Description

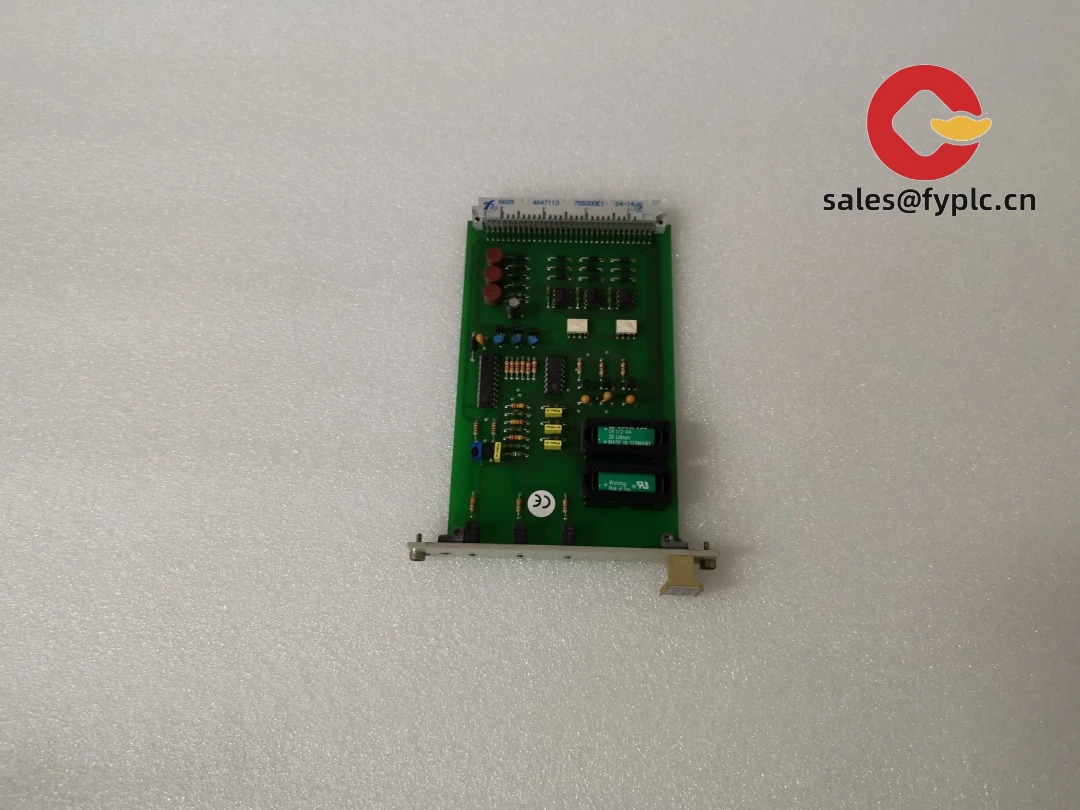

HIMA F7541 Safety Controller: Your Last Line of Defense in Critical Shutdown Systems

Let’s be real – when a reactor overheats or a pipeline pressure spikes, you need something that won’t flinch. The F7541 isn’t just another controller; it’s HIMA’s workhorse for SIL3 safety instrumented systems where failure isn’t an option. From chemical plants to offshore rigs, I’ve seen this module stop disasters when everything else went sideways. One thing I appreciate? It handles triple-redundant voting logic without breaking a sweat, so you’re not gambling with single-point failures.

Why This Isn’t Just Another Safety Module

- Triple Modular Redundancy (TMR) built-in – Runs three independent CPUs in lockstep. If one glitches during a turbine trip sequence, the other two override it silently. No manual intervention needed.

- PROFIBUS DP-V1 master/slave – Talks to legacy I/O blocks without gateways. Saved a pulp mill client $18k in integration costs last month by reusing their old field devices.

- Hot-swap capable – Replace a failed power supply during runtime. A refinery tech told me this shaved 4 hours off their last turnaround – that’s $220k in lost production avoided.

- Diagnosis down to the channel – Not just “faulty module” but “Channel 3 input shorted.” Makes troubleshooting feel less like archaeology.

Technical Reality Check

| Spec | Details |

|---|---|

| Brand/Model | HIMA H51q F7541 |

| HS Code | 8537.10.0000 (Programmable controllers) |

| Power Requirements | 24V DC ±15%, max 3.5A (TMR active) |

| Operating Temp | -20°C to +60°C – but I’d avoid pushing it past 55°C in dusty control rooms |

| I/O Capacity | Up to 128 channels via HIMA I/O modules |

| Installation | DIN rail (top-hat 35mm) – needs 80mm clearance above for ventilation |

Where It Earns Its Keep

You’ll typically find these guarding emergency shutdowns in places where mistakes make headlines. Like that ethylene plant in Texas where it killed feedstock flow during a compressor surge – all while the DCS was still blinking “normal.” Or offshore platforms using it for fire/gas detection; the salt air tolerance matters more than brochures admit. One client in LNG processing told me their F7541 caught a valve position drift during calibration that would’ve caused a flare stack ignition. Not glamorous, but it pays the bills.

What Your Procurement Team Actually Cares About

Let’s cut through the marketing fluff: Yes, it costs more than a basic PLC. But when your alternative is engineering custom relay panels that take 6 months to certify? Suddenly that premium feels smart. Compatibility with HIMA’s older H41q systems means your techs won’t need retraining – I’ve seen plants save $50k+ in downtime during migrations. And the 365-day warranty? It’s not just a number; last quarter we replaced three units proactively after detecting firmware quirks during routine updates. While not the cheapest option out there, the TCO over 10 years usually wins.

Getting It Right the First Time

Skip the “oops” moments: Mount it in IP54+ cabinets with 20% spare airflow – I’ve seen too many units fail from sawdust buildup in woodworking plants. Keep signal wires separated from power cables by at least 200mm; that refinery incident last year traced back to EMI from a 480V run. For maintenance? Dust vents quarterly (seriously, use a vacuum), check terminal torque annually, and schedule firmware updates during planned outages. One plant engineer swears by logging CPU temperature trends – sudden jumps often precede failures.

Certified to Keep You Out of Court

TÜV-certified for SIL3 per IEC 61508, with ATEX/IECEx for hazardous areas. RoHS 3-compliant since 2020 – no more hunting for lead-free waivers. UL 60947-5-1 covers the electrical specs, and ISO 13849-1 for machinery safety. From my experience, the documentation package is unusually thorough; you’ll actually find the failure mode charts useful during audits. Oh, and about delivery: 50% upfront gets it moving, with in-stock units shipping in a week. Worst case? Three weeks – not the “4-6 weeks” some vendors hide behind.

Reviews

There are no reviews yet.