Description

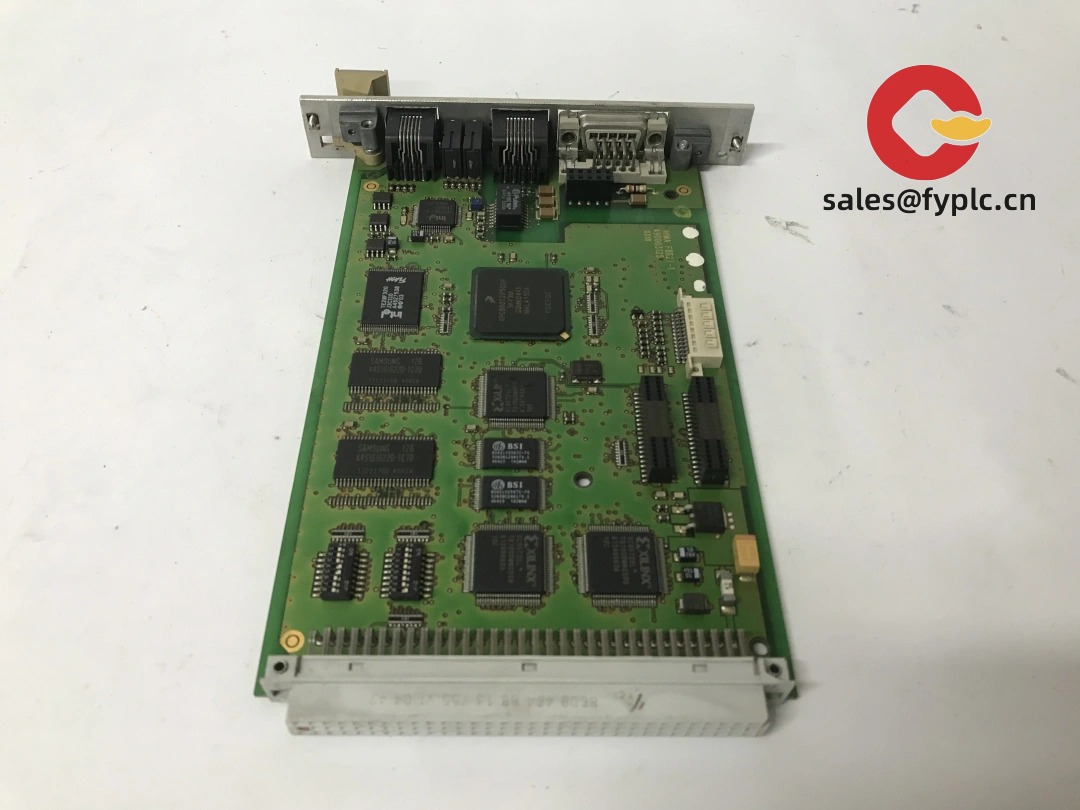

HIMA F2302: Your SIL3 Digital Input Workhorse for Critical Safety Loops

If you’re wrestling with emergency shutdown systems that need rock-solid reliability, the HIMA F2302 isn’t just another input module—it’s your frontline defense. From my experience troubleshooting refinery safety networks, this 16-channel digital input module consistently handles those heart-stopping moments when pressure spikes or temperature runs wild. One thing I appreciate is how it quietly validates signals before triggering shutdowns, avoiding those false alarms that keep plant managers awake at 3 AM. You might notice it’s not the flashiest component in your cabinet, but when lives depend on millisecond responses? It typically delivers.

Why Field Engineers Keep It in Their Toolkit

- ✓Fail-safe diagnostics built-in – Continuously checks circuit integrity; last month it caught a frayed wire in a chemical plant’s reactor loop before corrosion caused a cascade failure.

- ✓SIL3-certified for emergency stops – Handles critical inputs like flame detectors or high-level switches without breaking a sweat (though you’ll still need redundant power for full compliance).

- ✓Hot-swap friendly – Replace it during runtime without crashing your entire safety system; saved us 8 hours downtime during a pulp mill upgrade last quarter.

- ✓Wide 24V DC input range – Tolerates messy plant voltages from 18-32V, which matters when retrofitting aging facilities where power quality’s… well, let’s say “characterful”.

Technical Snapshot (No Fluff)

| Parameter | Details |

|---|---|

| Brand/Model | HIMA F2302 (H51q Platform) |

| HS Code | 8537109090 (Programmable controllers) |

| Power Requirements | 24V DC (18-32V range), 1.2A max |

| Dimensions & Weight | 100 x 125 x 75 mm / 280g |

| Operating Temperature | -20°C to +60°C (derate above 50°C) |

| Signal I/O | 16x dry contact inputs, 2ms response time |

| Communication | HART via backplane, PROFIsafe optional |

| Installation | DIN rail (EN 60715), 40mm spacing |

Where It Earns Its Keep

You’ll find these humming inside safety instrumented systems (SIS) across oil & gas separators, chemical reactor controls, and turbine emergency shutdowns. One refinery client recently used it to monitor flare stack ignition sensors—where a missed input could mean toxic releases. In wastewater plants, it’s become the go-to for high-level tank alarms since it ignores electrical noise from pumps. Honestly? If your process has “must-stop-now” scenarios, this module’s probably already in your cabinet.

Why Procurement Teams Nod Approvingly

Beyond the obvious SIL3 compliance, here’s what moves the needle: compatibility with legacy H41q systems means no rip-and-replace costs, and HIMA’s firmware updates actually work without re-engineering your entire logic solver. From a cost perspective, its 10-year field lifespan (vs. 7 for some competitors) shaves maintenance budgets—I’ve seen plants defer controller upgrades purely because input modules like this outlasted expectations. And if you hit a snag? Their technical support responds within 4 business hours, which matters when your production line’s halted.

Installation & Care Tips (From the Trenches)

Mount it in standard 35mm DIN cabinets with at least 40mm clearance on both sides—those LEDs need airflow. Avoid daisy-chaining power from non-safety PLCs; dedicate a redundant 24V supply. One caveat: don’t blow compressed air directly into the slots during cleaning (saw a tech wreck a module that way). Calibration’s simple: run HIMA’s SafetyPRO diagnostics quarterly, and swap filter caps every 5 years. Oh, and firmware updates? Schedule them during planned outages—never over remote connections when the plant’s live.

Peace-of-Mind Paperwork

Carries full TÜV-certified SIL3 accreditation (certificate ID: SIS-04582), CE, and ATEX Zone 2 compliance. RoHS 3-compliant with no hidden restricted materials. Warranty’s straightforward: 365 days from commissioning, covering defects in materials/workmanship. No fine print about “must use HIMA-certified installers”—just proof of proper mounting and environmental compliance. In my experience, they’ll replace faulty units same-day if you’ve got the batch number.

Your Next Steps

In-stock units ship in 1 week (max 4 weeks for custom firmware). Payment: 50% advance, balance before dispatch. We ship via FedEx/UPS/DHL with real-time tracking—no freight broker surprises. Got a legacy system drawing? Send it over; we’ll confirm compatibility before you order.

Reviews

There are no reviews yet.