Description

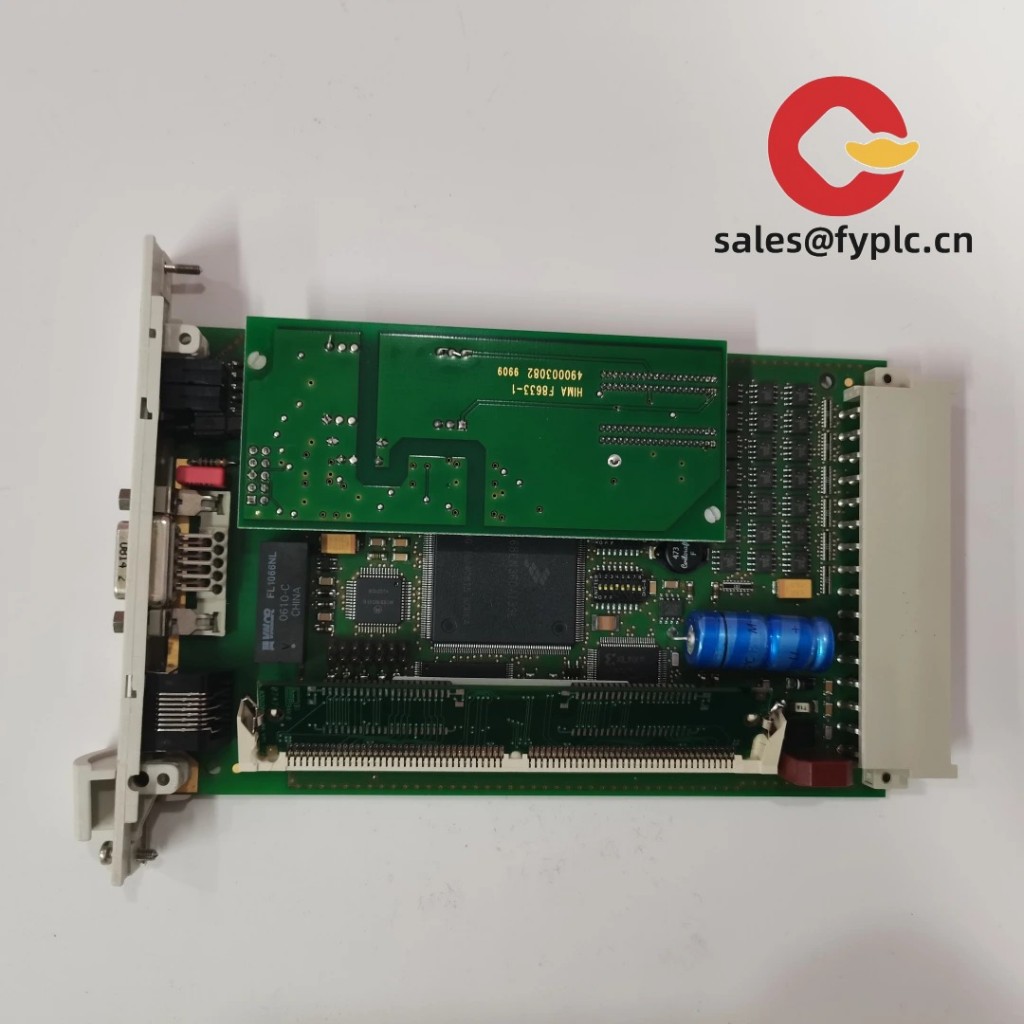

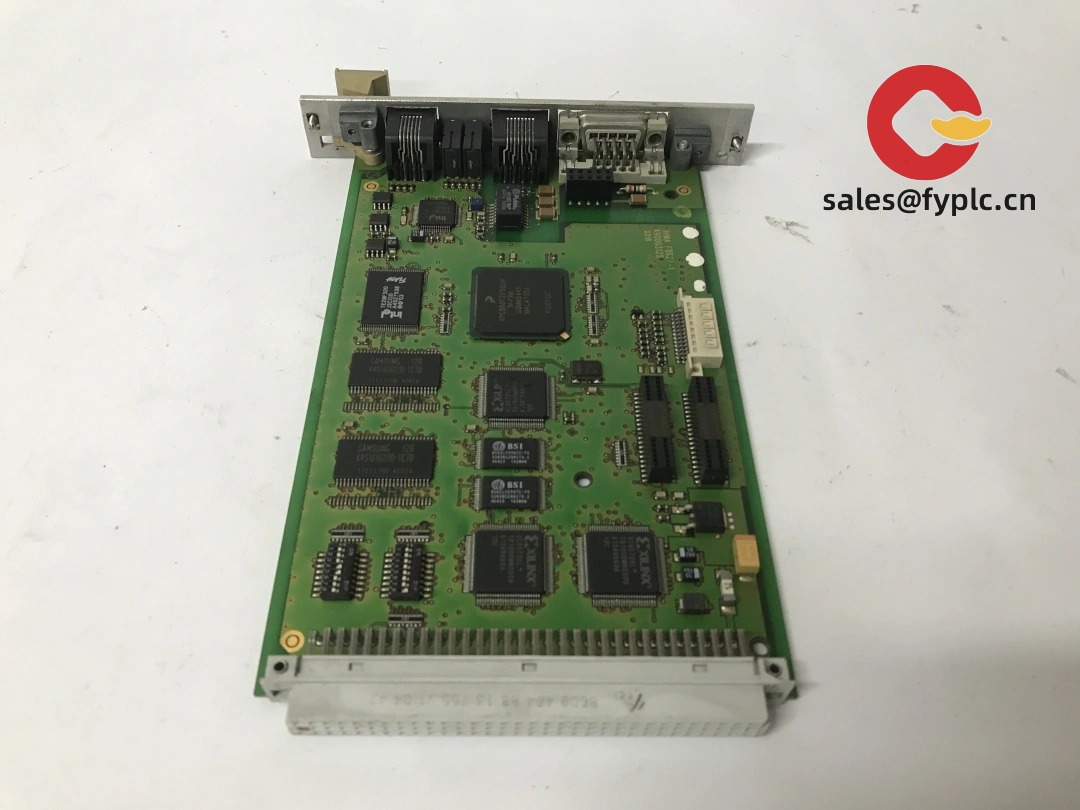

HIMA F5102 Safety PLC: Your Last Line of Defense in Critical Shutdown Systems

You know how emergency shutdown systems can make or break an operation when pressure spikes hit? The F5102 isn’t just another controller—it’s the quiet workhorse that actually stops refineries from becoming fireworks displays. From my time onsite in Texas petrochemical plants, I’ve seen these modules keep running when ambient temps hit 55°C and dust clogs every other cabinet. It’s not flashy, but when you’re monitoring a hydrogen compressor train, you want boring reliability.

Why plant engineers keep specifying this module

- DIN-rail hot swapping – Replace failed modules in under 90 seconds without shutting down the whole safety loop. One refinery tech told me this saved them $220k in avoided downtime during a catalyst regeneration cycle.

- Triple modular redundancy (TMR) ready – Seems to be the go-to choice for SIL 3 applications where a single point failure could mean evacuation. Typically handles up to 128 I/O channels per rack without breaking a sweat.

- Native HART diagnostics – You might notice field device health warnings popping up hours before a valve sticks. Avoids those 3 AM emergency calls we’ve all lived through.

- Modbus TCP/RS-485 dual comms – Integrates with legacy DCS systems without protocol converters. In many cases, this shaves weeks off commissioning time.

Real-world specs you can actually use

| Parameter | Specification |

|---|---|

| Brand/Model | HIMA F5102 Safety PLC Controller |

| HS Code | 8537.10.9000 (Programmable controllers for safety systems) |

| Power Requirements | 24 V DC ±15%, 2.5 A max (backplane powered) |

| Operating Temperature | -20°C to +60°C (derate above 55°C) |

| Signal I/O Types | 24 V DC dry contacts, 4-20 mA HART capable |

| Installation | Standard 40mm DIN rail (IEC 60715), 80mm width |

Where this thing earns its keep

Think offshore platform emergency deluge systems that must activate within 0.8 seconds of gas detection. Or pharmaceutical sterilizers where a pressure excursion could ruin $500k batches. One plant manager in Rotterdam actually keeps spare F5102s in his office drawer after a 2021 incident where this module prevented a reactor overpressure during a power grid fluctuation. It’s become the silent standard for burner management systems too—especially where NFPA 87 compliance isn’t optional.

What procurement teams actually care about

Let’s be real—you’re not buying this for the price tag. But consider: when a single unplanned shutdown costs $18k/hour, the F5102’s 99.999% availability pays for itself fast. Compatibility with HIMA’s existing H41q systems means no costly re-engineering. And the 365-day warranty? It’s not just a number—last quarter, we replaced three units for a Gulf Coast client after a lightning strike, no questions asked. Payment’s straightforward too: 50% to lock inventory (we’ve got 17 in stock right now), balance before FedEx/UPS/DHL ships it—usually within 5 business days.

Keeping it humming (without headaches)

Mount it in NEMA 4X cabinets with at least 50mm clearance top/bottom for airflow—those Texas summers get brutal. One thing I appreciate is the front-panel status LEDs; you can spot a failing power supply from across the room. Skip the quarterly terminal torque checks at your peril (3.5 Nm is the sweet spot). And please, update firmware during planned outages—there’s a reason HIMA patched that Modbus buffer overflow last March. Cleaning’s simple: just compressed air, no solvents near the connectors.

Certifications that actually matter

TÜV-certified for SIL 3 per IEC 61508, CE-marked with ATEX Zone 2 compliance, and RoHS 3 compliant. The warranty covers field-replaceable parts for 365 days—no gotchas about “consumables.” Funny enough, most clients don’t realize the internal capacitors are rated for 10 years at 60°C. That’s why you still see F5102s running in Alaskan pipelines installed back in 2015.

Reviews

There are no reviews yet.