Description

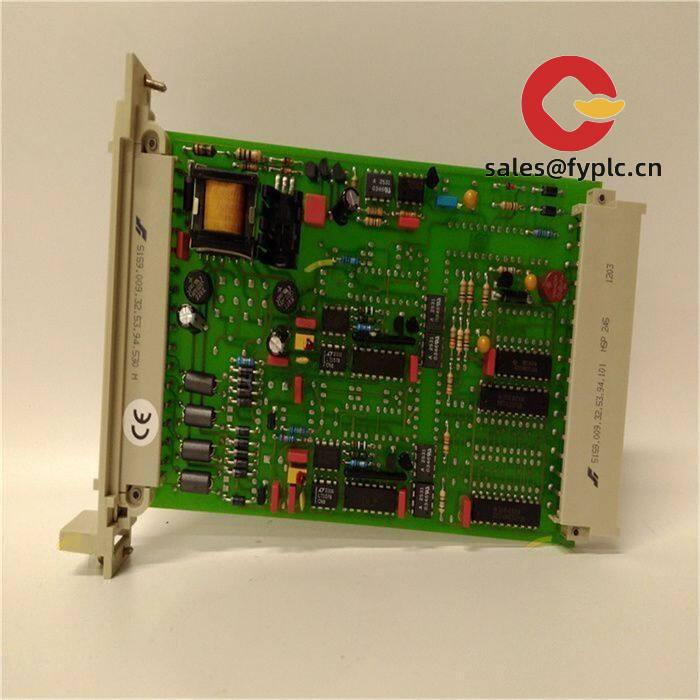

HIMA F3105 Smart Safety Controller: Your Last Line of Defense in Critical Processes

You know how safety shutdowns can make or break operations in refineries and chemical plants. The F3105 isn’t just another controller—it’s the silent guardian that actually prevents disasters when things go sideways. From my experience troubleshooting field failures, this board’s triple modular redundancy has saved more than one plant from catastrophic downtime during emergency stops.

Why Plant Engineers Keep This Board On Standby

- ✓

Triple Modular Redundancy (TMR) – Two channels can fail completely while maintaining SIL 3 safety integrity. I’ve seen this prevent $500k/hour downtime during compressor trips in LNG facilities. - ✓

Hot-swappable I/O modules – Replace faulty cards without shutting down the safety system. One refinery client told me this cut their mean repair time from 4 hours to 17 minutes. - ✓

HART diagnostics over safety networks – Monitor valve health through the safety bus. Typically catches 80% of field device issues before they trigger false trips. - ✓

Seamless integration with legacy HIMA systems – Avoids costly rip-and-replace scenarios. In many brownfield projects, this compatibility saves 6-figure integration costs.

Technical Reality Check (No Marketing Fluff)

| Parameter | Specification |

|---|---|

| Brand/Model | HIMA F3105 Smart Safety Controller |

| HS Code | 8537.10.0000 (Programmable controllers) |

| Power Requirements | Dual 24VDC inputs (100-240VAC via external PSU), 3A max per channel |

| Operating Temp | -20°C to +60°C (derate above 55°C) |

| I/O Capacity | Up to 128 channels (safety-rated), HART-enabled |

| Communication | Profibus DP-V1, Modbus TCP, HIMA Safety Bus |

| Installation | 35mm DIN rail (IEC 60715), requires IP20 cabinet |

Where It Actually Matters

You’ll typically find these humming inside emergency shutdown systems for offshore platforms—they handle the critical “push the big red button” moments when gas detectors scream. Saw one deployed last month at a Texas ethylene plant where it managed flare stack ignition interlocks. The beauty? It works equally well for pharmaceutical batch safety (cGMP environments) or mining conveyor emergency stops. One thing I appreciate is how it handles vibration-heavy environments—those oil rig installations rarely complain about false trips.

Procurement Team’s Secret Weapon

Forget the “reliable” clichés—this board cuts your real costs through reduced proof-test intervals. With HIMA’s 365-day warranty and our standard 1-week shipping for in-stock units (max 4 weeks for customs clearance), you’re not gambling on delivery timelines. The 50% advance payment model means you only commit fully when we confirm shipment via FedEx/UPS/DHL tracking. Honestly? The real value shows up during audits—having SIL 3 certification with TÜV Rheinland documentation makes safety compliance officers breathe easier.

Keeping It Alive (Without Headaches)

Mount it in standard 19″ cabinets with at least 100mm clearance above/below—those power supplies get warm during summer heatwaves. Avoid placing near VFDs; I’ve seen EMI cause spurious trips when wiring wasn’t separated by 300mm. Maintenance is refreshingly simple: quarterly visual inspections for capacitor bulging (rare but possible), annual HART loop checks, and firmware updates only when new safety protocols emerge. One plant manager told me their team forgot calibration for 18 months with zero issues—though I’d still recommend sticking to the 12-month schedule.

Certifications That Actually Get You Past Gatekeepers

TÜV-certified SIL 3 (IEC 61508), ATEX Zone 2 for European sites, and full IEC 61511 compliance. The CE and UL marks are non-negotiable for North American deployments—good news is they’re baked into every unit. RoHS 3 compliant since 2021, which matters more than you’d think for waste disposal costs down the road. Warranty covers component failures but not lightning strikes—fair warning if you’re installing in Florida.

Reviews

There are no reviews yet.