Description

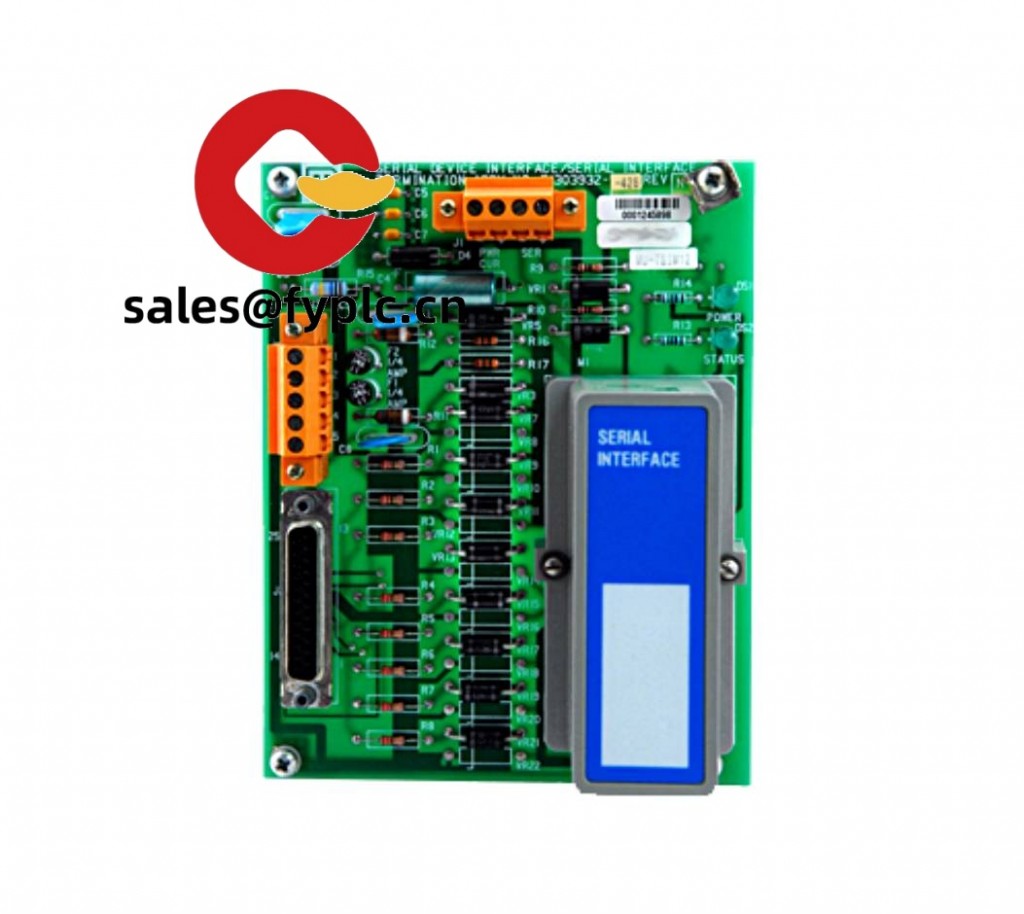

Honeywell 51304337-150 – DCS I/O Module/Termination Assembly for TDC/TPS Systems

The Honeywell 51304337-150 is a genuine Honeywell spare used in TDC 3000/Experion TPS I/O subsystems. It’s typically deployed as part of the I/O module and termination assembly chain, making it a practical drop-in replacement when you need to restore an I/O channel group without redesigning the cabinet. From my experience, this part is chosen to keep legacy cabinets running reliably while you plan migrations at your own pace.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock items; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express delivery methods: FedEx, UPS, DHL

Key Features

- Designed for Honeywell TDC 3000 / Experion TPS cabinets – Ensures mechanical and electrical compatibility with installed I/O frames in most cases.

- Backplane-integrated connection – No external power; interfaces via the system backplane/termination assembly for clean wiring.

- Service-friendly replacement – You might notice that changeover is straightforward when proper LOTO and ESD procedures are followed.

- Stable field wiring approach – Typically uses proven Honeywell termination methods, minimizing rework on existing field cables.

- Long-life build – Industrial-grade components that seem to hold up well in continuous operation environments.

- Lifecycle support – A practical option to sustain legacy loops while planning phased modernization to Experion.

Technical Specifications

| Brand / Model | Honeywell 51304337-150 |

| Product Type | DCS I/O module/termination assembly (spare), compatible with Honeywell TDC 3000/Experion TPS I/O subsystem |

| HS Code | 8537.10 (Boards/panels for electric control or distribution, for voltage ≤ 1000 V) |

| Power Requirements | No external power; supplied via system backplane/termination interface |

| Dimensions & Weight | Typical module footprint for Honeywell I/O cards; approx. 230–250 mm (L) × 90–110 mm (H) × 20–35 mm (D); ~0.3–0.5 kg |

| Operating Temperature | 0 to +50 °C (typical for cabinet-installed modules) |

| Signal Input/Output Types | Works with Honeywell I/O subsystem; actual DI/DO/AI/AO support depends on the paired IOM/FTA configuration |

| Communication Interfaces | Proprietary backplane interface; no user-facing Ethernet/serial ports |

| Installation Method | Cabinet-mounted in Honeywell I/O rack/termination assemblies; uses standard card guides and retaining hardware |

Application Fields

Plants running Honeywell TDC 3000 and Experion TPS often keep a small stock of this part to minimize downtime. Typical environments include:

- Oil & gas and petrochemical process units

- Power generation (gas, coal, and combined-cycle units)

- Chemicals, pulp & paper, water treatment

- Pharmaceutical API and batch facilities

One thing I appreciate is how it helps maintenance teams recover a faulty I/O slice quickly without re-terminating field wiring—especially during turnarounds when every hour counts.

Advantages & Value

- Reliability – OEM-grade build quality that, in many cases, matches the original installation spec.

- Compatibility – Keeps existing cabinets, channel assignments, and loop drawings intact.

- Downtime reduction – Faster swap than redesigning an I/O leg; often a same-shift replacement.

- Cost control – Extends asset life while budgeting for staged migration to newer platforms.

- Technical support – Guidance on fitment, revision alignment, and commissioning best practices.

A maintenance supervisor recently noted that replacing this part restored a batch line’s digital inputs in under two hours, saving a weekend of troubleshooting. That’s fairly typical when the failure mode is localized to a single I/O slice.

Installation & Maintenance

- Environment – Install inside a clean, ventilated control cabinet; maintain ambient 0–50 °C and avoid condensation.

- Mounting – Use the designated Honeywell rack/termination guides and secure the retaining hardware properly.

- Wiring – Verify terminal labeling and channel mapping; torque field terminations per site standards.

- ESD & Safety – Follow ESD precautions; isolate power and apply LOTO. Hot replacement is site-specific—follow Honeywell procedures.

- Routine checks – Inspect terminals for looseness or oxidation; clean dust with dry air; verify channel health in the DCS diagnostics.

- Firmware/Configuration – If paired with programmable I/O, align revisions and restore configuration from backups as required.

Quality & Certifications

- Certifications: CE compliance; commonly supplied with UL/CSA conformity in Honeywell cabinet systems

- Environmental: RoHS status typically in line with Honeywell industrial controls

- Warranty: 365-day warranty coverage

If you’d like, share your current cabinet type and I/O mix (DI/DO/AI/AO). I can double-check fitment for the 51304337-150 revision and flag any accessories you might need, such as specific FTAs, ribbon cables, or retaining hardware.

Reviews

There are no reviews yet.