Description

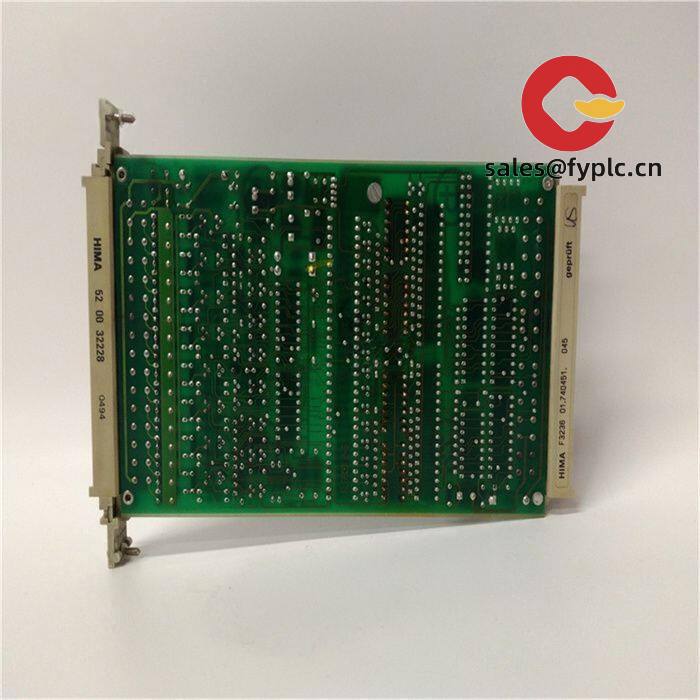

HIMA F8620/11 High‑Efficiency Central Processing Unit for Safety Controllers

The HIMA F8620/11 is a central processing unit module designed for HIMA safety systems—typically found in HIQuad-based architectures (such as H41q/H51q families). From my experience, plants choose the F8620/11 when they need dependable CPU performance, deterministic cycle times, and straightforward integration with existing HIMA racks and I/O. You might notice that it’s built for continuous operation in demanding environments where shutdowns are costly—BMS, ESD, and Fire & Gas frequently come up in the same sentence with this CPU.

Order Placement Process and Guarantees

- Warranty: 365 days from delivery

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment terms: 50% advance payment; full payment prior to delivery

- Express delivery options: FedEx, UPS, DHL

Key Features

- Safety‑grade processing: Engineered for use in safety instrumented systems; typically deployed up to SIL3 when used in approved HIMA system configurations.

- Deterministic cycle execution: Stable scan times help maintain predictable loop behavior, which is critical during trips and permissive logic.

- Rack‑backplane integration: Interfaces directly with the HIMA system backplane, coordinating I/O and communication modules without extra gateways.

- Designed for continuous operation: Industrial‑grade components and watchdog mechanisms to sustain 24/7 runtime in harsh conditions.

- Engineering tool compatibility: Works with HIMA engineering environments used on HIQuad systems, supporting typical programming, diagnostics, and download workflows.

- Migration‑friendly: In many cases, it maintains compatibility with existing HIMA racks and I/O, helping reduce retrofit risk and downtime.

Technical Specifications

| Brand / Model | HIMA F8620/11 Central Processing Unit |

| HS Code | 8537.10 (Boards/panels for electric control, industrial use) |

| Power Requirements | 24 VDC via system backplane (typical, supplied from the rack power module) |

| Dimensions & Weight | Rack module, Eurocard form factor (6U style); front insertable; field‑replaceable |

| Operating Temperature | Typically 0 to +60 °C (check specific system manual for limits) |

| Signal I/O Types | No direct field I/O; interfaces with HIMA I/O modules over the system backplane |

| Communication Interfaces | System backplane bus; controller communications provided via dedicated comm modules; engineering access typically Ethernet‑based |

| Installation Method | Installed in a compatible HIMA rack/chassis; secured with front panel fasteners; wiring through rack backplane |

Application Fields

Typical deployments include functional safety applications where deterministic logic and high availability matter:

- Emergency Shutdown (ESD) logic solvers in upstream and downstream O&G

- Boiler/Burner Management Systems (BMS) in power generation and utilities

- Fire & Gas detection and shutdown interlocks in chemical and petrochemical plants

- Turbomachinery protection and permissives where fast, repeatable response is required

Advantages & Value

- Reliability that reduces unplanned outages: Watchdog supervision and proven field history in safety systems.

- Compatibility with existing HIMA racks and I/O: Often allows staged upgrades without a full system replacement.

- Lower lifecycle costs: Standardized spares, stable firmware branches, and simplified maintenance procedures in many cases.

- Technical support and know‑how: Broad ecosystem of trained engineers and TÜV‑recognized methodologies for validation.

One thing I appreciate is how maintenance teams can replace the CPU during a planned window without rewiring I/O, which typically shortens turnaround. A maintenance lead recently mentioned their first download and switchover took under an hour because the rack and I/O stayed intact.

Installation & Maintenance

- Panel/cabinet: Install in a rated control cabinet with adequate ventilation; keep ambient within specified temperature/humidity range.

- Grounding and shielding: Bond cabinet earth properly; route shielded field cables and follow HIMA EMC practices.

- Power: Use clean 24 VDC supply modules recommended for the HIMA rack. Redundant supplies are advisable for safety applications.

- Wiring: All field wiring lands on I/O modules; the CPU uses the system backplane only—avoid inserting/removing modules under load unless the system specifically allows it.

- Maintenance: Schedule firmware checks during outages, back up logic and configuration before updates, and inspect front‑panel connectors for wear or contamination. Light dust cleaning improves long‑term reliability.

- Validation: After replacement or firmware change, perform functional proof tests per your SIS procedures and record the as‑built revision.

Quality & Certifications

- CE compliance (EMC and safety directives)

- IEC 61508 safety certification up to SIL3 when used in approved system architectures (TÜV assessed)

- RoHS conformant materials

- Manufactured under ISO 9001 quality management

- Standard warranty: 365 days

Related Components (for a Typical Setup)

- HIMA rack/chassis for HIQuad series (for mechanical mounting and backplane power)

- HIMA I/O modules (digital/analog input/output depending on the loop design)

- Communication modules (e.g., Ethernet or fieldbus, as required by the DCS/PLC interface)

- Redundant power supply modules for 24 VDC

If you’re modernizing an existing HIQuad cabinet or planning spares coverage, the HIMA F8620/11 seems to be a safe, low‑risk choice. Share your rack type and firmware baseline, and we can match a compatible CPU and comm stack without surprises.

Reviews

There are no reviews yet.