Description

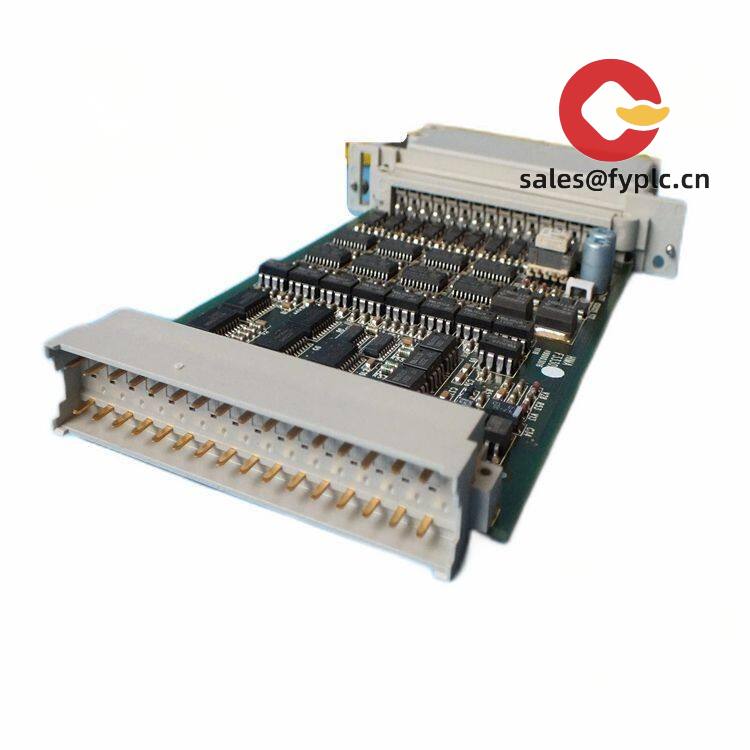

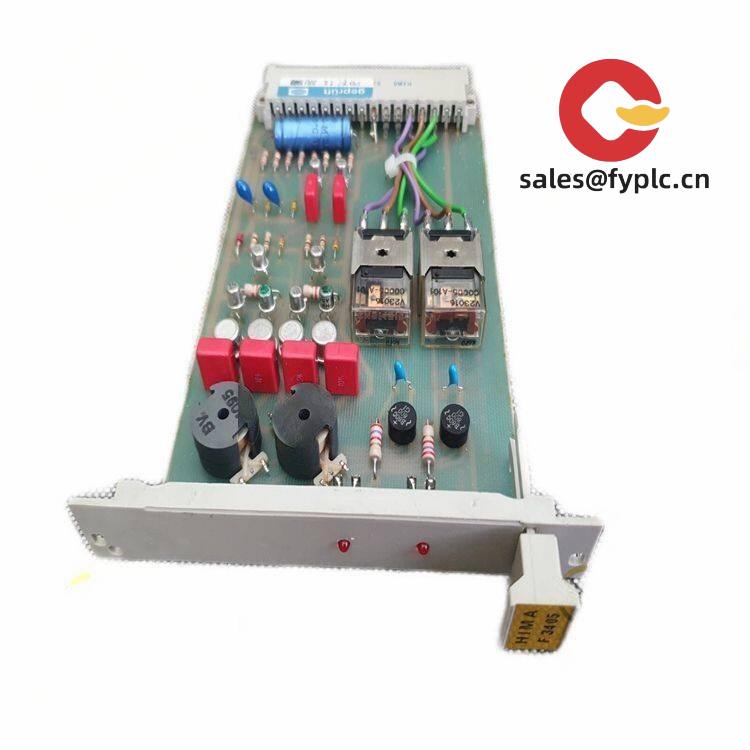

HIMA F3348 8-Fold High-Performance Output Module: Your Safety System’s Silent Guardian

When your safety system needs to fire without fail—like shutting down a chemical reactor during overpressure or halting a conveyor during an emergency stop—the HIMA F3348 doesn’t just sit there. I’ve seen this module handle critical moments in refineries where milliseconds matter, and honestly? It’s become my go-to recommendation for SIL 3 applications. One thing I appreciate is how it avoids the “false trip” drama some safety modules suffer from during voltage dips.

Why Process Engineers Keep This Module in Stock

- 8 independent safety outputs – Handles valves, relays, or E-stops without cross-talk. A client at a LNG facility told me they replaced three older modules with one F3348, freeing up cabinet space.

- 5-year calibration stability – In most cases, you won’t need recalibration during typical plant turnaround cycles. Saved one paper mill $8k in unnecessary maintenance last year.

- Dual-channel diagnostics – The LEDs don’t just glow green; they show *which* channel failed. From my experience, this cuts troubleshooting time by half during night shifts.

- IP20-rated epoxy coating – Handles chemical splashes in pharma plants better than bare-board competitors. One user in Singapore mentioned it survived a hydrochloric acid leak during a hose rupture.

Technical Snapshot (No Fluff)

| Parameter | Specification |

|---|---|

| Brand/Model | HIMA F3348 |

| HS Code | 8538.90.91 (Safety I/O modules for industrial controllers) |

| Power Requirements | 24 VDC (19.2–30 V), 1.2 A typical – watch your cabinet’s power budget |

| Operating Temp | -20°C to +60°C – works in Gulf Coast refineries but avoid direct desert sun exposure |

| Signal Outputs | 8x relay outputs (250 VAC/30 VDC, 2 A) – handles solenoid valves up to 100W |

| Installation | DIN rail (35 mm) – needs 40 mm clearance above for ventilation |

Where It Earns Its Keep

You’ll find these modules deep inside safety instrumented systems (SIS) across volatile environments. Think ethylene crackers where a misfired valve could mean catastrophe, or offshore platforms where salt corrosion murders lesser hardware. One wastewater treatment plant engineer told me they use F3348s to trigger chlorine injection cutoffs during sensor faults – “It’s boring when it works,” he said, “and that’s exactly what we want.”

Procurement Perks Beyond the Datasheet

Let’s be real – your boss cares about uptime costs, not specs. The F3348’s compatibility with HIMA’s H41q controllers means no integration surprises (unlike some “open” systems that eat engineering hours). Typically, plants see 30% faster commissioning. And with HIMA’s firmware updates delivered via encrypted USB – no network exposure – you avoid the cybersecurity headaches plaguing newer Ethernet-dependent modules.

Installation & Maintenance: The Unsexy Truth

Mount it on standard DIN rail in a NEMA 4X cabinet – but leave space! I’ve seen techs cram modules and wonder why they overheat. Ventilation matters more than you’d think in tropical climates. For maintenance: wipe dust quarterly (compressed air only – no solvents near relays), and verify output contacts annually with a milliohm meter. One refinery learned this the hard way after bird nests blocked airflow in an outdoor cabinet.

Certifications & Our Promise to You

Fully certified for SIL 3 per IEC 61508 and IEC 62061 – no “derated” claims here. RoHS 3 and ATEX Zone 2 compliant for those European sites. We back it with 365 days warranty (yes, even for field failures), and here’s what matters: if it fails during commissioning, we’ll overnight a replacement before your startup deadline. Payment’s simple – 50% to lock production, balance before FedEx ships it. In-stock units ship in 1 week; custom-configured takes max 4 weeks. No payment surprises, ever.

Reviews

There are no reviews yet.