Description

HIMA F6217 984621702 Analog Safety Input PLC Module

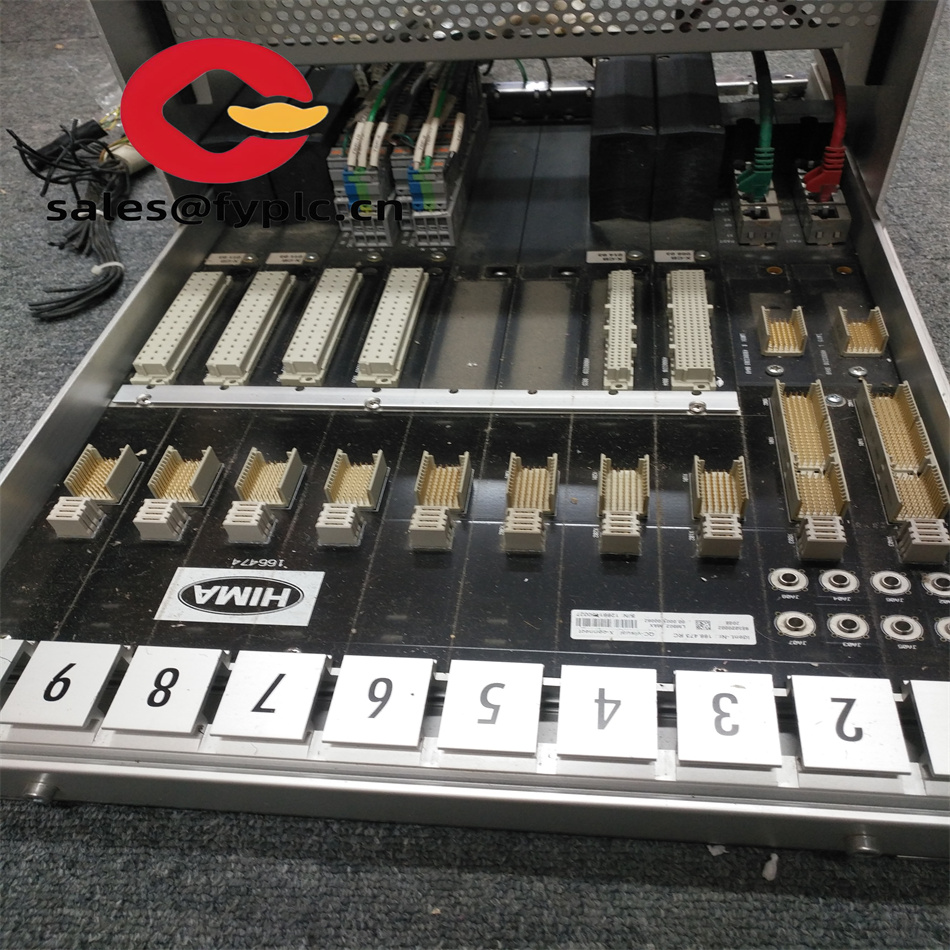

In the demanding landscape of industrial safety – critical systems, the HIMA F6217 984621702 emerges as a cutting – edge and indispensable component. This advanced safety – related I/O module is meticulously crafted to enhance the reliability and functionality of safety – instrumented systems (SIS), playing a pivotal role in safeguarding people, equipment, and the environment across diverse industries. Engineered to meet the most stringent safety standards, the HIMA F6217 984621702 is designed to integrate seamlessly into complex industrial control architectures, providing precise and real – time monitoring and control capabilities.

The HIMA F6217 984621702 serves as the crucial link between field devices, such as sensors and actuators, and the safety controller within an SIS. In industries like oil and gas, chemical processing, and power generation, where the consequences of a safety failure can be catastrophic, this module ensures that safety – critical signals are accurately transmitted and processed. Its high – performance design enables it to handle a wide range of input and output requirements, making it a versatile solution for various safety – related applications. Whether it’s detecting abnormal process conditions or triggering emergency shutdowns, the HIMA F6217 984621702 is up to the task, providing peace of mind to operators and stakeholders alike.

|

Label

|

Specification

|

|

Model Number

|

F6217 984621702

|

|

Brand

|

HIMA

|

|

Type

|

Safety – related I/O Module

|

|

Input Voltage

|

24 V DC

|

|

Operating Temp

|

-25°C to 65°C

|

|

Communication Method

|

PROFIBUS, Ethernet

|

|

Mounting

|

DIN Rail

|

|

Weight

|

Approximately 0.6 kg

|

|

Certifications

|

SIL 3 (IEC 61508), TÜV – certified

|

|

Dimensions

|

100mm x 120mm x 35mm

|

|

IP Rating

|

IP20

|

|

Protocols Supported

|

PROFIsafe, Modbus TCP

|

The HIMA F6217 984621702 offers a host of functional strengths and design advantages that set it apart in the industrial safety market. Its exceptional signal processing capabilities ensure accurate and reliable data acquisition from a variety of field sensors. The module’s high – speed response time allows for immediate action when safety – critical events occur, minimizing the potential for damage and disruption. Built with rugged materials, it can withstand harsh industrial environments, including electrical interference, vibrations, and temperature fluctuations, ensuring consistent performance over time.

Interoperability is a key feature of the HIMA F6217 984621702. It supports multiple communication protocols, enabling seamless integration with a wide range of safety controllers and other devices within an SIS. This compatibility simplifies system design and expansion, allowing for easy addition of new field devices as needed. The module’s redundant design further enhances its reliability, reducing the risk of single – point failures. Operators benefit from its user – friendly configuration interface, which makes it easy to set up and customize the module to meet specific safety requirements. This intuitive design not only saves time during installation but also reduces the potential for human error, ensuring the overall safety and efficiency of the system.

The HIMA F6217 984621702 finds extensive application in numerous industrial use cases, delivering significant value in terms of safety and operational efficiency. In oil refineries, it monitors critical parameters such as pressure, temperature, and flow rates in pipelines and storage tanks. When abnormal conditions are detected, the module quickly relays the information to the safety controller, which can then initiate appropriate safety actions, such as shutting down pumps or closing valves, to prevent leaks or explosions.

In chemical plants, the

HIMA F6217 984621702 plays a vital role in ensuring the safe handling of hazardous materials. It controls the operation of valves, pumps, and other equipment involved in chemical reactions, and in the event of a safety breach, it can immediately isolate the affected area to protect plant personnel and the environment. In power generation facilities, the module safeguards the operation of turbines, generators, and electrical grids by monitoring key parameters and triggering protective measures when necessary, helping to maintain the stability of the power supply and prevent blackouts.

When considering compatible and related models, the HIMA F6218 offers additional I/O channels, making it suitable for larger and more complex safety – instrumented systems that require handling of a greater number of signals. The HIMA F6117 is a more compact alternative, ideal for applications where space is limited but reliable safety – related I/O functionality is still essential. The HIMA F6317 stands out with its enhanced communication capabilities, enabling faster and more reliable data transfer within the SIS. The HIMA F6417 offers advanced diagnostic features, allowing for more precise identification of faults in the field devices connected to the module. The HIMA F6517 is designed with improved power management, reducing energy consumption while maintaining high – performance operation.

Installing the

HIMA F6217 984621702 requires careful attention to detail. When mounting it on a DIN rail, ensure that it is securely fastened to prevent any movement that could disrupt connections. Proper grounding is essential to protect the module from electrical surges and ensure stable operation. When connecting communication cables, follow the manufacturer’s guidelines to ensure reliable data transmission. Additionally, make sure to correctly wire the input and output connections to the appropriate field devices, as any incorrect connections could lead to inaccurate data acquisition or improper operation of the safety – instrumented system.

For long – term operation, regular maintenance of the

HIMA F6217 984621702 is crucial. Periodically check the module for any signs of physical damage, such as cracks or loose connections. Monitor the communication status to ensure that data is being transmitted accurately and without interruptions. Keep an eye on the module’s power consumption and temperature, as abnormal values could indicate potential issues. Update the module’s firmware as recommended by the manufacturer to benefit from the latest security patches, performance improvements, and new features. By following these maintenance practices, you can ensure that the

HIMA F6217 984621702 continues to provide reliable and effective safety – related I/O functionality throughout its service life.

HIMA stands firmly behind the quality and reliability of the HIMA F6217 984621702, as evidenced by its comprehensive warranty and support coverage. The manufacturer offers a generous warranty period, which reflects their confidence in the product’s durability and performance. In case of any issues, customers can rely on HIMA’s global support network. Technical experts are readily available to provide assistance, whether it’s through online resources, phone support, or on – site visits if necessary. Extensive documentation, including user manuals, installation guides, and troubleshooting tips, is also provided to help users make the most of the HIMA F6217 984621702. With such robust support, industries can invest in this safety – related I/O module with the assurance that they will receive long – term reliability and excellent customer service, ensuring the continued safety and smooth operation of their industrial processes.

For more information, please click below to learn more:

Reviews

There are no reviews yet.