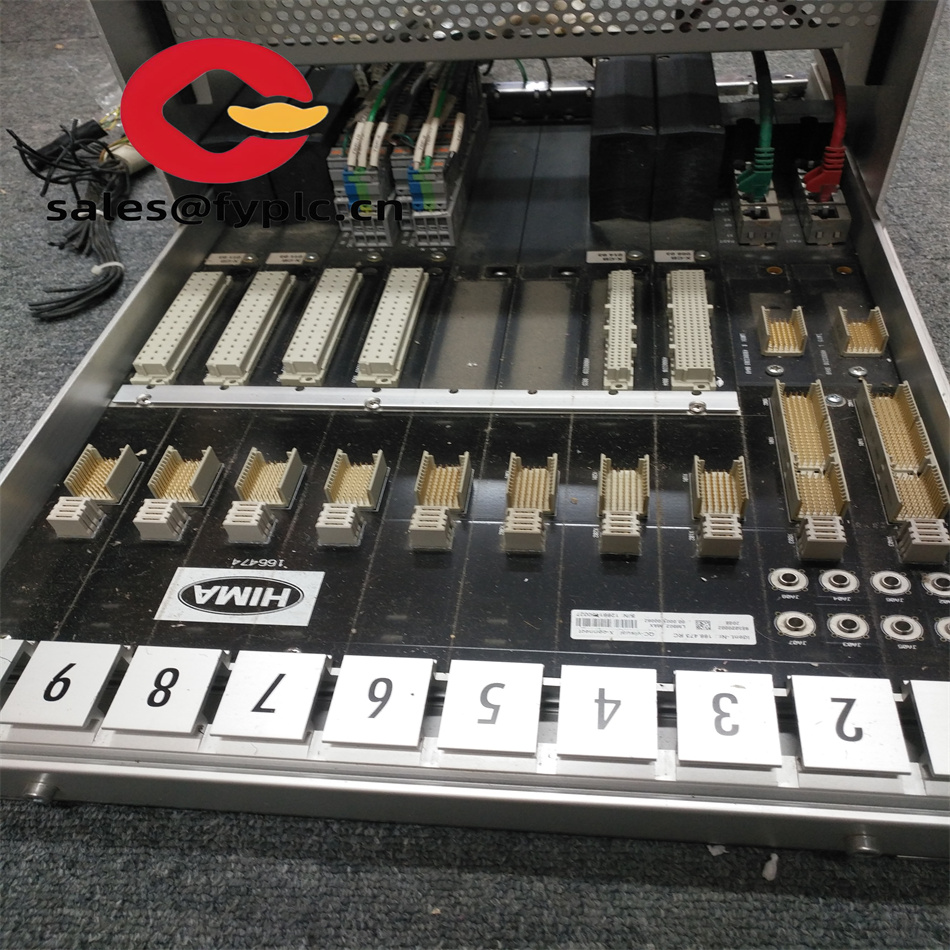

In the intricate web of industrial safety – critical operations, the HIMA LM002_MAX 985020002 stands as a paragon of innovation and reliability. This high – performance logic module is engineered to be the nerve center of safety – instrumented systems (SIS), meticulously designed to safeguard people, protect equipment, and preserve the environment across diverse industrial landscapes. Whether it’s the volatile environments of oil and gas refineries, the complex processes of chemical plants, or the high – stakes operations in power generation facilities, the HIMA LM002_MAX 985020002 is built to handle the most demanding safety – related tasks with precision and speed.

At its core, the HIMA LM002_MAX 985020002 is designed to integrate seamlessly into existing industrial control architectures. It acts as the crucial link that processes data from a multitude of sensors, analyzes safety – critical information in real – time, and triggers appropriate responses to prevent hazardous situations from escalating. By ensuring the accurate and timely execution of safety functions, this module plays an irreplaceable role in maintaining the integrity and continuity of industrial operations.

The HIMA LM002_MAX 985020002 is brimming with functional strengths and design advantages that set it apart in the industrial safety market. Its powerful processing capabilities allow it to handle complex safety algorithms and a high volume of data with ease, ensuring minimal latency in decision – making and response times. This means that in the event of an emerging safety threat, the module can quickly analyze the situation and initiate the necessary safety actions, such as shutting down equipment or activating emergency alarms, in a matter of milliseconds.

The module’s resilience is a standout feature. Built with rugged materials and advanced engineering, it can withstand harsh industrial conditions, including electrical interference, mechanical vibrations, and extreme temperature fluctuations. This durability ensures consistent performance over the long term, reducing the risk of unexpected failures that could compromise safety. Moreover, the HIMA LM002_MAX 985020002 offers excellent interoperability, supporting multiple communication protocols that enable seamless integration with a wide range of field devices, controllers, and other components within an SIS. This flexibility makes it easy to expand and upgrade safety systems as industrial requirements evolve.

The HIMA LM002_MAX 985020002 finds extensive application in numerous industrial scenarios, delivering significant value in terms of safety and operational efficiency. In oil and gas production, it continuously monitors parameters like pressure, temperature, and gas levels in pipelines and storage tanks. When abnormal conditions are detected, the module instantly processes the information and triggers safety measures to prevent leaks, explosions, or other catastrophic events, protecting both the facility and the surrounding environment.

In chemical plants, where the handling of hazardous materials requires strict safety protocols, the HIMA LM002_MAX 985020002 oversees chemical reactions, valve operations, and material transfers. It ensures that all processes adhere to safety standards, and in case of any deviations, it promptly initiates corrective actions to avoid accidents and safeguard the well – being of plant workers. In power generation, the module plays a vital role in maintaining the stability of electrical grids, monitoring the performance of generators and turbines, and preventing blackouts by quickly responding to any potential safety issues.

When considering compatible and related models, the HIMA LM003_MAX offers enhanced processing power and additional input/output capabilities, making it suitable for larger and more complex SIS setups. The HIMA LM001_MIN is a more compact and cost – effective alternative, ideal for smaller industrial applications where space is limited but reliable safety logic is still required. The HIMA LM004_PRO stands out with its advanced diagnostic features, enabling more precise identification of faults within the safety system. The HIMA LM005_EX is designed for explosive environments, offering enhanced protection and safety features to meet the unique requirements of hazardous locations. The HIMA LM006_GRID is tailored for power grid – related safety applications, with specialized functions for monitoring and controlling electrical systems.

Installing the HIMA LM002_MAX 985020002 requires careful attention to detail. When mounting it on a DIN rail, ensure it is properly aligned and securely fastened to prevent any movement that could disrupt connections. Adequate grounding is essential to protect the module from electrical surges and ensure stable operation. When connecting communication cables, follow the manufacturer’s guidelines precisely to guarantee reliable data transmission. Additionally, make sure to correctly configure the module’s settings according to the specific safety requirements of your industrial application.

For long – term operation, regular maintenance of the HIMA LM002_MAX 985020002 is crucial. Periodically inspect the module for any signs of physical damage, loose connections, or abnormal heat generation. Monitor its communication status to ensure data is being transmitted accurately and without interruptions. Keep the module’s firmware up – to – date as per the manufacturer’s recommendations, as firmware updates often include important security patches, performance improvements, and new features. By following these maintenance practices, you can ensure that the HIMA LM002_MAX 985020002 continues to operate reliably and effectively, providing unwavering safety support to your industrial processes.

Reviews

There are no reviews yet.