Description

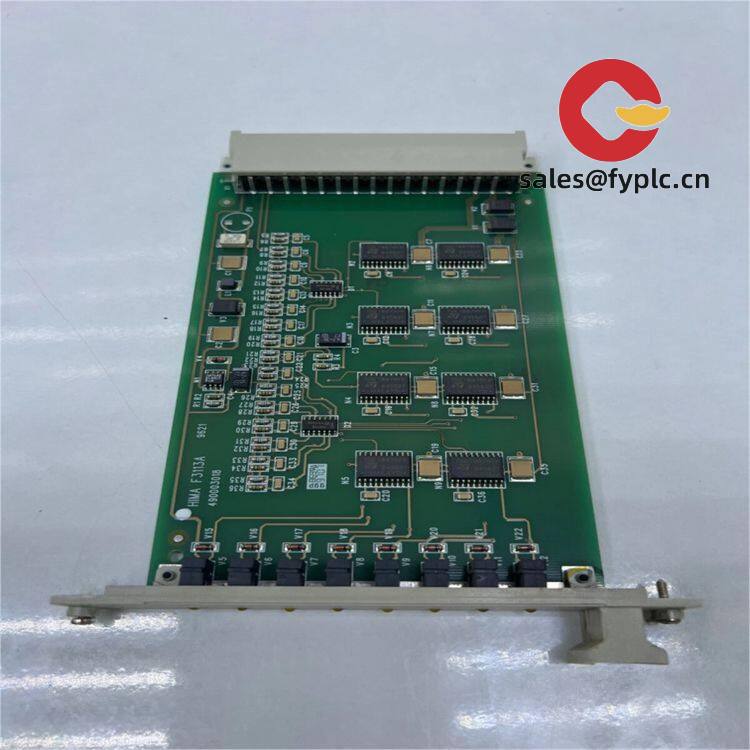

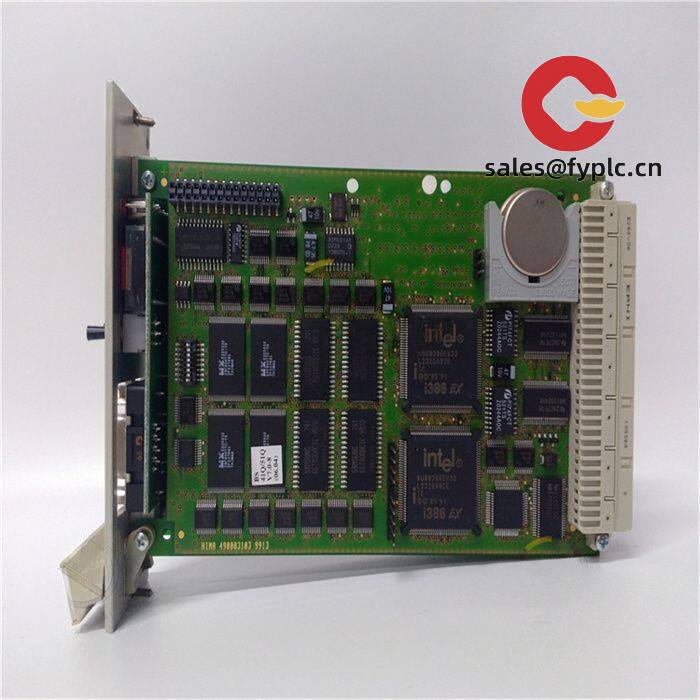

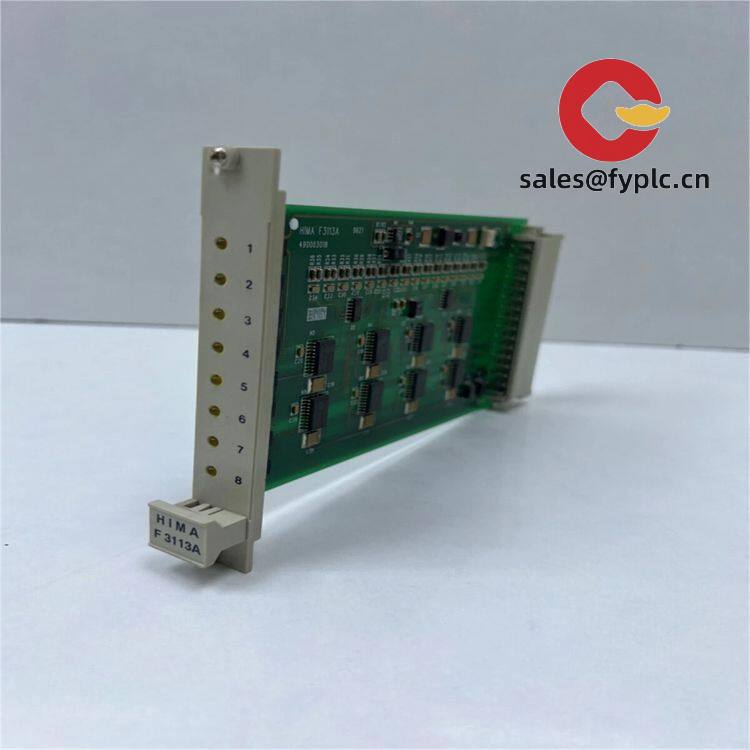

HIMA F3113 Output Module – Safety Digital Outputs for Reliable Machine and Process Control

The HIMA F3113 is a safety-rated output module designed for use in HIMA safety systems, typically within HIQuad-family racks. From my experience, it’s chosen when engineers need dependable 24 VDC digital actuation for solenoids, contactors, beacons, or shutdown valves, while keeping SIL-compliant behavior and clear diagnostics. You might notice that maintenance teams appreciate its straightforward channel status LEDs and the way it integrates with the backplane—less guesswork, quicker recovery.

Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week for in‑stock items; no more than one month at the latest

- Payment terms: 50% advance payment; full payment prior to delivery

- Express shipping: FedEx, UPS, DHL

Key Features

- Safety-rated digital outputs: Designed for use in HIMA safety systems to achieve up to SIL 3 when applied within a certified architecture.

- 24 VDC field actuation: Suits common industrial loads such as solenoid valves, interposing relays, lamps, and sounders.

- Channel diagnostics: Typically supports status indication and fault reporting to reduce troubleshooting time during turnarounds.

- Galvanic isolation: Isolation between field channels and system bus helps minimize cross-channel interference and improves robustness.

- Backplane integration: Seamless communication over the HIMA rack backplane—no external configuration port required on the module itself.

- Service-friendly design: Clear front labeling and LEDs; in many cases, field wiring stays on the terminal connector for faster swap-outs.

- Long lifecycle support: Stable availability and strong spares strategy make it suitable for process safety upgrades or phased migrations.

Technical Specifications

| Brand / Model | HIMA F3113 |

| HS Code | 8538.90 (Parts for industrial control apparatus) |

| Power Requirements | Backplane-powered module; 24 VDC field supply for output loads |

| Signal Output Type | Safety digital outputs, 24 VDC (typical high-side switching) |

| Communication Interface | HIMA system backplane (no front Ethernet/serial port on the module) |

| Installation Method | Plug-in module for HIMA rack/baseplate; front terminal connector for field wiring |

| Operating Temperature | Industrial range, typically −20 to +60 °C |

| Dimensions & Weight | Single-slot F3 form factor; lightweight module |

| System Compatibility | Designed for HIMA safety systems (commonly used with HIQuad-family racks) |

Application Fields

The F3113 is well-suited to safety instrumented functions that need deterministic, monitored actuation:

- Process shutdown and ESD solenoid control in oil & gas and petrochemical units

- Boiler and turbine auxiliary trips in power generation

- Emergency ventilation, fire & gas beacons and sounders

- Interlocks for machinery, conveyors, and high-integrity motion stops

- Tank farm and pipeline block valve actuation

A maintenance supervisor at a refinery told me their team liked that “channel faults were obvious from the front LEDs,” and it trimmed minutes off isolation and proof-test routines. It seems small, but during shutdown windows, those minutes matter.

Advantages & Value

- Reliability in safety loops: Built for safety control where availability and diagnostic coverage are critical.

- Seamless HIMA integration: Minimizes engineering effort—no extra gateways or protocol converters.

- Lifecycle cost control: Consistent firmware and spare-parts strategy typically reduce unplanned downtime and stock complexity.

- Service & know‑how: We help match module channel types and load characteristics to your SIF design to avoid nuisance trips.

Installation & Maintenance

- Cabinet & mounting: Install in a clean, ventilated control cabinet. Maintain adequate spacing for airflow and cable bend radius. Use the specified HIMA rack/baseplate and secure the module to avoid vibration issues.

- Power & wiring: Provide a stable 24 VDC field supply for loads. Route field wiring separately from high-noise power cabling; use shielded cables for long runs and bond shields at a single point. Protect each output loop with appropriate fusing.

- Grounding: Ensure proper system grounding and segregation of safety and non-safety circuits according to site standards.

- Commissioning: Verify channel mapping in the safety application, perform point-to-point checks, then carry out proof-tests per your SIL verification plan.

- Service tips: Use front LEDs and system diagnostics to localize faults. Module replacement is straightforward; in most cases the field terminal connector can remain wired to speed swap.

- Maintenance: Periodically inspect terminals for torque/oxidation, clean dust with dry compressed air, and align firmware and configuration management with your change-control process.

Quality & Certifications

- Designed for use in IEC 61508 SIL-classified applications (up to SIL 3 when used in a certified HIMA architecture)

- CE marking for EMC and safety (typical for HIMA modules)

- UL/cUL where applicable

- RoHS-compliant construction

- Manufacturer’s warranty: 365 days

Related/Supporting Components (for a complete build)

- HIMA safety CPU (HIQuad-family controller)

- Compatible HIMA rack/baseplate and power supply module

- Detachable terminal connectors for field wiring

- Relay interposing panels (when switching higher currents or AC loads)

- Certified 24 VDC power supply and fused distribution

If you share the channel count you need and the load profile (solenoid type, inrush, trip time), I can suggest the best mix of F3113 modules and any interposing hardware to keep your proof-test intervals and spares simple.

Reviews

There are no reviews yet.