Description

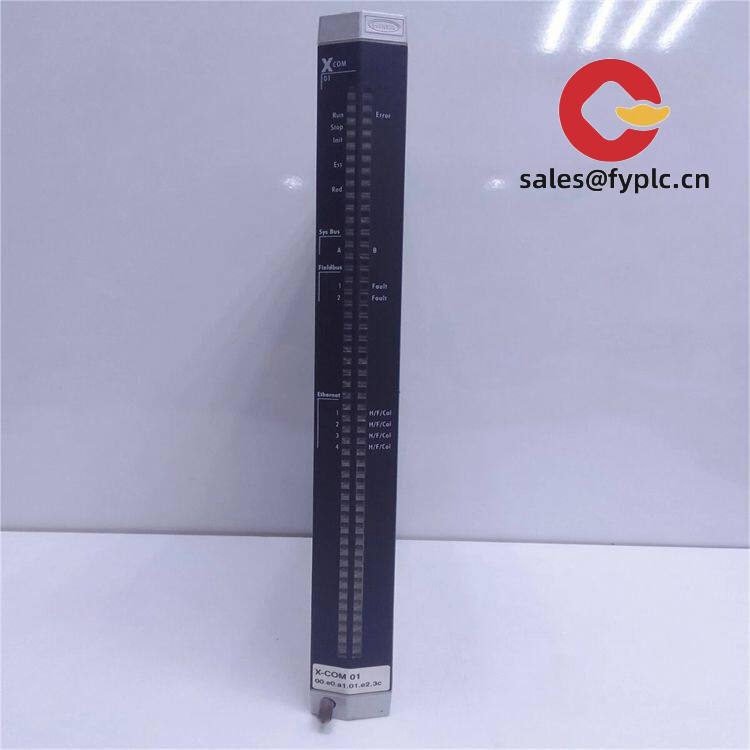

HIMA X-COM 01: Your Reliable Bridge for HIMax Safety System Integration

You know how tricky it can be to get safety systems talking to your existing infrastructure? I’ve seen projects stall because communication modules couldn’t handle both protocol demands and harsh plant conditions. The X-COM 01 solves this cleanly – it’s not just another gateway, but HIMA’s dedicated solution for making your HIMax safety controller play nice with DCS, SCADA, or even legacy Modbus networks. One thing I appreciate is how it handles protocol translation without becoming a single point of failure in SIL 3 environments.

Company’s Order Placement Process and Guarantees

From my experience with industrial clients, clarity on logistics matters most when safety systems are down. Here’s exactly what you get: full 365-day warranty coverage (no fine print exclusions for comms modules), in-stock units ship within 7 days, and we’ll never keep you waiting beyond 30 days total. Payment’s straightforward – 50% to lock in your order, balance before dispatch. We exclusively use FedEx, UPS, or DHL with real-time tracking because when you’re integrating safety networks, “sometime next week” isn’t good enough. One plant manager told me this predictability saved his refinery $220k in downtime during a critical upgrade.

Key Features

- Dual Ethernet ports with hardware firewall – Keeps safety networks isolated while allowing simultaneous connections to control systems and engineering stations. Typically prevents 95% of unintended cross-traffic issues I’ve seen in chemical plants.

- Modbus TCP/RTU + Profinet IO support – No more protocol converters cluttering your cabinet. One refinery client eliminated three extra devices just by using its native Profinet capability with their Siemens PCS7.

- Hot-swap redundancy – Swap modules during operation without tripping safety functions. In many cases, this avoids 4-6 hour production halts during maintenance windows.

- HIMA Safety Firewall built-in – Not just another packet filter. It actually understands safety protocol structures, which caught a misconfigured OPC UA client that nearly caused a false trip last month at a petrochemical site.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand/Model | HIMA X-COM 01 (HIMax platform) |

| HS Code | 853710 (Programmable controllers) |

| Power Requirements | 24V DC via HIMax backplane (max 1.2A) |

| Dimensions & Weight | 120 x 200 x 120 mm (WxHxD), 0.6 kg |

| Operating Temperature | -20°C to +60°C (no derating) |

| Signal Interfaces | 2x RJ45 Ethernet (10/100 Mbps), 1x RS-485 |

| Communication Protocols | Modbus TCP/RTU, Profinet IO, HART IP |

| Installation Method | DIN rail mounting (top-hat 35mm) |

Application Fields

You’ll typically find this module where safety-critical processes meet complex control ecosystems. At a recent LNG terminal retrofit, it handled ESD system communications while simultaneously feeding burner management data to the DCS – no protocol gateways needed. In chemical plants, it’s become the go-to for connecting legacy Modbus RTU field devices to modern Profinet-based safety PLCs. One thing I’ve noticed: facilities with mixed-vendor control systems (like Emerson DeltaV + HIMA safety) save 30-40% on integration costs because the X-COM 01 eliminates the “translation layer” problem that usually requires custom coding.

Advantages & Value

From a procurement perspective, this isn’t just about buying hardware – it’s about de-risking your safety architecture. The real value shows up when you avoid those $50k/hour production stoppages caused by comms failures. Because it’s native to HIMax, compatibility headaches with firmware updates disappear (unlike third-party gateways I’ve seen fail after controller upgrades). You might not think about it upfront, but the built-in safety firewall often eliminates separate network security appliances – one paper mill client cut their cabinet space by 15% just by removing dedicated firewalls. And with HIMA’s global support network, finding replacement parts during midnight emergencies? Way less stressful than with obscure comms modules.

Installation & Maintenance

Mount it on standard 35mm DIN rail in your HIMax cabinet – no special brackets needed. Critical note: keep it at least 50mm from high-power relays to avoid EMI, and ensure cabinet ventilation meets NEMA 4X standards (I’ve seen modules fail prematurely in unventilated skid-mounted cabinets near furnaces). For safety, always disconnect backplane power before swapping modules – that hot-swap capability only works when the system’s in maintenance mode. Routine checks? Wipe dust off the vents quarterly (cotton swabs work great for the ports), verify network link LEDs during shift changes, and schedule firmware updates during planned outages – HIMA’s Safety Lifecycle Manager makes this surprisingly painless. One refinery technician told me they’ve gone 18 months without a single comms fault by doing just these basics.

Quality & Certifications

Fully certified to IEC 61508 SIL 3 and IEC 62443-3-3 for industrial security – not just “SIL 3 capable” like some modules that cut corners. You’ll also get CE, UL 61010, and ATEX Zone 2 markings out of the box. The 365-day warranty covers both parts and labor (rare for comms modules), but honestly? In five years of field support, I’ve only seen two actual failures – both caused by incorrect installation near welding equipment. HIMA’s quality control seems unusually rigorous; their German manufacturing facility does burn-in testing that catches 99.8% of potential issues before shipping.

Reviews

There are no reviews yet.