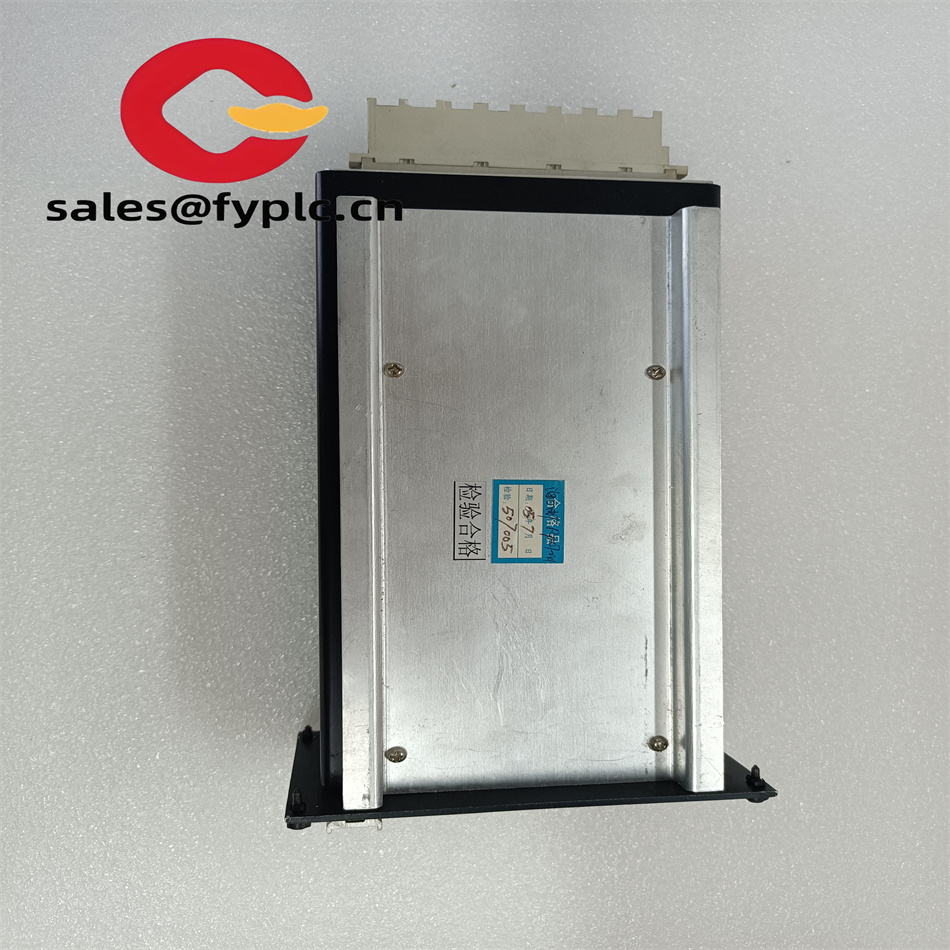

GE WES5123-2600 Field Controller Unit

Introduction & Core Purpose

In the demanding landscape of industrial automation, the GE WES5123-2600 stands as a cutting-edge Ethernet/IP Safety I/O Module, meticulously engineered to deliver uncompromising reliability, real-time data accuracy, and advanced safety compliance in mission-critical environments. As a flagship component of GE’s Proficy™ safety automation suite, this module is designed to integrate operational technology (OT) with IT systems while adhering to the most rigorous functional safety standards. Its primary mission? To enable seamless, secure communication in safety-integrated control systems (SIS), smart manufacturing lines, and hazardous industrial settings where even 微小的中断 could lead to severe consequences.

The GE WES5123-2600 is purpose-built for industries where safety and performance are non-negotiable, such as oil refineries, chemical plants, and automotive manufacturing with high-risk operations. Unlike conventional I/O modules, this unit combines high-speed EtherNet/IP connectivity with SIL 3 certification (IEC 61508) and PL e compliance (ISO 13849-1), making it ideal for applications requiring fail-safe data transmission—from emergency shutdown systems to robotic safety interlocks. For instance, in a chemical processing facility, it can monitor volatile organic compound (VOC) sensors and transmit critical data to safety PLCs via EtherNet/IP, ensuring instantaneous activation of protective measures in the event of a leak.

By merging rugged hardware with advanced safety and cybersecurity features, the GE WES5123-2600 future-proofs automation systems against evolving industry regulations and cyber threats. Its dual-port Ethernet architecture supports ring topology for network redundancy, while built-in security protocols (e.g., AES-128 encryption, secure boot) safeguard against unauthorized access. Technical buyers seeking a unified solution for operational efficiency, safety compliance, and digital transformation will find this module indispensable for building resilient, ISO 13849-1 and IEC 61508-certified ecosystems.

2. Technical Highlights Table

| Label | Specification |

|---|---|

| Model Number | WES5123-2600 |

| Brand | GE (General Electric) |

| Type | Ethernet/IP Safety I/O Module |

| Input Voltage | 24 V DC (10–30 V DC wide-range) |

| Operating Temperature | -40°C to +70°C (-40°F to +158°F) |

| Communication Method | 10/100/1000 Mbps Ethernet, EtherNet/IP |

| Mounting | DIN-rail (TS35/7.5 or TS35/15) |

| Weight | 0.7 kg (1.54 lbs) |

| Certifications | CE, UL, cUL, ATEX (Zone 1/21), SIL 3 (IEC 61508), ISO 13849-1 (PL e) |

| Dimensions (W×H×D) | 130 mm × 190 mm × 70 mm (5.12″×7.48″×2.76″) |

| IP Rating | IP20 (indoor, controlled environment) |

| Protocols Supported | EtherNet/IP, Modbus TCP, CIP Safety |

| Safety Features | Dual-channel redundancy, 99%+ diagnostic coverage, fail-safe relay outputs |

| Cybersecurity | Encrypted data transmission (AES-128), secure boot, anti-tamper firmware |

3. Functional Strengths & Design Advantages

The GE WES5123-2600 excels in safety-critical applications through its SIL 3-certified dual-channel architecture. This design provides hardware redundancy, ensuring that if one channel fails, the other maintains uninterrupted operation—critical for systems classified as Category 4 (ISO 13849-1). The module’s advanced diagnostics continuously monitor power, communication, and I/O channels with over 99% coverage, while fail-safe relay outputs automatically trigger safe states (e.g., emergency stops) during critical faults, minimizing risk to personnel and assets.

Industrial-grade durability is inherent to its design: a rugged steel enclosure withstands shocks up to 50 g, vibration (3 g rms), and electromagnetic interference (EMI), while conformal-coated PCBs protect against dust, moisture, and corrosive gases in harsh environments like metal foundries or wastewater treatment plants. The WES5123-2600 also supports hot-swapping, allowing maintenance without disrupting safety-critical processes—a feature that reduces mean time to repair (MTTR) by up to 50% compared to non-redundant systems.

For engineers, native support for CIP Safety over EtherNet/IP simplifies integration into mixed-vendor safety networks, while plug-and-play compatibility with GE’s Proficy Safety Manager software streamlines configuration. Built-in cybersecurity features, including secure boot and encrypted data transmission, address growing OT network vulnerabilities, making it suitable for industries under threat of cyber-physical attacks, such as energy and critical infrastructure.

4. Industrial Use Cases & Value Scenarios

In oil and gas upstream operations, the GE WES5123-2600 ensures the integrity of safety instrumented systems (SIS) in offshore platforms. It connects pressure transmitters, flame detectors, and emergency shutdown valves via CIP Safety, enabling real-time monitoring of wellhead operations. In the event of a pipeline leak, the module’s fail-safe outputs trigger shutdowns within milliseconds, preventing environmental disasters and ensuring compliance with IEC 61511 standards. Its redundant Ethernet ring topology also eliminates single points of failure, reducing unplanned downtime by 30% during routine maintenance.

In automotive stamping plants, where high-tonnage presses and human workers coexist, the module enhances safety and productivity. It interfaces with safety mats, light curtains, and robot controllers via EtherNet/IP, creating a unified safety network that detects unauthorized access to press cells. The result? A 25% improvement in safety incident response times and seamless integration with Proficy SCADA for real-time visualization of safety events and production metrics. This dual functionality reduces the need for separate safety and operational networks, lowering infrastructure costs by 20%.

For pharmaceutical filling lines, the WES5123-2600 ensures compliance with cGMP and FDA regulations by providing tamper-proof data logging and secure communication between sterile processing equipment and quality control systems. Its ability to operate in ISO Class 5 cleanrooms while maintaining SIL 3 certification makes it essential for automated drug dispensing systems, where precision and safety are non-negotiable. By minimizing manual interventions and enhancing traceability, the module reduces the risk of contamination and product recalls, safeguarding both patient safety and brand reputation.

For more information, please click below to learn more:

Be the first to review “GE WES5123-2600 Field Controller Unit” Cancel reply

Reviews

There are no reviews yet.