Description

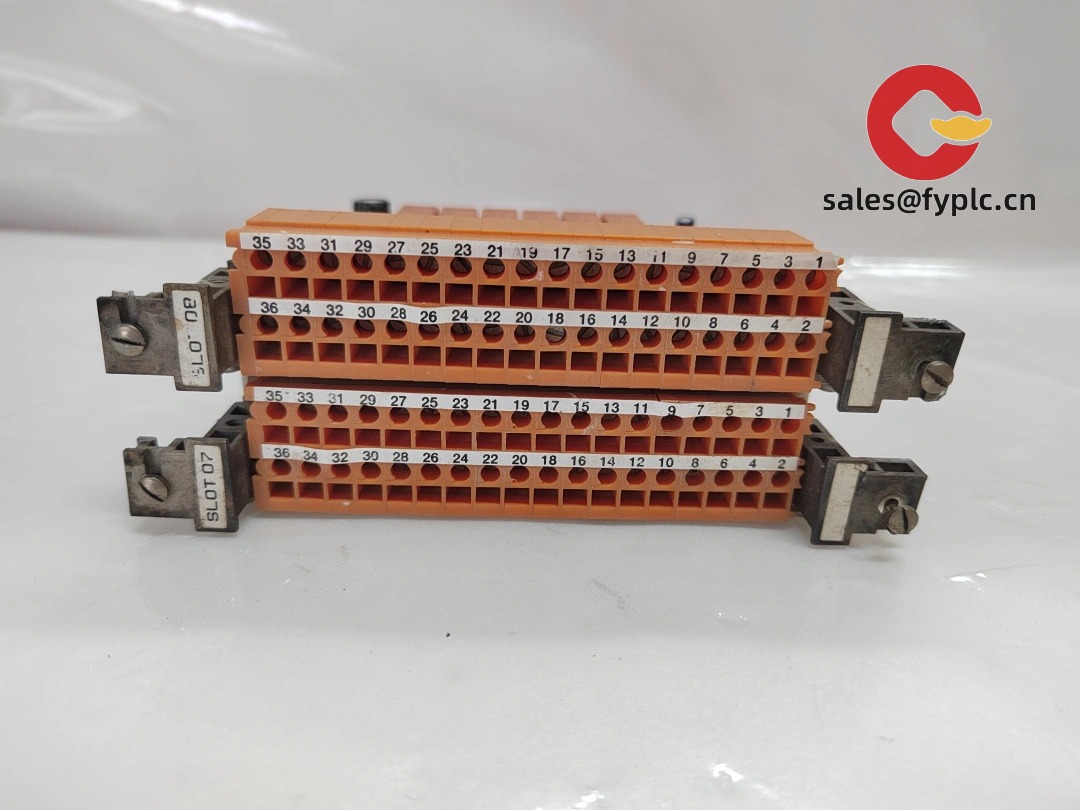

HONEYWELL 05074-A-012 / 0574-A-0131 – Pre-terminated cable/adapter set for clean, reliable DCS/ESD panel wiring

The HONEYWELL 05074-A-012 and 0574-A-0131 part numbers are commonly supplied together as an OEM-grade cable/adapter assembly for tying controller or I/O hardware to field termination points inside a control cabinet. One thing I appreciate is how a pre-engineered harness like this typically cuts wiring time, reduces cross-termination errors, and keeps loop checks moving during a tight outage window. From my experience, plants use this kit in Experion or legacy Honeywell cabinets when they want a straightforward, plug-and-go connection between modules and terminal strips without improvising in the field.

Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock; no more than one month at the latest

- Payment terms: 50% advance payment; full payment for delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- OEM-fit harnessing

– Pre-terminated connectors with defined pinouts help avoid wiring mistakes and rework. - Shielded, noise‑aware design

– Suited to typical cabinet EMC practices; helps keep low-level I/O signals clean next to power wiring. - Service-friendly labeling

– Clear tag points make loop checks and proof tests faster in most cases. - Passive assembly

– No separate power required; integrates directly between Honeywell hardware and terminal assemblies. - Time-saving for retrofits

– You might notice that replacing like-for-like cables shortens outage windows versus field-fabricated looms. - Rugged build

– Industrial-grade insulation and strain relief for cabinet vibration and frequent maintenance handling.

Technical Specifications

| Brand / Model | HONEYWELL 05074-A-012 / 0574-A-0131 (Pre-terminated cable / adapter assembly) |

|---|---|

| HS Code | 854442 (Insulated conductors fitted with connectors) |

| Power Requirements | Passive; powered only by the connected I/O circuitry (no separate supply) |

| Operating Temperature | Typically 0 to +60 °C, non-condensing cabinet environment |

| Signal Input/Output Types | Multi-pin harness for low-voltage I/O signals; pre-defined pinout to Honeywell hardware and terminal strips |

| Communication Interfaces | Passive connector interface (factory-terminated connectors on both ends, per kit revision) |

| Installation Method | Plug-and-play inside control cabinet; route per drawing, bond shields, and secure with strain reliefs |

| Dimensions & Weight | Compact harness; lightweight (commonly under 0.5 kg, length as supplied with kit) |

Application Fields

This cable/adapter set is typically used wherever Honeywell controllers or I/O modules connect to cabinet terminations or marshalling points. Common scenarios:

- DCS panels (Experion and legacy Honeywell racks) – fast interconnects between modules and terminal assemblies.

- ESD/F&G cabinets – orderly routing of discrete and analog I/O to safety or monitoring modules.

- Brownfield upgrades – like-for-like replacement during migrations to minimize re-termination risk.

- Packaged equipment skids – standardized harnessing for repeatable FAT and field commissioning.

Advantages & Value

- Reliability – Factory-terminated connectors and strain relief reduce intermittent faults and loose terminations.

- Compatibility – Intended for Honeywell hardware; pinout consistency saves hours during panel build.

- Cost savings – Pre-made harnesses typically cut installation time and avoid rework during SAT/commissioning.

- Maintainability – Clear labeling simplifies troubleshooting and accelerates loop checks during outages.

- Spares strategy – Keeping a spare harness on the shelf often prevents extended downtime after a cable fault.

Installation & Maintenance

- Cabinet environment – Route in clean, ventilated enclosures; maintain bend radius and avoid tight cable ties that pinch shielding.

- Wiring practices – Separate low-level I/O from high-voltage conductors; bond shields at designated points to limit ground loops.

- Safety – Apply LOTO before touching field wiring; verify trip bypasses are in place per site policy if connected to shutdown circuits.

- Routine checks – Inspect connectors for latch wear, re-seat during outages, and confirm torque on any screw terminals.

- Documentation – Keep the as-built pinout drawing with the cabinet file; it appears that this prevents mispatching during fast turnarounds.

Quality & Certifications

- Compliance – Typically RoHS; used within CE-compliant cabinet assemblies (verify against your project BOM).

- Materials – Industrial-grade insulation and connectors; many harnesses use UL-recognized wiring components.

- Warranty – 365 days from delivery.

A commissioning engineer told me after a refinery turnaround, “Swapping in the Honeywell harness took minutes, and our loop checks finished a day early.” That’s the kind of practical advantage this kit is designed to deliver.

Reviews

There are no reviews yet.