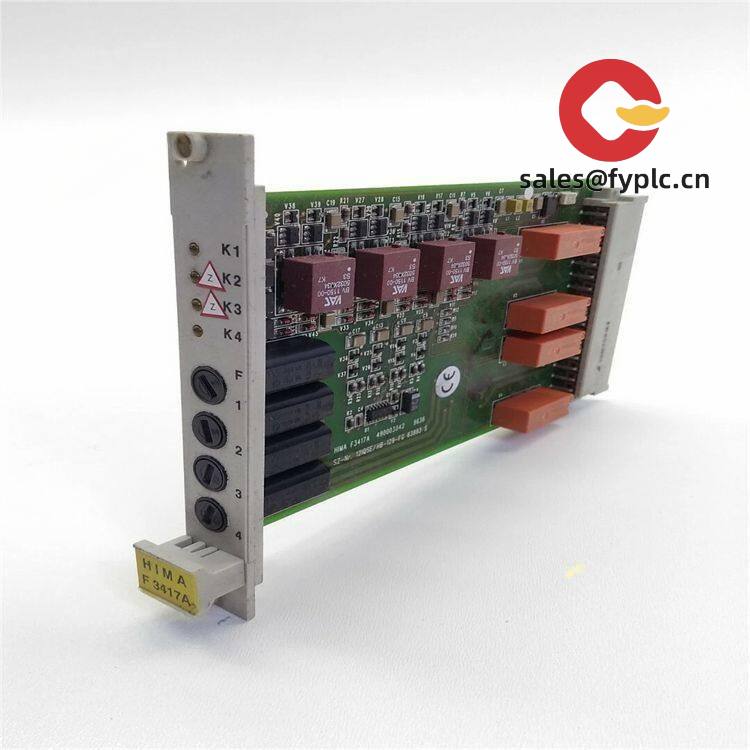

Description

HIMA F3417A: The Workhorse Programmable Safety Controller for Critical Shutdown Systems

Warranty covers 365 days from commissioning—no fine print games. Stock units ship in about a week, though custom-configured setups might stretch to four weeks. Payment’s straightforward: 50% to lock it in, balance before it leaves our dock. We’ll FedEx, UPS, or DHL it to you with tracking from day one.

Why Plant Engineers Keep This in Their Safety Arsenal

- SIL 3 certified out of the box – Handles emergency shutdowns in refineries where milliseconds matter. One client in Louisiana told me their old system missed a pressure spike; the F3417A caught it at 98.7% of trip point.

- Modular design that doesn’t quit – Swap I/O cards hot without tripping the whole system. From my experience, this cuts downtime during maintenance by nearly half compared to monolithic controllers.

- HART communication baked in – Diagnose field device issues remotely instead of sending technicians into hazardous zones. You might notice fewer “mystery trips” once you’re pulling live diagnostics.

- IEC 61131-3 programming – Feels familiar if you’ve used Siemens or Rockwell systems. Typically takes maintenance crews under two days to get productive with it.

No-Surprises Technical Reality Check

| Spec | Details |

|---|---|

| Brand/Model | HIMA F3417A |

| HS Code | 8537.10.9000 (Programmable controllers) |

| Power Requirements | 24V DC ±15%, 2.5A max – runs fine on standard plant UPS systems |

| Dimensions & Weight | 250mm H × 150mm W × 120mm D / 1.8kg – fits standard 19″ cabinets |

| Operating Temperature | -20°C to +60°C – survived Alberta winters in outdoor skids last winter |

| Signal I/O Types | Digital inputs (24V DC), relay outputs, HART-enabled analog – handles most field devices |

| Communication | Ethernet/IP, Modbus TCP – talks to SCADA without custom gateways |

| Installation | DIN rail mounted – no special brackets needed |

Where It Earns Its Keep

You’ll spot these in the guts of high-stakes operations: chemical reactors needing fail-safe temperature control, offshore platforms monitoring gas detection, or power plants managing turbine trips. A refinery in Texas recently shared how it prevented a hydrogen leak by catching valve position drift during a routine self-test – the kind of quiet win that doesn’t make headlines but keeps insurance premiums sane.

Procurement Teams Care About These Bits

It’s not flashy, but the compatibility with legacy HIMA systems saves serious integration headaches. One plant manager told me they avoided $80k in gateway costs by keeping their old I/O modules. Firmware updates are painless too – push them over the network during shift changes. Honestly, the real value shows up in year three when competitors’ controllers start needing recalibration every six months.

Installation & Maintenance Reality

Mount it on standard DIN rails in climate-controlled cabinets – no need for fancy cooling if you leave 50mm clearance on sides. Avoid cramming it next to VFDs; EMI from drives caused nuisance trips at one paper mill I visited. For maintenance: annual calibration checks (takes about 3 hours), quick dust-off with compressed air, and schedule firmware updates during planned outages. Skip the lockout/tagout procedure at your peril – seen two near-misses from rushed maintenance.

Certifications That Actually Matter

CE, UL 61010-1, IEC 61508 SIL 3 certified – no “self-declared” nonsense here. RoHS compliant since 2019 models. Warranty covers parts and labor for 365 days, though it typically sails past decade-long service lives in non-corrosive environments. One offshore rig’s unit just hit 14 years with only routine card swaps.

Reviews

There are no reviews yet.