Description

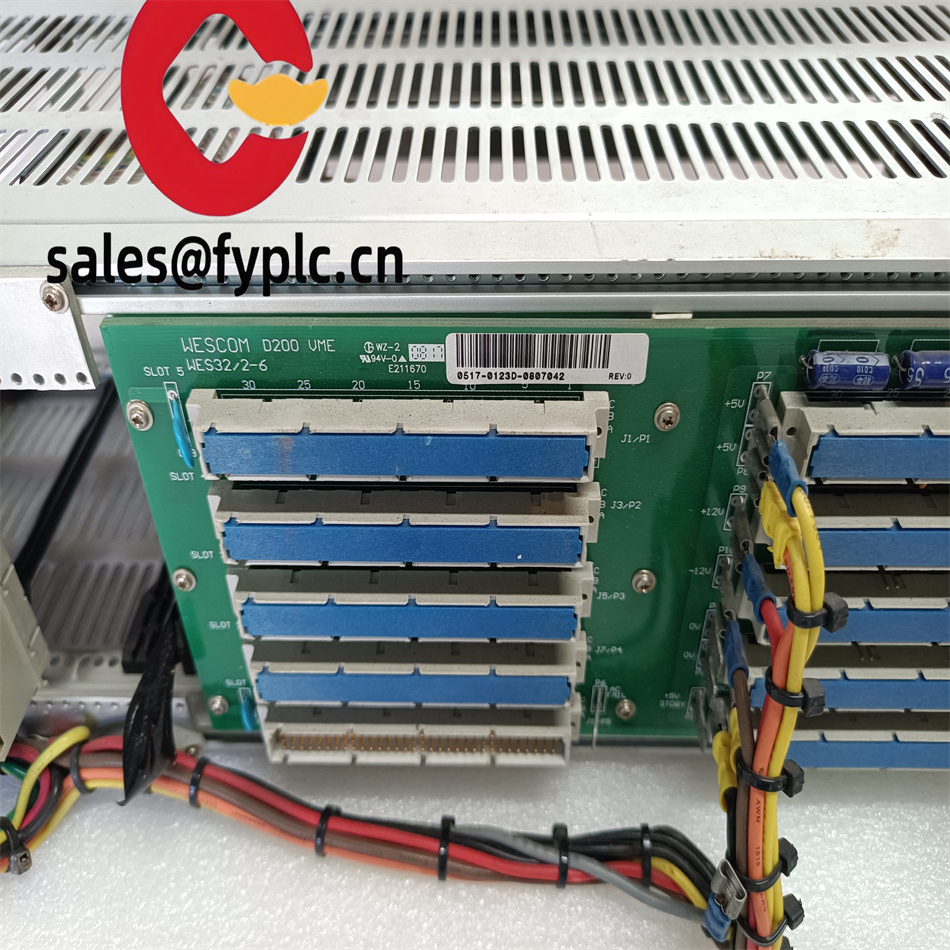

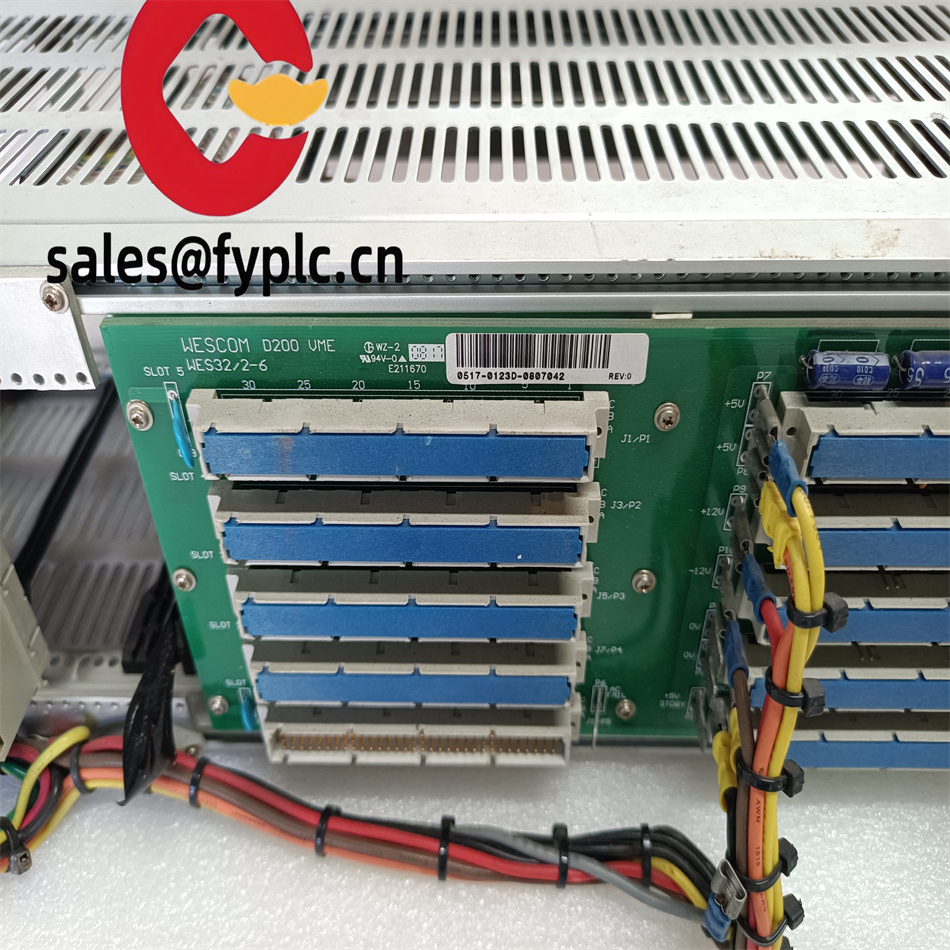

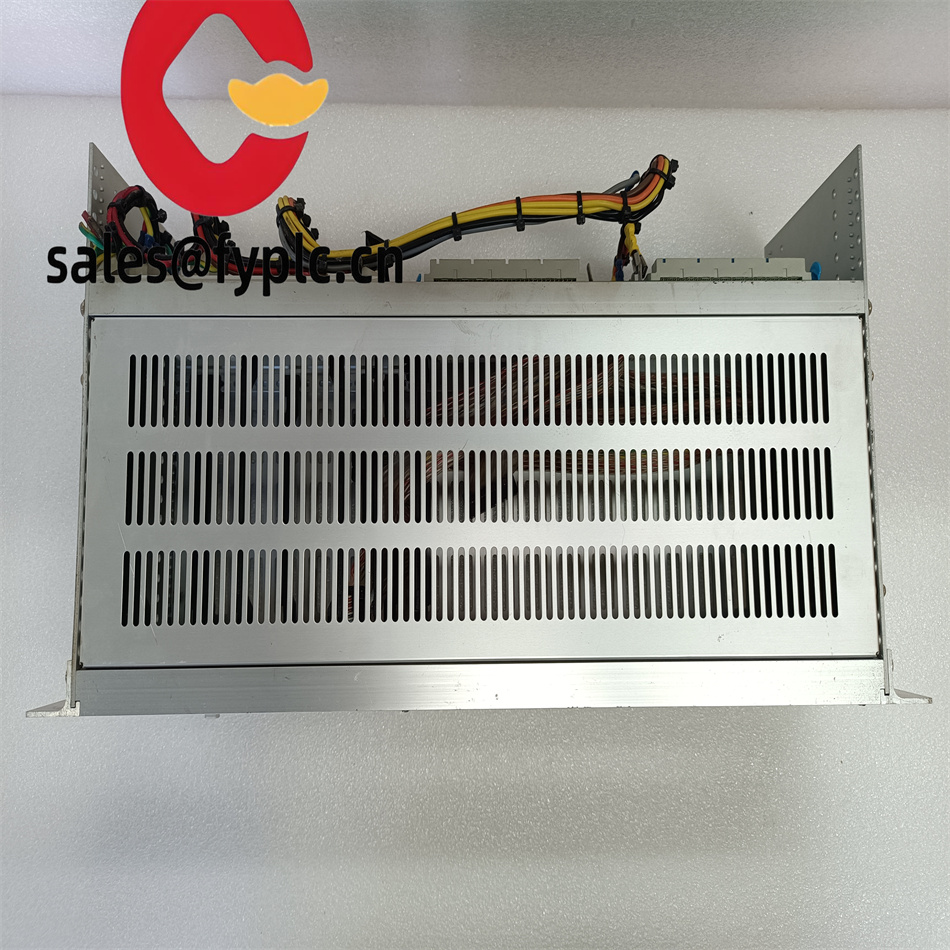

GE WESCOM D200 VME System Framework Power Interface Module

In the dynamic realm of industrial automation, the GE WESCOM D200 VME stands as a testament to innovation and reliability. This advanced VME (VersaModule Eurocard) controller module is meticulously engineered to elevate the performance of industrial control systems. Designed for demanding environments where precision and continuous operation are non-negotiable, the GE WESCOM D200 VME serves as the backbone for a wide array of automation setups, from complex distributed control systems (DCS) to sophisticated supervisory control and data acquisition (SCADA) networks. Its seamless integration capabilities and robust functionality make it a go-to choice for engineers and operators seeking to optimize efficiency and enhance system reliability.

The GE WESCOM D200 VME isn’t just another module; it’s a solution that empowers industries to overcome the challenges of modern automation. Whether it’s managing critical processes in manufacturing plants, ensuring smooth operations in power generation facilities, or overseeing intricate workflows in chemical processing units, this module has the versatility to adapt and perform. With its cutting-edge technology, it enables real-time data processing and control, facilitating faster decision-making and more responsive systems.

What truly sets the GE WESCOM D200 VME apart in the industrial landscape is its remarkable functional strengths and design advantages. Engineered with speed in mind, this module can process large volumes of data in milliseconds, ensuring minimal latency in control loops. Its resilience is unparalleled, with the ability to withstand harsh environmental conditions, electrical interference, and mechanical vibrations. This makes it ideal for deployment in industrial settings where reliability is key.

Interoperability is another area where the GE WESCOM D200 VME shines. It seamlessly integrates with a wide range of existing systems and devices, allowing for easy expansion and upgrade of automation setups. The high build quality of the module ensures long-term durability, reducing the need for frequent replacements and minimizing downtime. Operators benefit from its intuitive interface, which simplifies configuration and maintenance, enabling them to focus on optimizing system performance rather than grappling with complex technicalities.

The GE WESCOM D200 VME finds its home in numerous industrial use cases, delivering significant value across different sectors. In manufacturing plants, it plays a crucial role in coordinating production lines, ensuring each machine operates in harmony to maximize output and minimize waste. By precisely controlling motors, sensors, and actuators, it helps maintain consistent product quality and reduces the risk of costly errors.

In power generation facilities, this module is integral to monitoring and controlling power generation processes. It enables real-time tracking of generator performance, voltage regulation, and load distribution, contributing to the stable and efficient supply of electricity. In SCADA systems, the GE WESCOM D200 VME facilitates seamless communication between field devices and the control center, providing operators with accurate and up-to-date information for informed decision-making. This ultimately enhances process reliability and operational efficiency, leading to improved productivity and reduced operational costs.

When considering compatible and related models, the GE WESCOM portfolio offers several options. GE WESCOM D300 VME is a high-performance variant that provides enhanced processing power, making it suitable for more complex automation tasks. GE WESCOM D150 VME is a compact alternative, perfect for applications where space is at a premium but reliable control is still essential. GE WESCOM D250 VME offers additional communication interfaces, enabling greater connectivity in diverse automation environments. GE WESCOM D400 VME stands out with its advanced security features, safeguarding critical industrial control systems from cyber threats. GE WESCOM D100 VME is an entry-level model that offers basic control functionality at an affordable price point, ideal for small-scale automation projects.

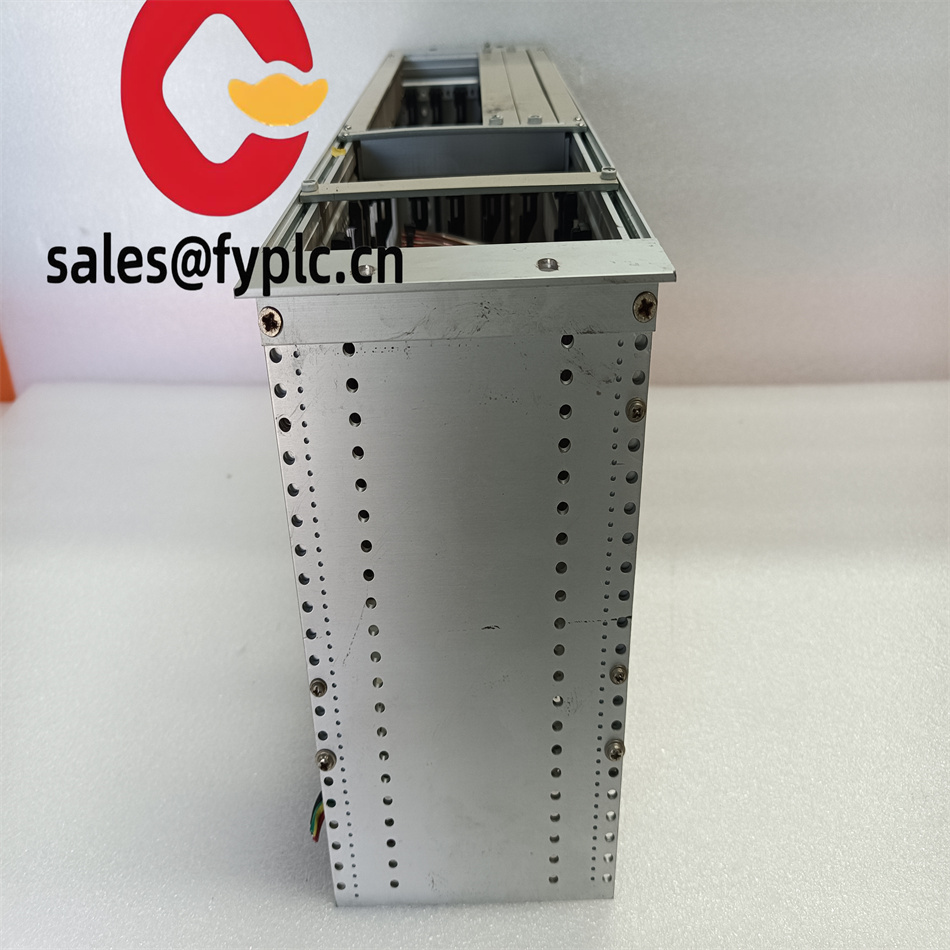

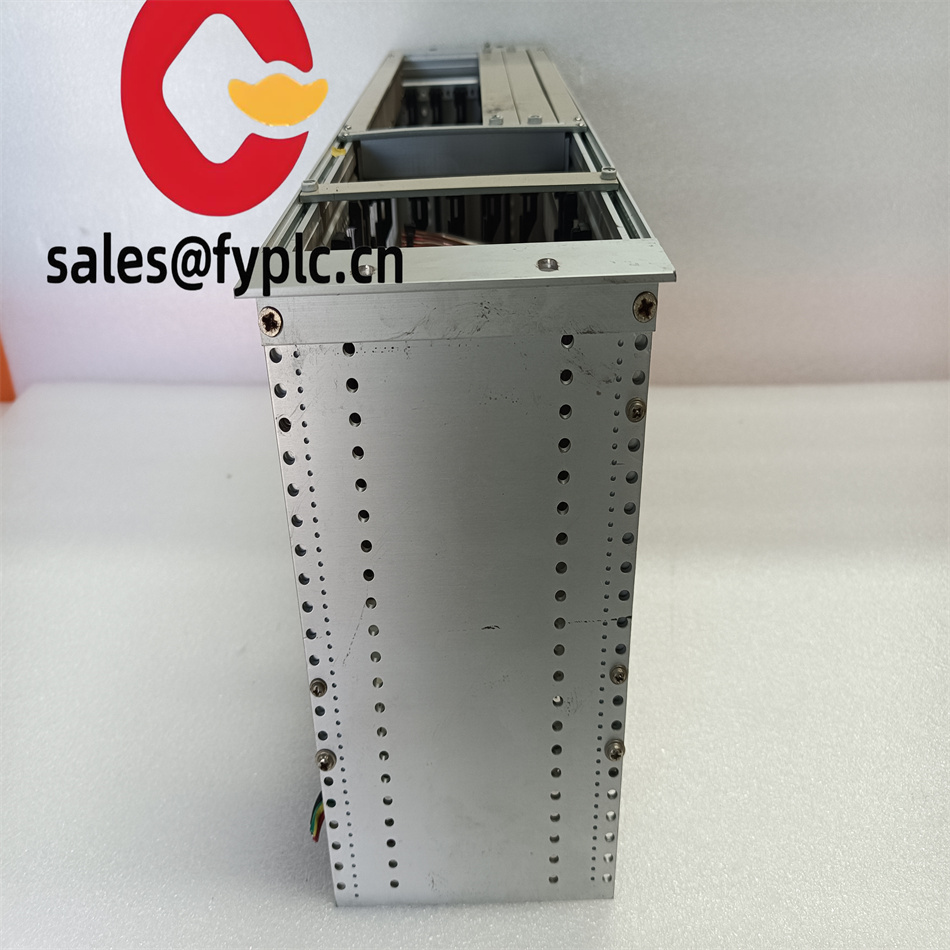

Installing the GE WESCOM D200 VME requires careful attention to a few key aspects. When mounting it in a VME rack, ensure proper alignment and secure fastening to prevent any movement that could lead to connectivity issues. Adequate grounding is essential to protect the module from electrical surges and ensure stable operation. Also, consider the airflow around the module; proper ventilation helps maintain optimal operating temperatures and prolongs the lifespan of the component.

For long-term operation, regular inspections are recommended. Check for any signs of physical damage, loose connections, or abnormal heat generation. Periodically update the module’s firmware to benefit from the latest features, performance improvements, and security patches. By following these maintenance practices, you can ensure the GE WESCOM D200 VME continues to perform reliably over time.

GE WESCOM stands firmly behind the GE WESCOM D200 VME with a comprehensive warranty and world-class support coverage. The manufacturer’s confidence in the product’s durability is evident, as it offers a generous warranty period that provides peace of mind to buyers. In addition to the warranty, customers have access to a global network of technical support experts who are ready to assist with any queries or issues. Extensive documentation, including user manuals and troubleshooting guides, is available to help users get the most out of the module. With remote support options, GE WESCOM ensures that help is just a click away, further enhancing customer assurance and long-term reliability of the GE WESCOM D200 VME.

For more information, please click below to learn more:

Reviews

There are no reviews yet.