Description

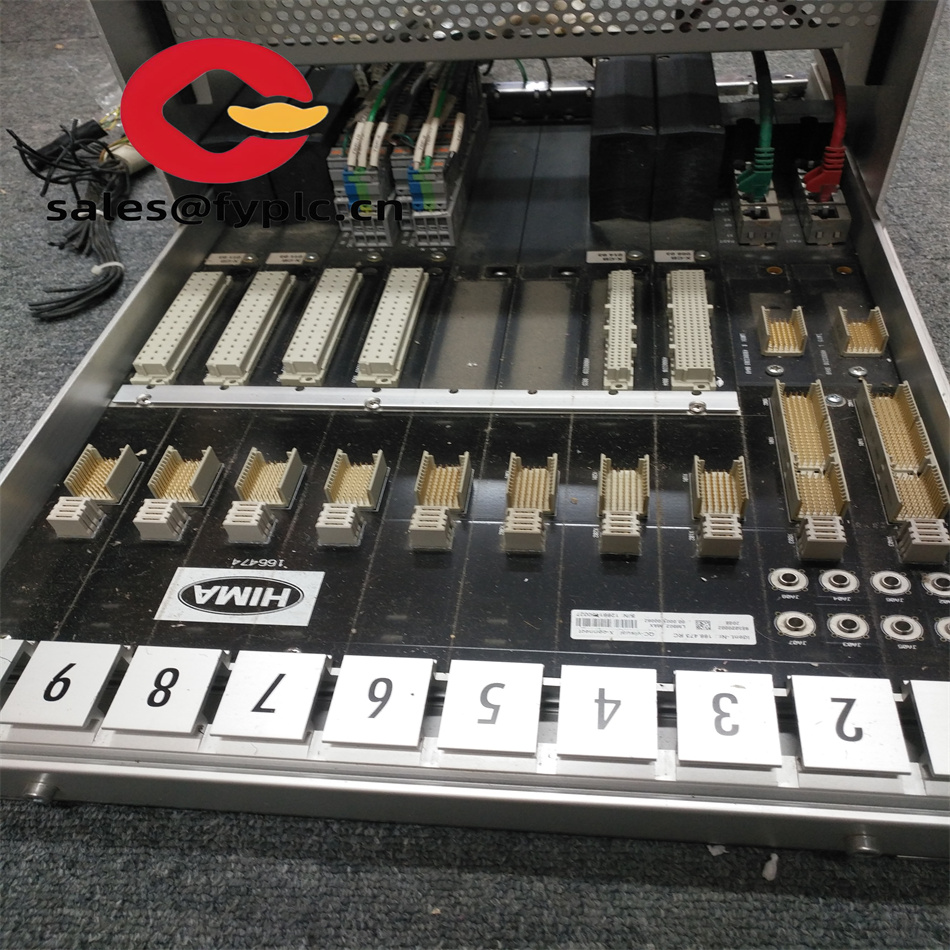

HIMA X-BLK01 632590802 Control Module Analog Power Supply

In the dynamic and safety – centric realm of industrial automation, the HIMA X-BLK01 632590802 emerges as a groundbreaking solution that redefines connectivity and functionality within safety – instrumented systems (SIS). This advanced interface module is meticulously engineered to serve as the essential bridge, enabling seamless communication between various components of an SIS, thereby enhancing the overall reliability and efficiency of industrial safety operations. Whether it’s the high – risk environments of petrochemical plants, the intricate processes in pharmaceutical manufacturing, or the large – scale power generation facilities, the HIMA X-BLK01 632590802 is designed to meet the diverse and demanding requirements of modern industrial safety setups.

At its essence, the HIMA X-BLK01 632590802 is crafted to integrate effortlessly into existing industrial control architectures. It acts as a communication hub, facilitating the transfer of critical safety – related data between sensors, actuators, logic controllers, and other elements of an SIS. By ensuring the accurate and timely transmission of information, this module plays a pivotal role in maintaining the integrity of safety processes, allowing for rapid detection of anomalies and prompt initiation of safety responses. This makes it an indispensable asset for industries where the protection of personnel, equipment, and the environment is of utmost importance.

|

Label

|

Specification

|

|

Model Number

|

X-BLK01 632590802

|

|

Brand

|

HIMA

|

|

Type

|

Interface Module

|

|

Input Voltage

|

24 V DC

|

|

Operating Temp

|

-25°C to 65°C

|

|

Communication Method

|

Ethernet, PROFIBUS, CANopen

|

|

Mounting

|

DIN Rail

|

|

Weight

|

Approximately 0.5 kg

|

|

Certifications

|

SIL 3 (IEC 61508), TÜV – certified

|

|

Dimensions

|

100mm x 80mm x 30mm

|

|

IP Rating

|

IP20

|

|

Protocols Supported

|

PROFIsafe, Modbus TCP, CANopen Safety

|

HIMA-X-BLK01-632590802-4

The HIMA X-BLK01 632590802 is packed with functional strengths and design advantages that distinguish it in the competitive industrial safety market. Its high – speed data transfer capabilities ensure that safety – critical information is transmitted instantaneously, minimizing latency and enabling real – time decision – making. This means that in the face of an emerging safety threat, the module can quickly relay data to the relevant components, allowing for immediate action to be taken, such as shutting down machinery or activating emergency alarms.

The module’s robust build quality is a testament to its resilience. Constructed with durable materials and advanced engineering techniques, it can withstand the harsh conditions typical of industrial environments, including electrical noise, mechanical vibrations, and extreme temperature variations. This durability ensures consistent performance over time, reducing the likelihood of unexpected failures that could compromise the safety of industrial operations. Interoperability is another key strength of the HIMA X-BLK01 632590802. With support for multiple communication protocols, it can seamlessly integrate with a wide array of devices and systems, regardless of their manufacturer or specific design. This flexibility makes it easy to incorporate the module into existing SIS setups or to expand and upgrade safety systems as industrial needs change.

The HIMA X-BLK01 632590802 finds extensive application across a multitude of industrial scenarios, delivering significant value in terms of safety and operational excellence. In petrochemical plants, it plays a crucial role in monitoring and controlling processes such as oil refining and chemical synthesis. By enabling seamless communication between sensors that detect parameters like pressure, temperature, and chemical composition, and the safety logic controllers, it ensures that any deviations from safe operating conditions are quickly identified and addressed. This helps prevent potentially catastrophic events such as chemical spills, fires, or explosions.

HIMA-X-BLK01-632590802-4

In pharmaceutical manufacturing, where precision and safety are non – negotiable, the HIMA X-BLK01 632590802 oversees the production processes, ensuring that equipment operates within safe parameters and that any issues are promptly resolved. It enables the smooth flow of data between various production stages, from ingredient mixing to packaging, ensuring product quality and the safety of workers handling potentially hazardous materials. In power generation facilities, the module is integral to maintaining the stability of the electrical grid. It facilitates communication between generators, transformers, and other critical components, allowing for real – time monitoring and control to prevent power outages and ensure a reliable supply of electricity.

When considering compatible and related models, the HIMA X-BLK02 offers enhanced communication bandwidth, making it suitable for larger and more data – intensive SIS setups. The HIMA X-BLK03 is a more compact variant, ideal for applications where space is at a premium but reliable connectivity is still essential. The HIMA X-BLK04 stands out with its advanced diagnostic features, enabling more precise identification of communication issues within the SIS. The HIMA X-BLK05 is designed with additional security features, providing an extra layer of protection for critical safety – related data transmission. The HIMA X-BLK06 offers improved power efficiency, reducing energy consumption while maintaining high – performance operation, which is beneficial for industries aiming to cut down on operational costs.

HIMA-X-BLK01-632590802-4

Installing the HIMA X-BLK01 632590802 requires careful attention to detail. When mounting it on a DIN rail, ensure that it is properly aligned and securely fastened to prevent any movement that could disrupt connections. Adequate grounding is essential to protect the module from electrical surges and ensure stable operation. When connecting communication cables, follow the manufacturer’s guidelines precisely to guarantee reliable data transmission. It’s also important to correctly configure the module’s communication settings according to the specific requirements of your industrial safety system, ensuring seamless integration with other components.

For long – term operation, regular maintenance of the HIMA X-BLK01 632590802 is key. Periodically inspect the module for any signs of physical damage, loose connections, or abnormal heat generation. Monitor its communication status to ensure data is being transmitted accurately and without interruptions. Keep the module’s firmware up – to – date as per the manufacturer’s recommendations, as firmware updates often include important security patches, performance improvements, and new features. By following these maintenance practices, you can ensure that the HIMA X-BLK01 632590802 continues to operate smoothly and effectively, providing reliable connectivity and support for your industrial safety processes.

HIMA-X-BLK01-632590802-4

HIMA stands firmly behind the quality and reliability of the HIMA X-BLK01 632590802, offering a comprehensive warranty and exceptional support coverage. The manufacturer’s generous warranty period reflects their confidence in the product’s durability and performance. In case of any issues, customers can rely on HIMA’s global network of technical experts, who are readily available to provide assistance through various channels, including online resources, phone support, and on – site visits when necessary. Extensive documentation, such as user manuals, installation guides, and troubleshooting handbooks, is also provided to help users maximize the module’s potential. With such robust support, industries can invest in the HIMA X-BLK01 632590802 with the assurance that they will receive long – term reliability and top – notch customer service, ensuring the continued safety and smooth operation of their critical industrial systems.

For more information, please click below to learn more:

Reviews

There are no reviews yet.