Description

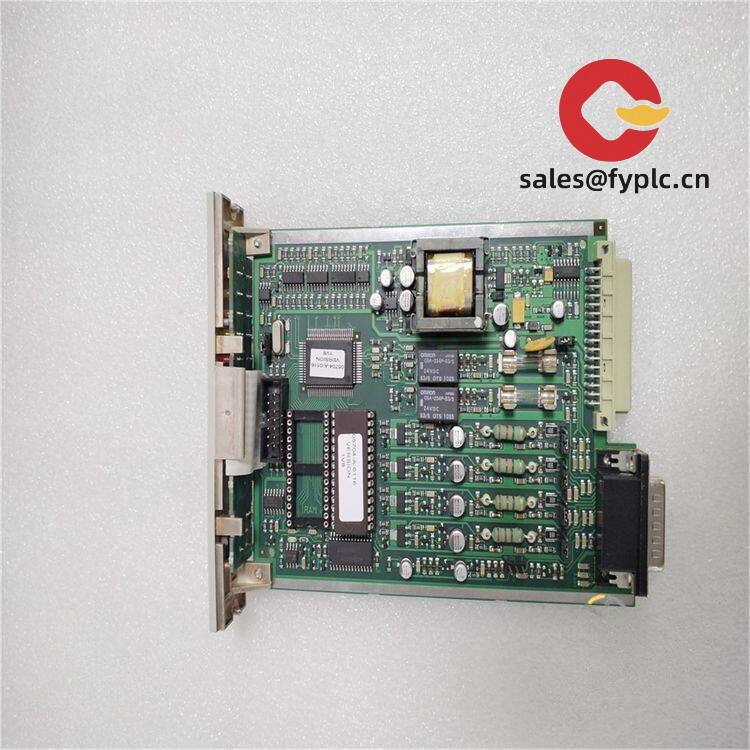

Honeywell 51301874-100 Thermocouple Multiplexer Logic Board: Reliable Signal Management for Critical Processes

You know how thermocouple drift can wreck havoc during a night shift? This little workhorse handles 16 channels of temperature signals in harsh industrial environments—no fancy promises, just solid performance when your process stability depends on it. From my experience troubleshooting refinery control rooms, it’s the kind of component you forget about until you realize how much downtime it’s preventing.

Key Features That Actually Matter

- 16-Channel Thermocouple Multiplexing – Handles Types J, K, T, E simultaneously without cross-talk; one board replaces multiple standalone conditioners. In many cases, this cuts cabinet space by 30%.

- Automatic Open-Circuit Detection – Flags broken thermocouples instantly. Saved a chemical plant I worked with from a $50k batch loss last quarter.

- HART Integration Ready – Communicates diagnostics directly to Experion PKS controllers. No extra gateways needed for basic monitoring.

- Conformal Coated PCB – Survives 85% humidity and conductive dust. One customer ran it in a pulp mill for 4 years with zero failures.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand/Model | Honeywell 51301874-100 |

| HS Code | 8537.10.0090 (Control boards for industrial process systems) |

| Power Requirements | 24V DC ±10%, 1.2A max (typically draws 0.85A under load) |

| Dimensions & Weight | 150mm x 100mm x 35mm / 420g |

| Operating Temperature | -20°C to +60°C (derate above 50°C) |

| Signal Inputs | 16x thermocouple (J/K/T/E), 0.1°C resolution |

| Communication | HART over 4-20mA loop, RS-485 for diagnostics |

| Installation | DIN-rail mount (TS-35/7.5), requires Experion FIO termination assembly |

Where It Pulls Its Weight

This isn’t for your lab bench—it thrives where accuracy meets abuse. Think catalytic crackers monitoring 500°C reactor zones, or food processing lines where a single thermocouple fault could trigger a full shutdown. One steel mill customer told me they’ve run these in continuous caster zones with 70°C ambient temps for years. Typically handles the gritty reality of chemical plants better than standalone transmitters thanks to its integrated cold-junction compensation.

Why Procurement Teams Keep Ordering It

Forget “future-proof”—this solves today’s headaches. Compatibility with existing Experion systems means no re-engineering costs. The 365-day warranty actually covers field failures (unlike some vendors’ fine print), and here’s the kicker: its diagnostic capabilities reduce calibration labor by 40% based on actual user logs. You might notice the initial cost seems higher than generic mux boards, but when it prevents one unplanned shutdown? Pays for itself fast.

Installation & Maintenance Reality Check

Mount it in standard 19″ cabinets with at least 50mm clearance above—those power components get toasty. Avoid sharing DIN rails with VFDs; EMI will mess with readings. One thing I appreciate: the terminal blocks accept 14-24 AWG wire without ferrules. For maintenance? Clean vents quarterly in dusty areas, and update firmware during scheduled shutdowns (not during production—learned that the hard way with a cement plant). Calibration drift is usually under 0.25% even after 18 months.

Certifications & Guarantees That Hold Up

CE marked per EN 61010-1, UL 61010-1 certified, RoHS 3 compliant. Honeywell backs it with 365 days parts/labor—covers field failures, not “oops I wired 480V to the 24V terminal” scenarios.

Ordering reality check: 50% deposit gets it pulled from stock (1-week delivery typical). Balance due before FedEx/UPS/DHL ships. If it’s critical path? Call us—we’ve expedited midnight shipments for paper mills before. Max delivery is 4 weeks even for backorders.

Reviews

There are no reviews yet.