Description

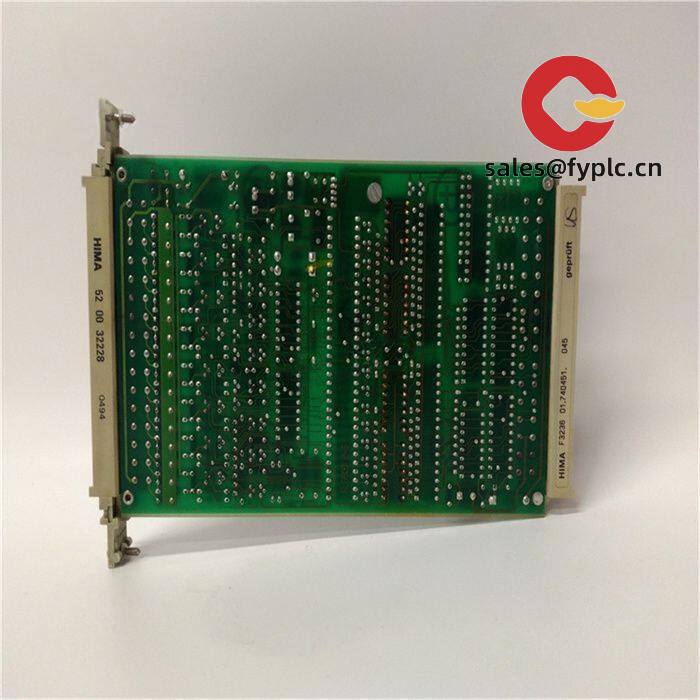

HIMA F3 AIO 8 01 (F3AIO8401) – Safety‑related Analog I/O Module for HIQuad/F3 Systems

The HIMA F3 AIO 8 01, often referenced as F3AIO8401, is a safety‑related analog input/output module designed for HIMA F3/HIQuad systems. From my experience, it’s typically used when you want a compact, SIL‑oriented analog card that can be configured as current or voltage for both inputs and outputs, without redesigning the cabinet. You might notice that it slots directly into F3 racks and communicates over the backplane, so integration is straightforward for existing H41q/H51q/HIQuad installations.

Order Placement Process & Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment, full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- Safety‑related analog I/O in one card: Combines analog inputs and outputs, typically configurable for current or voltage loops to reduce slot count.

- 8 configurable channels: In many cases set as 4–20 mA or 0–10 V; helps standardize field signals across ESD/BMS loops.

- SIL‑focused design: Engineered for safety applications; suitable for SIL 3 architectures when used as specified in HIMA documentation.

- Backplane integration: Communicates via the F3/HIQuad backplane—no extra comms wiring to the CPU.

- Diagnostics & status LEDs: Quick visual state makes loop checks and fault isolation faster during turnarounds.

- HIMA ecosystem compatibility: Works within H41q/H51q/HIQuad systems, preserving existing cabinet layouts and wiring practice.

- Serviceable front connector: Front plug connector simplifies commissioning and module swaps without disturbing field terminations.

Technical Specifications

Note: Specific limits vary by firmware and system configuration. If you need confirmed resolution, accuracy, or channel assignment tables, we’ll check against your exact CPU/rack revision.

Application Fields

- Process Safety (SIS): ESD, HIPPS, and critical interlocks in refineries and petrochemical units where 4–20 mA loops dominate.

- Burner Management: Analog monitoring of fuel/air and temperature with tight trip thresholds.

- Power & Turbomachinery: Turbine lube oil pressure, vibration, and temperature loops tied into safety logic.

- Pharma & Fine Chemicals: Validated safety loops needing stable analog measurement under regulated environments.

- Tank Farms & Pipelines: Level/pressure analog signals for overfill protection and shutdown functions.

Advantages & Value

- Drop‑in compatibility: Keeps your F3/HIQuad architecture intact—no need to requalify a new platform.

- Fewer slots, more flexibility: Combined AI/AO on one card typically reduces cabinet footprint and spare part inventory.

- SIL‑minded lifecycle: Proven in safety applications; documentation and proof‑test support are readily available.

- Lower total cost of ownership: Standard signal ranges and front connector design help shorten commissioning and turnaround time.

- Support when you need it: We help match the module to your CPU/rack revision and advise on safe channel configuration.

A maintenance lead at a Gulf Coast refinery told us their swap to F3 AIO cards “cut our loop checkout time by a day” because the status LEDs and consistent connectors kept things simple. That seems to be a common pattern in brownfield projects.

Installation & Maintenance

- Cabinets & environment: Mount in a suitable enclosure with adequate ventilation; avoid vibration and corrosive atmospheres.

- Power & grounding: Use clean 24 VDC (prefer redundant feeds where possible). Maintain low‑impedance protective grounding.

- Wiring: Shielded twisted pairs for analog loops; land shields at one end to minimize ground loops. Verify polarity on current loops.

- Hot‑swap practice: Follow HIMA guidelines; isolate field circuits where required before removing the front connector or module.

- Routine maintenance: Periodic proof testing per SIS procedures, terminal retorque checks, dust cleaning, and firmware checks/updates as recommended.

- Calibration: Where accuracy is critical, perform loop calibration against certified test equipment at defined intervals.

Quality & Certifications

- Safety: Designed for use in SIL 3 applications per IEC 61508 when applied in approved architectures.

- Compliance: CE marked; RoHS compliant according to typical HIMA product conformity.

- Manufacturing quality: Produced under ISO 9001 quality systems.

- Warranty: 365‑day warranty coverage from shipment.

Related & Supporting Components

- HIMA H41q/H51q Controllers: Typical CPUs used in HIQuad systems hosting F3 I/O modules.

- F3 Racks & Backplanes: Standard F3/HIQuad subracks providing power and data backplane for modules.

- Front Plug Connectors: Removable terminal connectors for fast field wiring and maintenance.

- Analog Input/Output Signal Conditioners: For long cable runs, loop isolation, or special ranges ahead of the F3 AIO channels.

If you share your rack type, CPU model, and desired channel mapping (AI vs. AO, current vs. voltage), we’ll verify compatibility, advise on proof‑test intervals, and confirm the exact order code to match your installed base.

Reviews

There are no reviews yet.