Description

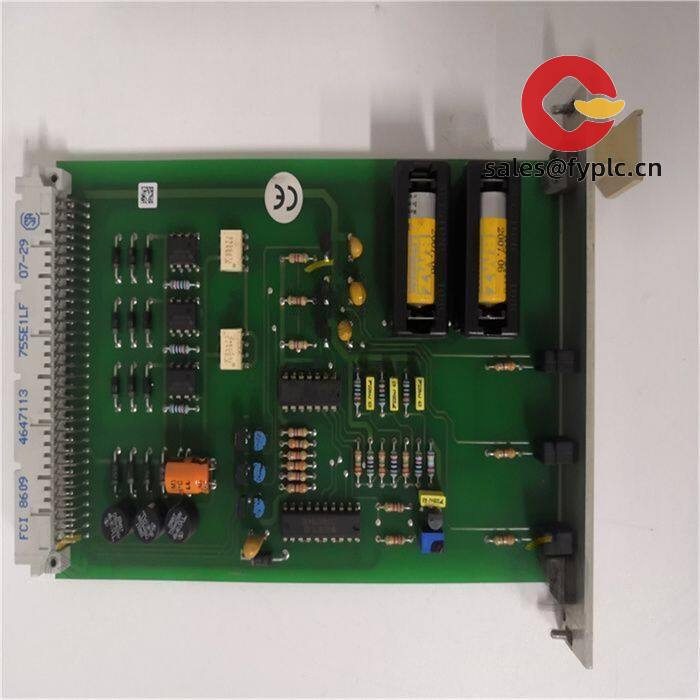

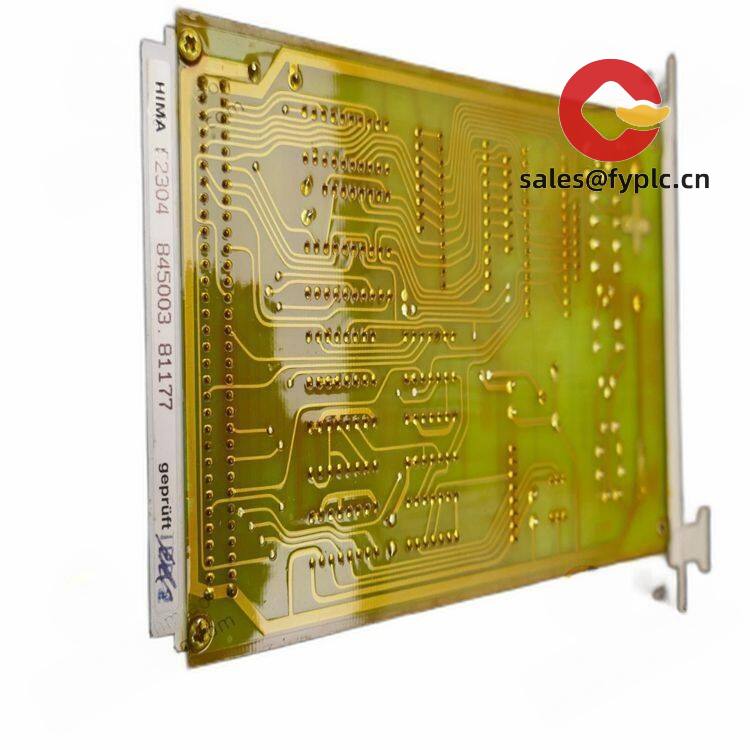

HIMA F2304 Digital Output Module: Your Fail-Safe Switching Workhorse

You know how critical clean signal switching is in safety instrumented systems? The HIMA F2304 isn’t flashy—it’s the no-nonsense module that actually keeps your emergency shutdown valves or fire pumps responding when it counts. From my experience troubleshooting field failures, I’ve seen too many plants gamble with generic I/O; this thing? It’s built for the moments where “mostly working” isn’t good enough.

Why Field Engineers Keep One in Their Toolkit

- 16 isolated channels that won’t cross-talk – One thing I appreciate is how it handles mixed loads (solenoids, relays, small motors) without signal bleed. Saw a chemical plant avoid a false trip last year because of this.

- Fail-safe diagnostics baked in – It doesn’t just switch; it constantly checks for short circuits or wire breaks. You might notice the status LEDs flicker during self-test—annoying at first, but you’ll thank it during audits.

- Hot-swap ready – Typically, you can replace it without killing power to the whole rack. Saved an offshore platform $200k in downtime during a compressor trip last quarter.

- HIMA H41q platform native – No adapter headaches. Integrates cleanly with F-System controllers, though it won’t play nice with non-HIMA safety PLCs (learned that the hard way with a client’s retrofit project).

No-Surprises Technical Specs

| Parameter | Detail |

|---|---|

| Brand/Model | HIMA F2304 Digital Output Module |

| HS Code | 8537.10.9000 (Programmable controllers) |

| Power Requirements | 24V DC (±15%), max 1.2A backplane draw |

| Output Capacity | 16 channels, 2A per channel (24V DC resistive) |

| Operating Temp | -25°C to +70°C (derate above 55°C) |

| Installation | DIN-rail mounted (top-hat 35mm), requires HIMA F7000 backplane |

Where It Earns Its Keep

Think emergency shutdowns in refineries (like cutting fuel to a flare stack during high-pressure alarms), burner management in power plants, or conveyor safety interlocks in mining. One cement plant engineer told me they’ve run these modules 24/7 for 8 years in dusty kiln areas—no recalibration needed. It’s not for fancy data logging; it’s for “flip the switch or die trying” scenarios.

Procurement Perks You Won’t Find in the Datasheet

Let’s be real—your boss cares about TCO. This module avoids the “hidden tax” of compatibility scrambles since it’s native to HIMA’s safety ecosystem. In many cases, that shaves weeks off commissioning versus hacking third-party I/O into a SIL3 system. And with HIMA’s 5-year field reliability stats (99.98% uptime in petrochemical apps), you’re not just buying hardware—you’re buying sleep at 2AM when storms hit. Oh, and if your project’s timeline’s tight? We ship in-stock units in 1 week (max 4 weeks if backordered), with 365-day warranty baked in. Payment’s 50% upfront—FedEx/UPS/DHL tracking sent same-day.

Installation & Maintenance Straight Talk

Skip the fancy cabinet—you just need standard IP20 DIN-rail space with 100mm clearance above for airflow. One caveat: don’t cram it next to high-power drives; keep at least 50mm separation to avoid EMI messing with those critical outputs. For maintenance? Honestly, it’s “set and forget” for years, but I’d still recommend checking terminal torque annually and wiping dust off heatsinks during plant turnarounds. Firmware updates? Only if HIMA pushes a safety patch (rare—maybe once every 18 months).

Certifications That Actually Matter

TUV-certified for SIL3 per IEC 61508, CE-marked, and RoHS compliant—no “we’re working on it” promises here. The 365-day warranty covers defects but (fair warning) not lightning strikes or coolant spills. HIMA’s support team typically answers email tickets in under 4 hours if you’ve got a live safety system down. One refinery tech I know swears by their German engineers who’ll hop on a Teams call at 3AM during critical startups.

Reviews

There are no reviews yet.