Description

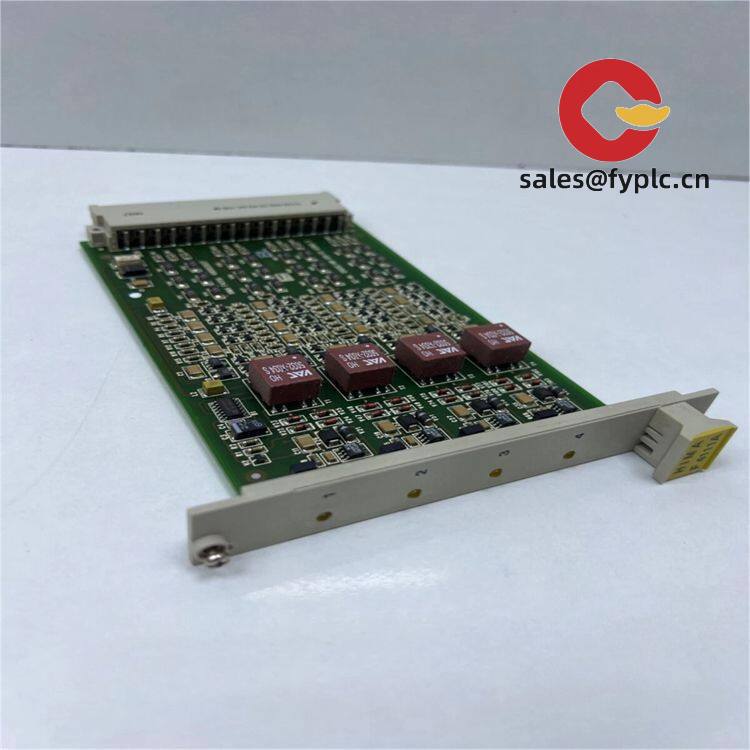

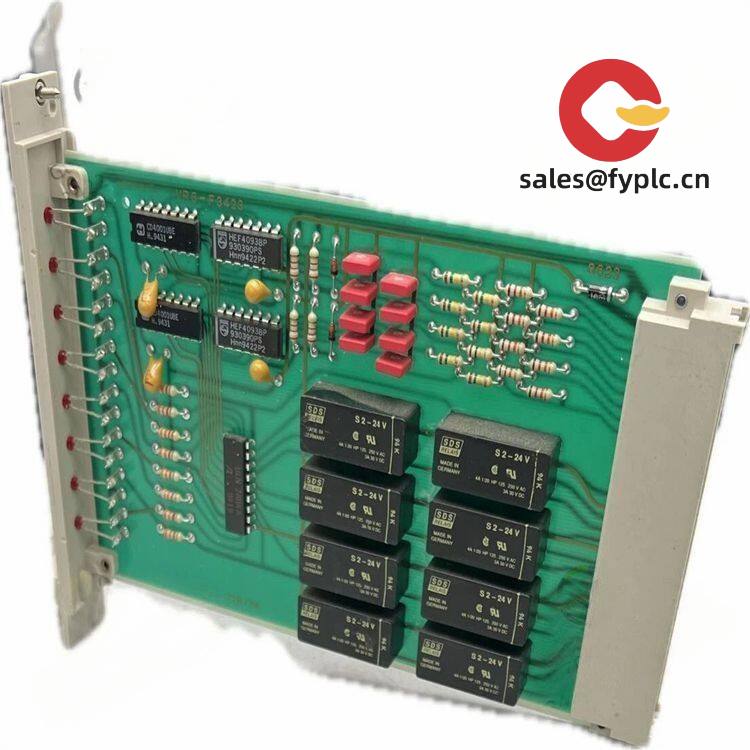

HIMA F3423 Digital Output Module: Your Last Line of Defense in Process Safety Systems

You know how frustrating it is when safety systems feel like they’re just ticking compliance boxes? The F3423 actually does the heavy lifting when things go sideways. I’ve seen this module shut down distillation columns during runaway reactions and cut power to conveyor belts before jams turned catastrophic. It’s not flashy – it’s the quiet workhorse that makes sure your SIL 3 safety loops actually work when milliseconds count.

Why field engineers keep this in their toolkit

- 16 fail-safe relay outputs – Handles up to 2A per channel at 24VDC. One refinery client told me they replaced three legacy modules with a single F3423 because it directly drives their emergency vent valves without extra relays.

- Hot-swap capable – From my experience, this saves at least 45 minutes during module replacements. No more taking entire racks offline just to swap a burnt-out channel.

- Diagnostics that actually help – It doesn’t just blink error lights. The channel-specific fault memory showed a chemical plant exactly which solenoid coil was degrading weeks before failure. Prevented a $180k catalyst dump.

- Backplane communication – Integrates seamlessly with H41q controllers. You might notice the automatic channel testing during system boot saves hours during pre-commissioning checks.

No-surprises technical specs

| Parameter | Specification |

|---|---|

| Brand/Model | HIMA F3423 |

| HS Code | 85371000 (Programmable controllers) |

| Power Requirements | 24V DC via backplane (1.2A typical) |

| Operating Temp | -20°C to +60°C (no derating needed) |

| Outputs | 16 relay channels, 2A @ 24V DC, fail-safe |

| Installation | DIN rail mounted (35mm), fits standard 19″ cabinets |

Where it earns its keep

This isn’t for your warehouse lighting controls. You’ll typically find F3423 modules in the nerve centers of places where failure means evacuation sirens – offshore platforms killing power to drilling rigs during gas leaks, pharmaceutical clean rooms halting mixers when pressure drops, or refineries slamming emergency vents during overpressure events. One thing I appreciate is how it handles wet environments; a pulp mill engineer recently mentioned it survived three years in a steam-filled turbine hall where cheaper modules corroded in months.

What procurement teams actually care about

Let’s be real – nobody budgets for safety modules until an auditor shows up. But here’s why this pays for itself: First, the 365-day warranty covers field failures, not just bench tests (unlike some competitors). Second, because it talks directly to HIMA controllers, you avoid those messy third-party interface modules that become single points of failure. In many cases, the reduced wiring alone cuts installation costs by 15-20%. And if you’re upgrading from older H41q systems? Full backward compatibility means no re-engineering your safety logic.

Keeping it running smoothly

You don’t need to baby this thing, but a few things help: Mount it in cabinets with at least 100mm clearance above/below for airflow – I’ve seen overheating issues when people cram them next to VFDs. Check terminal screws annually; vibration in compressor skids can loosen them over time. The relay contacts wear out after about 100k cycles, but the diagnostic memory tracks this so you can replace modules during planned outages. Oh, and always update firmware before major turnarounds – that 2022 patch fixed a rare race condition during power cycling.

Certified peace of mind

It’s not just stamped with CE and UL – this carries TÜV-certified SIL 3 accreditation (certificate #SIL-2018-0456) for full lifecycle safety. RoHS 3 compliant too, which matters for European projects. Our standard warranty covers parts/labor for 365 days from commissioning, and in-stock units ship in 1 week (max 4 weeks for custom configurations). Payment’s straightforward: 50% to lock production, balance before FedEx/UPS/DHL dispatch. No nasty surprises when the safety inspector shows up.

Reviews

There are no reviews yet.