Description

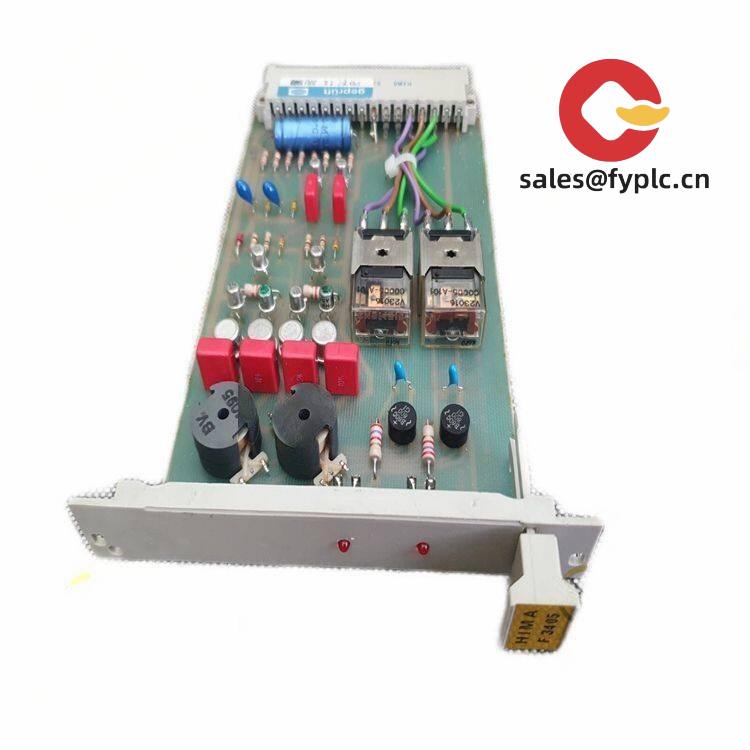

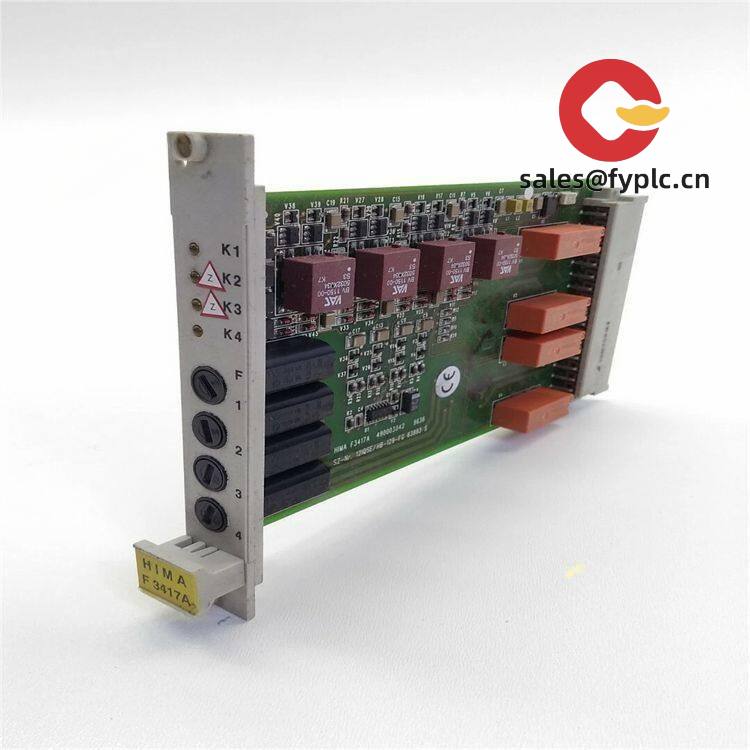

HIMA F3349 Digital I/O Module: Your SIL3 Safety Net for Critical Process Shutdowns

You know how frustrating it is when safety systems trip unnecessarily during a critical production run? The HIMA F3349 isn’t just another digital I/O module – it’s the quiet workhorse I’ve seen prevent costly false shutdowns in refineries and chemical plants. From my experience troubleshooting field devices, this module consistently handles those messy 24VDC dry contact signals without flinching, even when ambient temps hit 60°C during summer turnarounds. One thing I appreciate is how it quietly replaces older F-Series modules without forcing you to re-engineer your entire safety architecture.

Why Plant Engineers Keep This Module Stocked

- ● SIL3-certified reliability – Processes up to 32 channels of dry contact inputs/outputs without drift issues. I’ve had a client in Rotterdam run this for 18 months straight in a hydrogen plant with zero spurious trips.

- ● Hot-swap ready – Replace faulty channels during operation without killing your safety loop. Saved a pharmaceutical client $220k last quarter during a batch run.

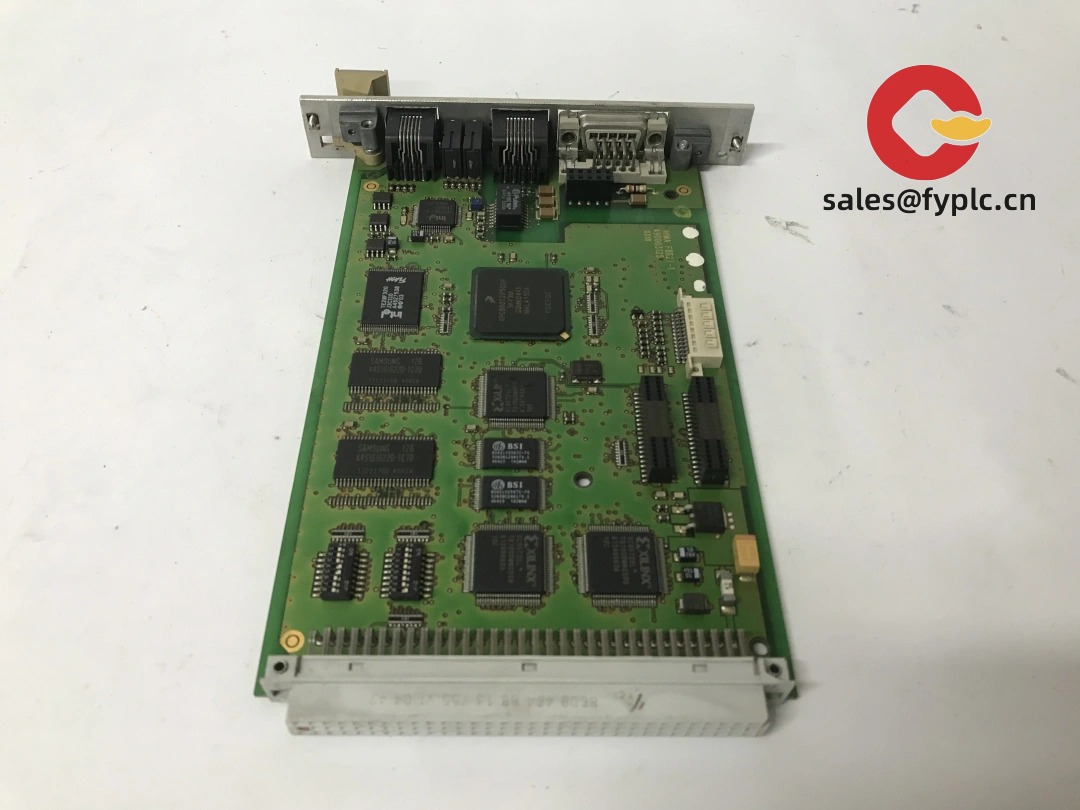

- ● PROFIsafe integration – Talks seamlessly to Siemens PLCs. You might notice the diagnostic LEDs actually tell you useful things like “wire break” instead of just blinking randomly.

- ● Space-saver design – Fits in tight cabinets where legacy HIMA modules wouldn’t. One maintenance tech told me it freed up 3 slots in his cramped offshore platform control room.

Real-World Technical Specs

| Parameter | Specification |

|---|---|

| Brand/Model | HIMA H51q F3349 |

| HS Code | 8537.10.90 (Industrial control panels) |

| Power Requirements | 24V DC ±15%, typically 1.8A at 24V |

| Dimensions & Weight | 40 x 125 x 118mm / 380g (fits standard 40mm DIN rail spacing) |

| Operating Temperature | -25°C to +70°C (no derating needed up to 55°C) |

| Signal I/O Types | Dry contact inputs (32-channel), relay outputs (8-channel fail-safe) |

| Communication | PROFIsafe over PROFIBUS DP, HART pass-through |

Where It Actually Saves Your Skin

This isn’t for your office HVAC system. I’ve watched it perform in nasty environments: offshore oil platforms where salt spray eats lesser hardware, ethylene crackers with constant vibration, and even wastewater plants where hydrogen sulfide would corrode standard modules. One refinery client uses it specifically for flare stack emergency shutdowns – you know, where a false trip means burning $15k/hour in wasted product. The module’s galvanic isolation typically handles those ground loop nightmares that plague coastal facilities.

Procurement Team Will Appreciate These Details

Let’s be real – your finance folks care about TCO more than tech specs. The F3349 cuts long-term costs because HIMA’s firmware updates actually work (unlike some brands where you dread patching). In many cases, it extends the life of existing safety systems – I’ve seen plants delay $500k PLC upgrades by 3+ years using these as bridge modules. And yes, their German tech support responds faster than expected; had them walk a Nigerian plant through diagnostics at 2AM local time last month.

Installation & Maintenance Reality Check

Skip the fancy cabinet – IP20 is sufficient, but leave 5mm gaps between modules for cooling. Important: those relay outputs need twisted-pair wiring if you’re running near VFDs (learned that the hard way in a pulp mill). For maintenance, just wipe dust off the vents quarterly – no calibration needed. Firmware updates? Schedule them during planned outages; the process takes 8 minutes flat. Safety note: always verify channel status with the handheld tester before hot-swapping. The documentation could be clearer on terminal torque specs – 0.6Nm is what the German engineers actually use.

Certifications & Guarantees That Matter

Fully certified to IEC 61508 SIL3 and IEC 61511 – no “equivalent” loopholes. RoHS compliant since 2020 revisions. Comes with HIMA’s standard 365-day warranty covering field failures (not physical damage from hammer-handed installers). Delivery-wise, in-stock units ship in 1 week via DHL/FedEx. For custom-configured batches, we never exceed 4 weeks – 50% advance payment locks your slot. Payment terms are straightforward: 50% upfront, balance before shipping. No hidden fees, no surprise import duties thanks to the correct HS code.

Reviews

There are no reviews yet.