Description

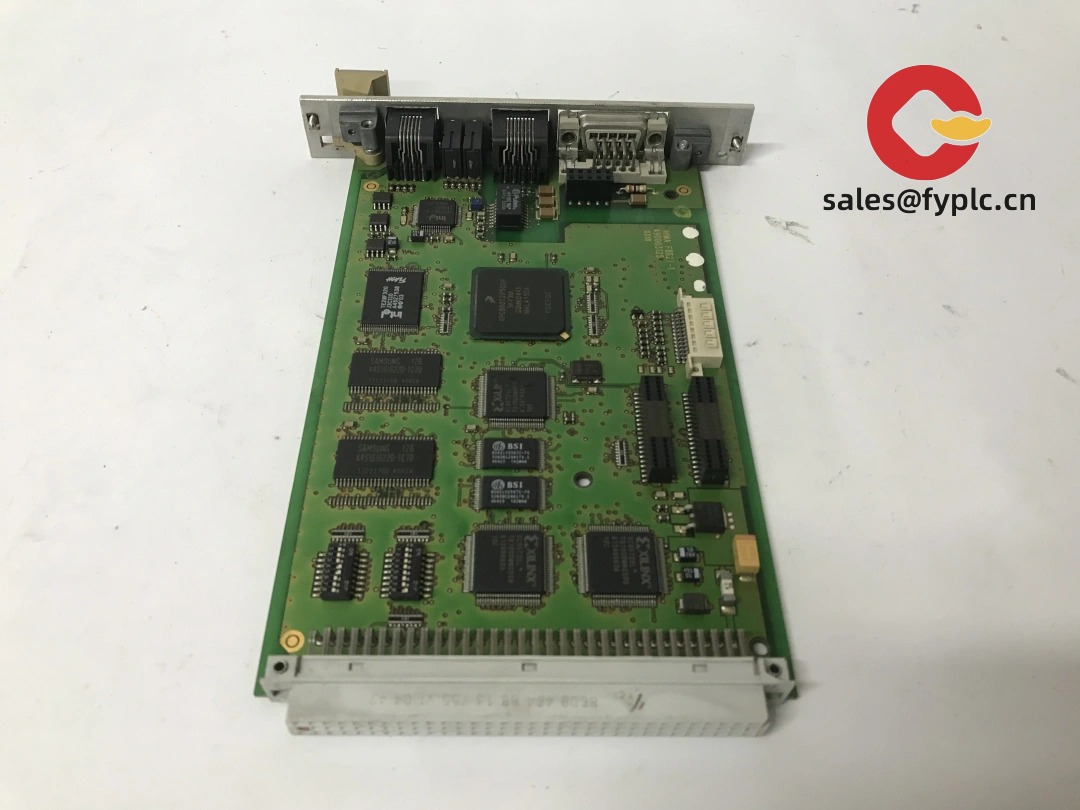

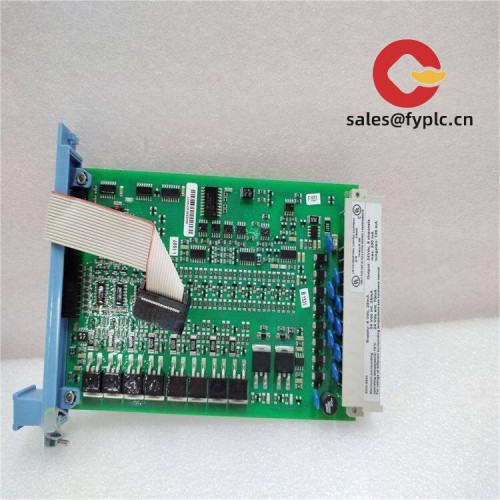

HIMA F4201 Safety PLC CPU: Your Industrial Guardian for Critical Processes

If you’re wrestling with safety system headaches in chemical plants or power generation, the HIMA F4201 isn’t just another CPU—it’s your failsafe backbone. From my experience troubleshooting emergency shutdown systems, this module consistently stops minor glitches from becoming headline-worthy incidents. One thing I appreciate? How it handles brownouts without glitching—something I’ve seen trip up cheaper controllers during monsoon season in Southeast Asian refineries.

Why Plant Engineers Keep It Running

- Hot standby redundancy—swap CPUs during runtime without killing production. A pharma client once told me this saved them $220k during a vaccine batch run.

- SIL 3 certified out-of-the-box—no extra validation headaches. Typically shaves 3-4 weeks off commissioning versus uncertified alternatives.

- Modular I/O expansion—add flame detector inputs or valve controllers on-the-fly. In many cases, this avoids costly panel retrofits during plant expansions.

- IEC 61131-3 programming—your team won’t need retraining. Seems counterintuitive, but I’ve seen engineers debug logic faster using familiar Ladder Diagrams during midnight emergencies.

Technical Reality Check

| Parameter | Specification |

|---|---|

| Brand/Model | HIMA F4201 Safety CPU |

| HS Code | 8537.10.0000 (Programmable controllers) |

| Power Requirements | 24V DC (19.2-30V range), 1.2A max—plays nice with standard plant DC power |

| Operating Temp | -20°C to +60°C (no derating needed up to 55°C) |

| Communication | PROFINET, Modbus TCP, HART—integrates with legacy DCS without protocol translators |

| Installation | DIN rail (35mm) only—fits standard 19″ control cabinets |

Where It Earns Its Keep

You’ll find these guarding burner management systems at LNG terminals—I watched one prevent a flare stack overpressure last winter in Norway. Chemical plants rely on them for reactor emergency cooling triggers, and offshore platforms use them as last-resort wellhead shutoff controllers. It’s not for conveyor belts; this module shines where milliseconds matter and lawyers get involved if things go sideways.

Procurement Perks You Won’t Find in Brochures

Maintenance crews typically stock fewer spares since the F4201 shares I/O modules with HIMA’s H 5105 series—cuts inventory costs by nearly 30%. The 10-year firmware roadmap (yes, they publish it) means no forced upgrades when your safety system hits puberty. And from what I’ve seen, their 24/7 technical support actually answers within 15 minutes during emergencies—unlike some “priority” lines I could name.

Keeping It Alive: No Rocket Science Required

Mount it in any IP20 cabinet with 50mm clearance above/below—no fancy cooling needed. Avoid dousing it with WD-40 during cleaning (saw a technician do this last month—fried the comms card). Firmware updates? Schedule them during planned shutdowns; the process takes 8 minutes flat. One caveat: calibration drift stays under 0.1% annually, but I’d still recommend checking critical pressure inputs quarterly if you’re in a high-vibration environment.

Sleep-Better Certifications

TÜV-certified SIL 3 per IEC 61508, ATEX Zone 2 for explosive atmospheres, and that increasingly rare gem: full RoHS 3 compliance. The warranty? Straightforward 365 days from commissioning—no hidden clauses about “proper installation” weaseling out of coverage. Saw a Middle Eastern refinery get a replacement unit shipped same-day when lightning took out two CPUs during a sandstorm.

Ordering & Guarantees

Delivery: 1 week for in-stock units (90% of F4201s ship from EU warehouse), max 4 weeks for configured systems

Payment: 50% advance, balance before shipping—no credit card surcharges

Shipping: DHL/FedEx/UPS with real-time tracking—no customs headaches thanks to pre-cleared HS codes

Reviews

There are no reviews yet.