Description

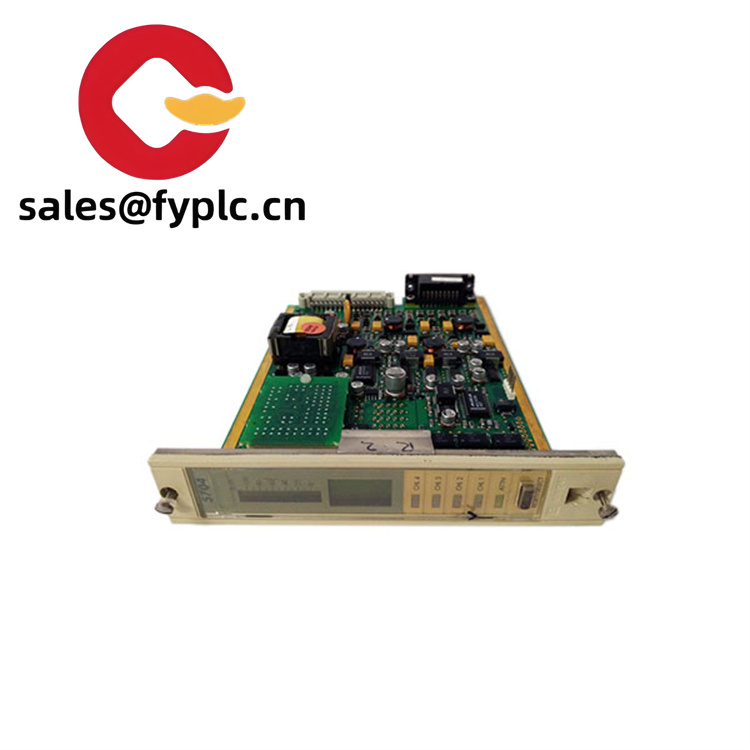

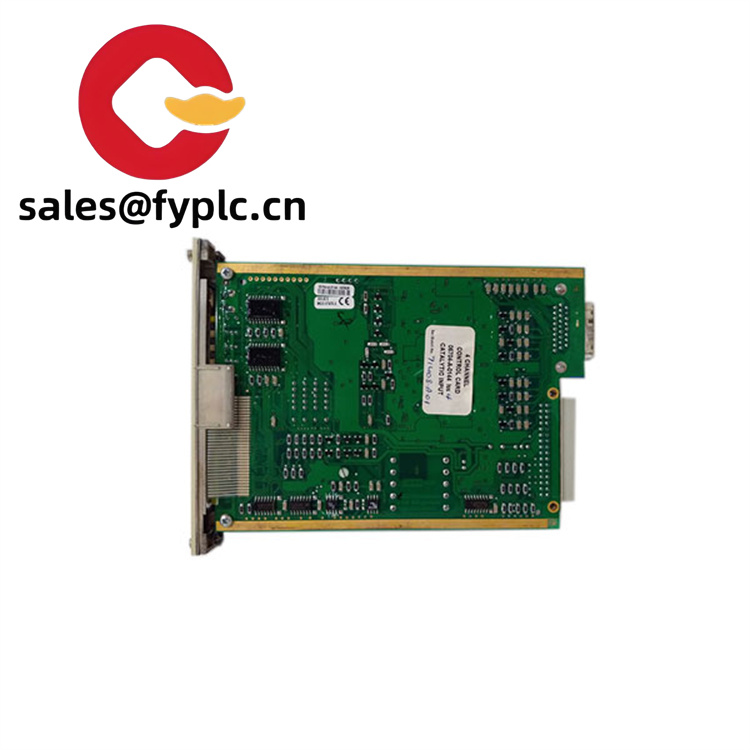

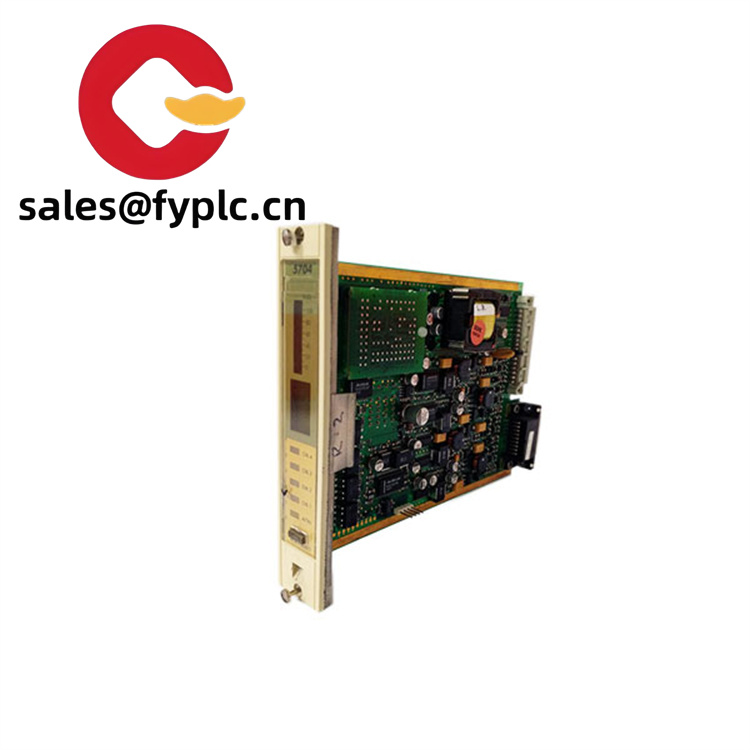

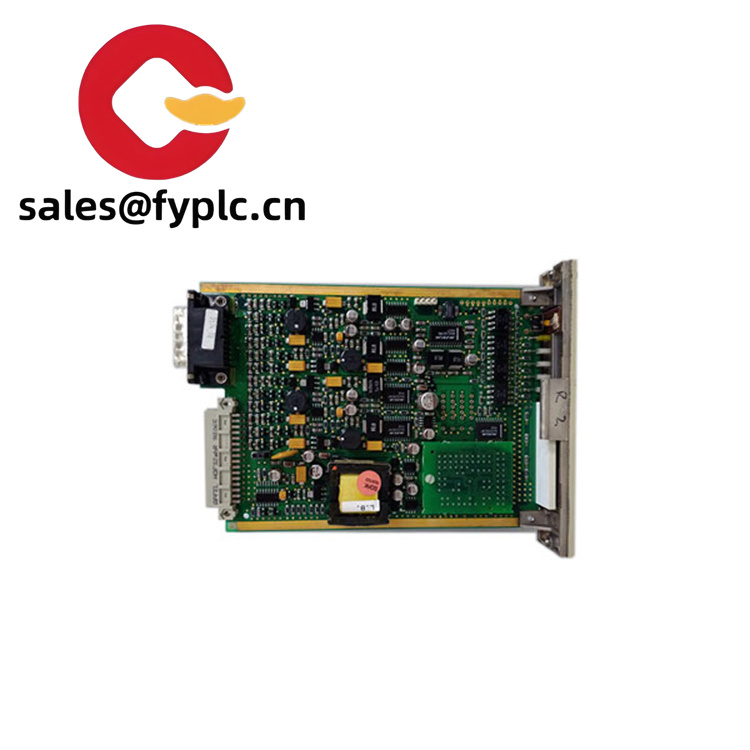

HONEYWELL 05704-A-0144 Four channel Programmable Control Card

In the chemical processing industry, where safety and precision are paramount, the PROSOFT 6104-WA-PDPM plays a vital role in connecting Profibus DP-enabled valves and pumps to a Modbus-based SCADA system. By ensuring real-time data flow between these components, it allows operators to adjust valve positions or pump speeds remotely, maintaining strict process parameters and preventing costly deviations. In both cases, the PROSOFT 6104-WA-PDPM enhances industrial automation by breaking down communication barriers, improving process visibility, and enabling more responsive control—ultimately boosting productivity and reducing operational risks.

|

Label

|

Specification

|

|

Model Number

|

05704-A-0144

|

|

Brand

|

Honeywell

|

|

Type

|

Industrial Pressure Sensor

|

|

Input Pressure Range

|

0 to 100 psi (0 to 6.89 bar)

|

|

Output Signal

|

4-20 mA analog output

|

|

Input Voltage

|

10-30 VDC

|

|

Operating Temp

|

-40°C to 85°C (-40°F to 185°F)

|

|

Accuracy

|

±0.25% full scale (BFSL)

|

|

Pressure Type

|

Gauge pressure (relative to atmospheric)

|

|

Mounting

|

Threaded process connection (1/4 NPT)

|

|

Weight

|

Approximately 0.2 kg (0.44 lbs)

|

|

Certifications

|

UL, CE, ATEX compliant for industrial use

|

|

Protection Rating

|

IP65, suitable for dusty and wet industrial environments

|

The HONEYWELL 05704-A-0144 distinguishes itself with a blend of precision and durability that sets it apart in industrial sensing applications. Its accuracy of ±0.25% full scale ensures that even small pressure variations are captured, a critical feature in processes where tight tolerances are required—such as in pharmaceutical manufacturing, where pressure fluctuations can affect product purity. This level of precision is maintained across its entire operating temperature range, from -40°C to 85°C, making it reliable in both freezing cold storage facilities and high-temperature industrial ovens.

Installing the HONEYWELL 05704-A-0144 requires careful attention to positioning and calibration to ensure accurate readings. The sensor’s 1/4 NPT threaded connection should be securely fastened to the process line, with thread sealant appropriate for the media being measured (e.g., PTFE tape for non-corrosive fluids). It’s important to mount the sensor in a location where it is not exposed to excessive vibration, as this can affect measurement stability—using a mounting bracket can help dampen vibrations in high-motion areas like near pumps or compressors. When wiring, use shielded twisted-pair cable for the 4-20 mA signal to minimize electromagnetic interference from nearby motors or drives, and ensure the power supply is within the 10-30 VDC range to avoid damage.

For more information, please click on the following link:

Reviews

There are no reviews yet.