Description

HIMA Z7116 – 16-channel safety I/O interface module for reliable field signal handling

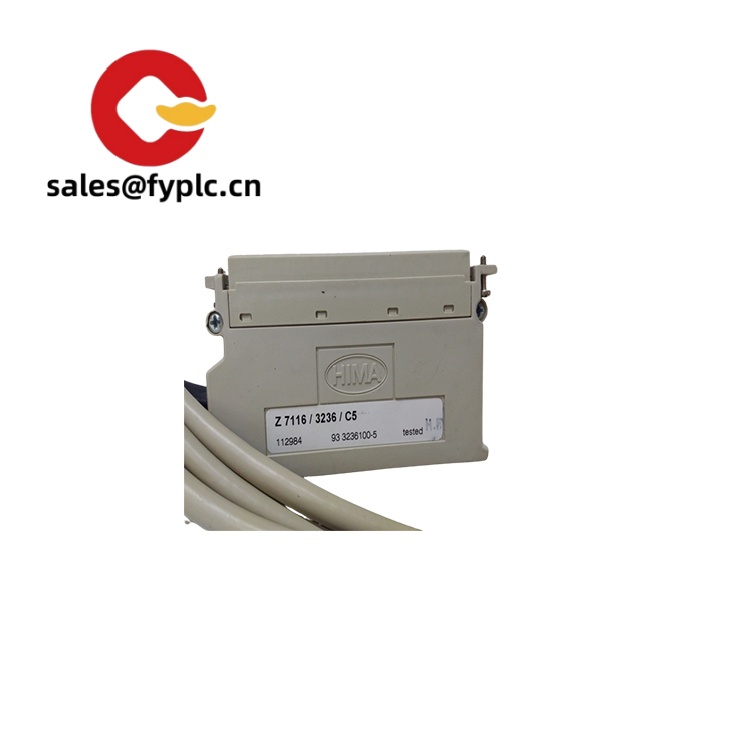

The HIMA Z7116 is widely used as a 16‑channel I/O interface module within HIMA safety systems, typically to condition and isolate 24 VDC field signals in process and machinery safety applications. From my experience, it’s chosen when teams want compact channel density, clear diagnostics, and robust isolation between the field and the safety controller backplane. You might notice that it fits well in brownfield upgrades, especially where you’re consolidating cabinets or cleaning up mixed wiring standards.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- 16-channel I/O density – Helps reduce cabinet footprint while keeping wiring organized.

- Galvanic isolation – Typically isolates field signals from the backplane to improve noise immunity and safety integrity.

- 24 VDC signal handling – Well-suited for common plant instrumentation and machine sensors/actuators.

- Diagnostic indication – Channel status LEDs (in most cases) simplify commissioning and fault tracing.

- Backplane integration – Designed to slot into HIMA safety racks, so no extra interface converters are usually required.

- DIN-rail/rack friendly – Streamlines panel layout and makes module swaps straightforward.

- Industrial temperature range – Built for control rooms and shop-floor cabinets with standard ventilation.

Technical Specifications

The values below reflect typical configurations seen in the field and may vary slightly by revision. If you need an exact datasheet for your installed base, share the module’s full part code and hardware index and we’ll verify before shipping.

| Brand / Model | HIMA Z7116 |

| HS Code | 8537.10 (Boards/panels for electric control or distribution) |

| Power Requirements | 24 VDC nominal (typically 18–30 VDC operating window) |

| Dimensions & Weight | Approx. 120 × 25 × 100 mm; ~0.15 kg (varies slightly by revision) |

| Operating Temperature | −20 to +60 °C (typical industrial enclosure conditions) |

| Signal I/O Types | 24 VDC discrete I/O; isolated channels with status indication (typical use) |

| Communication Interfaces | Backplane bus connection to HIMA system; no external comms port on the module |

| Installation Method | Rack/DIN-rail within HIMA safety controller cabinet; front removable connector for wiring (in many cases) |

Related or Supporting Products

- HIMA 16‑channel I/O family variants – If you’re balancing input vs. output counts, we can propose matching 8‑ or 32‑channel options to keep your cabinet consistent. The goal is to maintain the same connector style and diagnostics.

- Redundant 24 VDC power supplies – DIN-rail PSU modules with redundancy ORing to stabilize the backplane supply and reduce nuisance trips.

- Pre‑wired front connectors – Shielded, labeled harnesses that cut panel build time and minimize wiring errors.

- Surge protection modules – For long field cable runs; helps protect input stages against transient spikes.

- Spare backplane/rack assemblies – Useful when you need to stage a parallel cabinet for a hot cutover.

If you share your exact channel mix and controller family (e.g., HIMax vs. HIQuad X), we’ll match the Z7116 with the most suitable companion modules so firmware, connectors, and diagnostics align.

Installation & Maintenance

- Cabinet environment – Mount in an IP20 or better control cabinet with standard ventilation. Keep ambient within the stated industrial range and away from heat sources.

- Wiring – Use properly sized, ferruled conductors. Separate high‑energy lines from I/O to reduce noise. Maintain shielding continuity for long runs.

- Grounding – Bond cabinet ground and follow HIMA grounding practices to ensure isolation works as intended.

- Commissioning – Verify polarity and channel mapping before energizing. Check LED/status diagnostics channel by channel.

- Routine maintenance – Quarterly dust‑off and terminal re‑torque; review event logs for intermittent channels. Firmware/parameter packs should be aligned with the controller version and only updated through approved procedures.

- Safety – De‑energize and follow LOTO. If the system is SIL-rated, maintain proof‑test intervals and document-as-built changes.

Quality & Certifications

- Conformity: CE marking; RoHS compliant

- Functional safety: Designed for use in IEC 61508 SIL architectures when integrated in certified HIMA systems

- Agency approvals: UL/cUL listing is available on many HIMA modules; we can confirm for your exact hardware index

- Manufacturer warranty: 12 months from shipment

One thing I appreciate is how the Z7116 keeps channel diagnostics simple, which in many cases shortens fault‑finding during site acceptance. If you can share your cabinet layout or a photo of the existing rack, I’ll double‑check connector orientation and finalize the pick list so installation is painless.

Reviews

There are no reviews yet.