Description

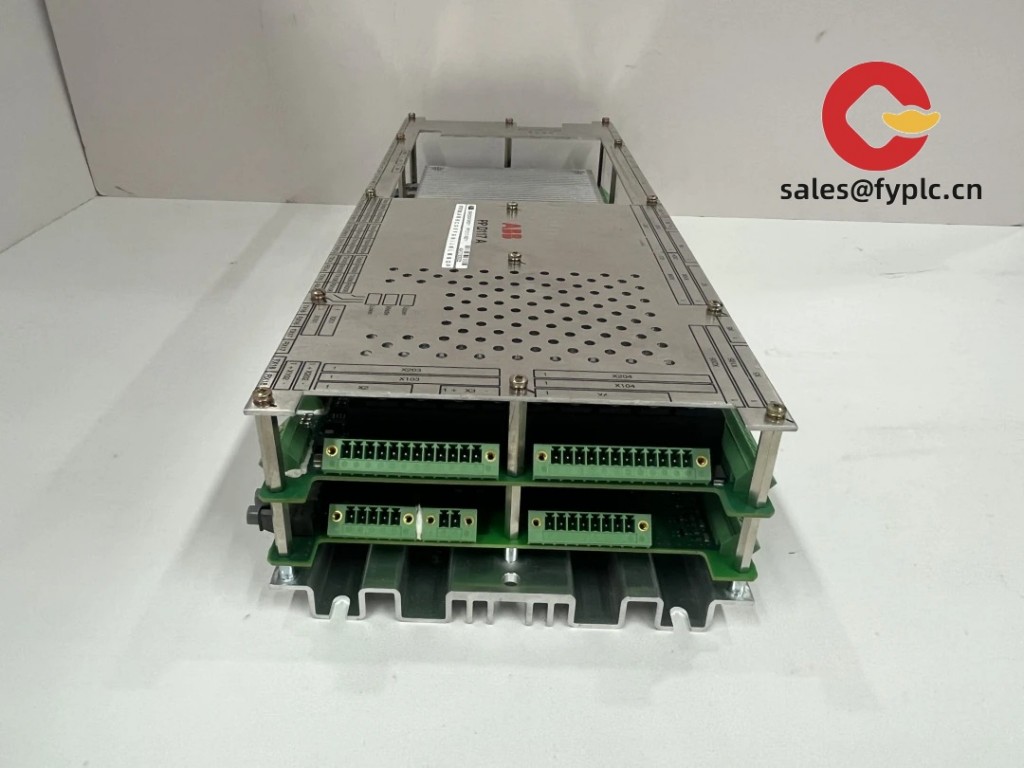

HIMA X-AO 16 01 Analog Output Module – Reliable 16‑channel analog outputs for safety controllers

Despite the “DO” wording you might have seen elsewhere, the model X-AO 16 01 (often written as X-AO1601) is an Analog Output module in HIMA’s X-series. It’s designed to provide stable, precise analog signals from a HIMax/HIQuad X safety controller to the field—think valve positioners, VFD speed references, and control elements that expect 4–20 mA. From my experience, plants choose this module when they need consistent analog performance inside a SIL-rated architecture, without juggling third‑party signal conditioners.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- 16 analog output channels: Suitable for driving multiple control valves, actuators, or speed references from one slot.

- Typical 0/4–20 mA ranges: Matches standard process instrumentation; easy drop‑in for brownfield upgrades.

- Safety integration with HIMax/HIQuad X: Designed for use in HIMA safety systems targeting SIL 3 architectures.

- Channel diagnostics: You might notice quicker loop troubleshooting thanks to per‑channel fault and status feedback in the engineering tool.

- Backplane communication: No external bus adapter required; configuration handled via the controller and SILworX.

- Redundancy-ready designs: In many cases, used in systems with redundant power and controller paths to minimize downtime.

- Hot serviceability: Plants typically report fast replacement without major process interruption when procedures are followed.

Technical Specifications

| Brand / Model | HIMA X-AO 16 01 (X-AO1601) |

| HS Code | 853890 (Parts for electrical control equipment) |

| Power Requirements | Backplane powered from system 24 VDC supply (via HIMax/X-series rack) |

| Signal Output Types | 16x analog outputs; typical 0/4–20 mA sourcing for process control loops |

| Communication Interfaces | Internal backplane interface to HIMax/HIQuad X controller; configured via SILworX |

| Operating Temperature | Typically 0…+60 °C (use datasheet limits for final design) |

| Installation Method | Plugs into X-series rack slot; field wiring via front terminal connectors |

| Dimensions & Weight | Single-slot X-series module; under 0.5 kg |

Application Fields

This module fits process safety and high-availability control where analog actuation matters. Typical scenarios:

- Oil & gas: driving valve positioners for emergency shutdown and blowdown control.

- Chemicals & petrochemicals: dosing pumps, reactor temperature control via 4–20 mA outputs.

- Power & utilities: turbine/governor reference signals and boiler controls in safety-related loops.

- Pharma & food: CIP/SIP temperature and flow regulation with validated safety logic.

- Metals & mining: analog drive references where interlocks and safety logic run on HIMax.

Advantages & Value

- System compatibility: Purpose-built for HIMA safety platforms, which typically cuts integration risk and commissioning time.

- Lifecycle confidence: Stable firmware and diagnostics reduce nuisance trips and help maintenance teams focus on real issues.

- Scalable I/O density: 16 channels per slot helps keep cabinets compact and wiring tidy—useful in brownfield cabinets.

- Procurement simplicity: One vendor for controller, I/O, and tools; easier spares planning and support escalation.

- Total cost of ownership: In many cases, fewer external signal conditioners and less panel space translate to lower installed cost.

Installation & Maintenance

- Panel standards: Mount in a properly rated enclosure; allow ventilation around the rack and follow earthing best practices.

- Wiring: Use shielded twisted-pair for analog loops; land shields at a single approved ground point to avoid ground loops.

- Loop power: Most 4–20 mA devices will need external loop power; verify polarity and burden per channel.

- Safety procedures: De-energize or follow hot-swap procedures approved by your site and HIMA documentation before handling modules.

- Routine care: Periodic loop calibration, connector inspection/cleaning, and firmware updates via SILworX (when qualified) keep performance steady.

A maintenance lead at a Middle East refinery told us their swap time dropped “from hours to minutes” after standardizing on X-series analog I/O—mostly because diagnostics pointed straight to the failing loop.

Quality & Certifications

- Functional safety: Designed for use in SIL 3 architectures (IEC 61508) within HIMA systems.

- CE marking: Typically compliant for EMC and LVD in industrial environments.

- RoHS: Conforms to RoHS directives in most cases.

- UL/CSA: Many X-series modules carry North American approvals; verify exact file for the module revision.

- Manufacturer warranty: 12 months (365 days).

One thing I appreciate is how straightforward the X-AO 16 01 is to drop into existing HIMA racks—minimal learning curve if your team already uses SILworX. If you’re replacing what was thought to be a “digital output” card, just flag that X-AO 16 01 is analog; for digital outputs the corresponding X-DO modules are the right match.

Reviews

There are no reviews yet.