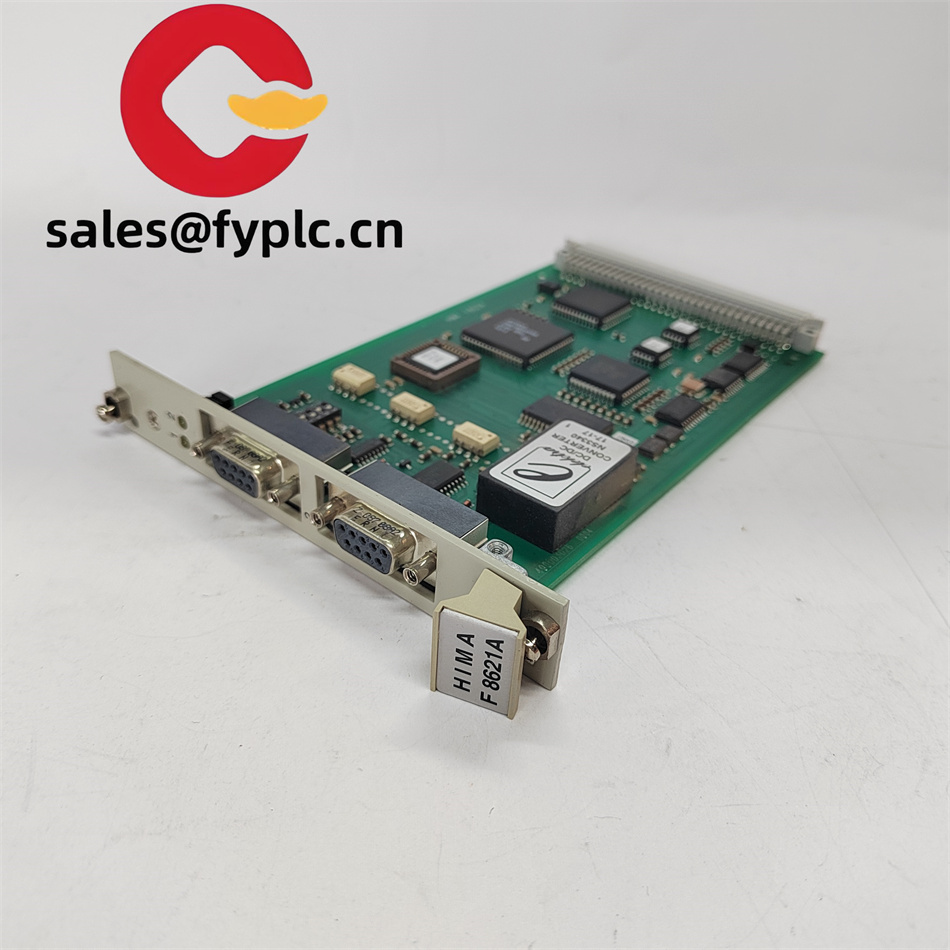

HIMA F8621A Digital All Around King Safety Relay

| Model Number | F8621A |

| Brand | HIMA |

| Type | Safety Controller (TMR Architecture) |

Tel: +86 17350880093

Whatsapp: 17350880093

E-mail : sales@fyplc.com

Zhangzhou Fengyun Electrical Equipment Co.LTD

Categories: HIMA

Need help?

Email: sales@fyplc.cn

Tel/WhatsApp: +86 173 5088 0093

Description

HIMA F8621A Digital All Around King Safety Relay

HIMA F8621A: High-Reliability Safety Controller for Critical Industrial Applications

In industries where safety is non-negotiable—such as oil & gas, chemical processing, and power generation—the HIMA F8621A stands as a cornerstone safety controller. Engineered by HIMA Paul Hildebrandt GmbH, a global leader in safety-critical systems, the F8621A is part of the renowned H41q series, designed to meet the most stringent functional safety standards (IEC 61508, IEC 61511) for safety instrumented systems (SIS). This triple modular redundant (TMR) controller ensures fail-safe operation in high-risk environments, providing deterministic control and diagnostics to prevent catastrophic failures and protect personnel, assets, and the environment.

The F8621A serves as the brain of safety instrumented systems, executing emergency shutdown (ESD), fire & gas detection, and critical process control logic. Its TMR architecture—with three independent processing channels that vote on outputs—ensures high availability and fault tolerance, making it ideal for applications requiring SIL 3 certification. Whether deployed in a refinery’s emergency shutdown system or a pharmaceutical plant’s safety-critical batch processes, the F8621A delivers unparalleled reliability and precision.

| Label | Specification |

|---|---|

| Model Number | F8621A |

| Brand | HIMA |

| Type | Safety Controller (TMR Architecture) |

| Safety Integrity Level | SIL 3 (IEC 61508), CL 3 (IEC 61511) |

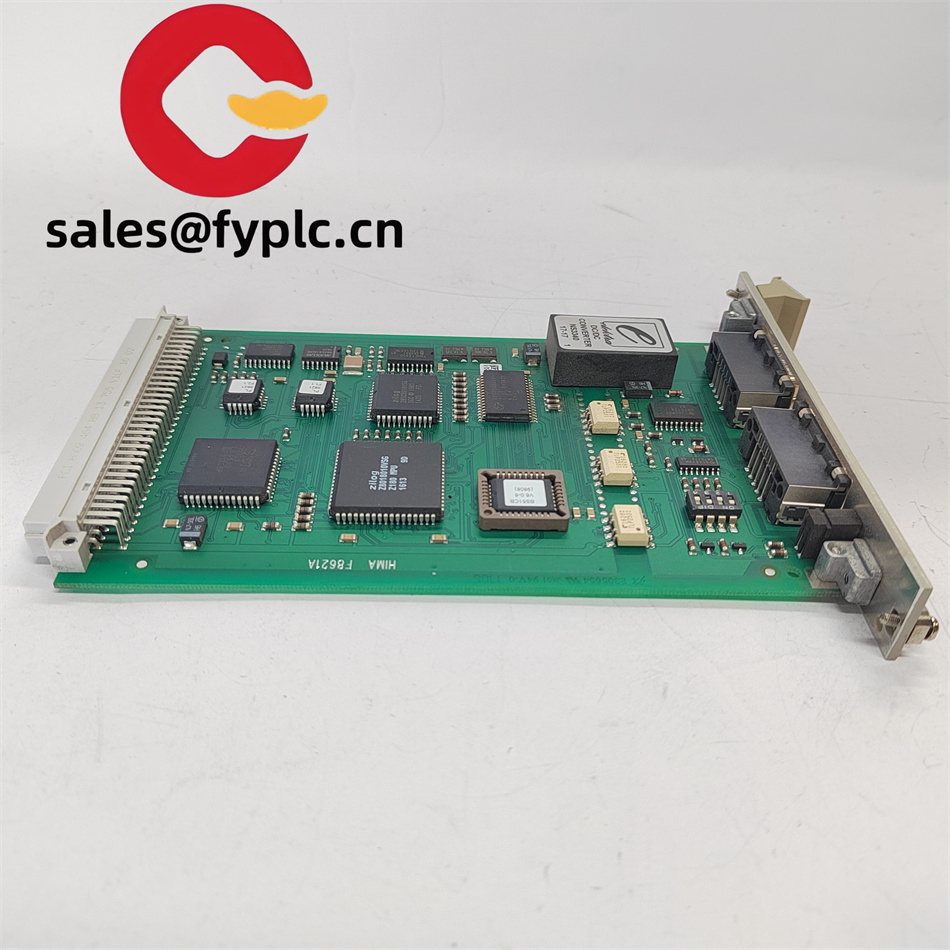

| Architecture | Triple Modular Redundant (TMR) with hardware/software voting |

| Processing Speed | 100 μs per logic step (typical) |

| Communication Interfaces | Ethernet (10/100 Mbps), PROFIBUS DP, Serial (RS-232/485) |

| Operating Temperature | -20°C to +60°C |

| Power Supply | 24 VDC (redundant inputs) |

| Dimensions | 250 mm x 100 mm x 180 mm (rack-mountable) |

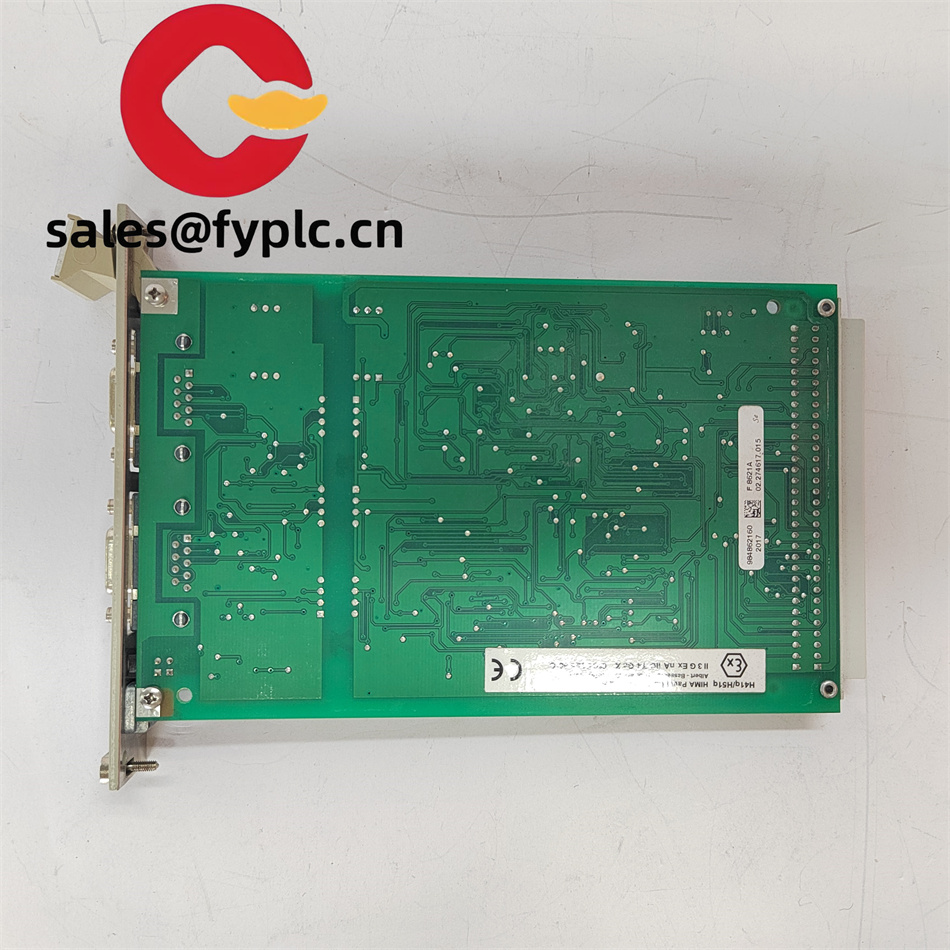

| Certifications | IEC 61508, IEC 61511, ATEX, IECEx, FM, CSA |

| Input/Output Capacity | Supports up to 1,000 I/O points via expansion modules |

| Fault Diagnostics | >99% self-diagnostic coverage (IEC 61508) |

Functional Strengths & Design Advantages

The HIMA F8621A is engineered for safety and resilience. Its TMR architecture provides intrinsic fault tolerance: if one channel detects a fault, the system continues operating on the remaining two, ensuring no single point of failure. This design, combined with hot-swappable modules, allows maintenance without shutting down the safety system—a critical feature for 24/7 operations.

The controller’s high-speed processing ensures rapid response to safety events, with logic execution speeds in the microsecond range. This is vital for applications like gas leak detection, where delays could have severe consequences. The F8621A also supports online configuration changes, enabling engineers to update safety logic without interrupting operations, reducing downtime during modifications.

Security is baked into the design, with features like encrypted communication protocols and access control to prevent unauthorized changes to safety logic. The controller’s diagnostic coverage exceeds 99%, continuously monitoring hardware and software for faults and reporting anomalies via built-in LEDs or integrated HMIs.

Industrial Use Cases & Value Scenarios

In oil & gas production, the F8621A manages emergency shutdown systems, ensuring rapid response to leaks, overpressure, or fire incidents. Its TMR architecture ensures that even in the event of a channel failure, the safety system remains operational, preventing environmental disasters and protecting personnel. In chemical manufacturing, the controller oversees safety-critical reactions, shutting down processes if parameters exceed safe limits, thus avoiding explosions or toxic releases.

For power generation, the F8621A safeguards turbine systems by monitoring vibration, temperature, and pressure sensors, initiating trips if anomalies are detected. In all these scenarios, the controller addresses the core challenge of balancing safety with operational continuity, delivering:

- Regulatory Compliance: Meets global safety standards, ensuring audit readiness.

- Cost Efficiency: Reduces unplanned downtime through predictive diagnostics and online maintenance.

- Scalability: Supports modular expansion, adapting to small-scale systems or large industrial complexes.

Compatible and Related Models

- HIMA F8650A – Advanced TMR controller with integrated Ethernet and enhanced processing power for complex SIS applications.

- HIMA F8627A – Simplified single-channel controller for SIL 2 applications, ideal for smaller-scale safety systems.

- HIMA F8152A – I/O module for analog inputs, compatible with the F8621A to expand sensor connectivity.

- HIMA F8153A – Relay output module for driving actuators in ESD systems.

- HIMA F8621B – Next-generation variant with improved cybersecurity features and faster communication protocols.

Setup & Service Guidance

Installation involves mounting the F8621A in a dedicated safety-rated control cabinet, ensuring proper ventilation and separation from non-safety equipment. Key setup steps include:

- Redundant Power: Connect two independent 24 VDC supplies to ensure power continuity.

- I/O Cabling: Use shielded, twisted-pair cables for analog signals and separate safety/non-safety wiring to avoid interference.

- Configuration: Program safety logic using HIMA’s HiDAC software, which supports IEC 61131-3 languages (Ladder Logic, ST, SFC).

For maintenance:

- Periodic Diagnostics: Use HiDAC to review self-diagnostic reports and identify potential faults (e.g., failing memory modules).

- Firmware Updates: Apply updates during scheduled outages to ensure compatibility with new sensors or regulatory requirements.

- Functional Safety Tests: Conduct annual proof tests as per IEC 61511, using HIMA’s built-in test modes to validate controller performance.

- Spare Parts Management: Maintain a stock of critical components (e.g., power supplies, I/O modules) for rapid replacement.

Warranty & Support Coverage

HIMA guarantees the F8621A with a 3-year warranty, reflecting confidence in its rugged design and compliance with safety standards. Customers gain access to HIMA’s global safety expertise, including 24/7 technical support, on-site commissioning, and customized training programs. Comprehensive documentation—such as safety requirement specifications (SRS) and fault tree analysis (FTA) reports—is provided to assist with system validation and regulatory audits.

For more information, please click below to learn more:

Be the first to review “HIMA F8621A Digital All Around King Safety Relay” Cancel reply

Reviews

There are no reviews yet.