Description

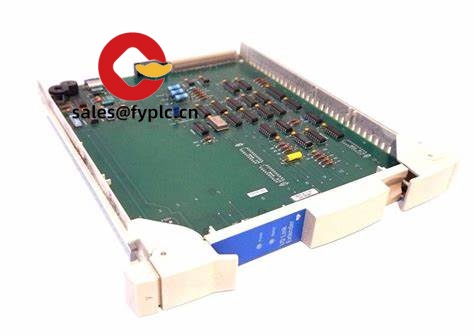

Honeywell 51304437-100 – I/O Termination Assembly for TPS/Experion Field Wiring

The Honeywell 51304437-100 is commonly used as an I/O termination assembly within Honeywell TPS/TDC 3000 and, in many cases, Experion PKS systems. From my experience, it serves as the field wiring interface between plant instruments and the controller I/O module—keeping your marshalling clean, labeled, and serviceable. You might notice that it’s a passive board, so it typically doesn’t need auxiliary power, which simplifies cabinet design and reduces points of failure.

Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Shipping: FedEx, UPS, DHL (express)

- Condition & testing: Each unit is function-checked before dispatch; traceability and photos available upon request

Key Features

- Structured field wiring: Provides a neat, labeled interface between instruments and Honeywell I/O modules, reducing wiring errors.

- Passive termination design: Typically no auxiliary power required, which helps with reliability and simplifies cabinet power planning.

- Compatible with TPS/TDC architectures: Designed to work within Honeywell’s legacy and transitional DCS environments; verify against your controller/I/O module part list for an exact match.

- Service-friendly layout: Screw-clamp terminal approach (typical) for fast loop check, re-termination, and maintenance.

- Shielding and grounding provisions: Supports proper cable shielding practices for analog and discrete signals, minimizing noise in most cases.

- Drop-in replacement path: For plants standardizing on Honeywell spares, it usually fits existing mounting backplates without cabinet rework.

Technical Specifications

| Brand / Model | Honeywell 51304437-100 |

| HS Code | 8538.90 (Parts suitable for electrical control/switchgear) |

| Power Requirements | Passive termination board; no external auxiliary power typically required |

| Operating Temperature | Typically 0 to +55°C (32 to 131°F), aligned with Honeywell cabinet environments |

| Signal Input/Output Types | Field terminations for analog and/or discrete I/O (varies by paired I/O module; confirm against your I/O listing) |

| Communication Interfaces | Internal ribbon/backplane-style connection to Honeywell I/O module; screw terminals on field side |

| Installation Method | Panel/cabinet mounting on backplate; standard industrial enclosure per Honeywell DCS practice |

| Dimensions & Weight | Standard Honeywell FTA/IOTA footprint; exact values may differ by revision—available on request |

| System Compatibility | Honeywell TPS/TDC 3000 and, in many cases, Experion PKS I/O assemblies (verify with BOM to ensure part-number match) |

Application Fields

Plants that run Honeywell DCS tend to use this board anywhere clean field terminations matter. Typical environments include oil & gas (upstream and refining), petrochemicals, power generation, specialty chemicals, pharmaceuticals, and pulp & paper. One thing I appreciate is how it helps with loop-check workflows during turnarounds—instrument techs usually get predictable terminal labeling and clear shielding points.

Advantages & Value

- Reliability: Passive construction reduces failure modes; fewer powered components to age.

- Compatibility: Designed for Honeywell DCS cabinets; works with the matching I/O module part family.

- Lower installation effort: Drop-in fit typically avoids cabinet rework and shortening outage durations.

- Lifecycle savings: Easy re-termination and fault isolation shorten maintenance windows.

- Support: We can cross-check your BOM and cabinet layouts to confirm fit and cable routing before you buy.

Feedback from a chemical plant maintenance lead: “Swap took under 20 minutes. Terminal marks matched our drawings and loop checks were straightforward.”

Installation & Maintenance

- Cabinet environment: Mount in a clean, ventilated enclosure to Honeywell DCS cabinet standards; maintain 0–55°C ambient where possible.

- Wiring practice: Use shielded twisted-pair for analog signals; terminate shields per Honeywell grounding scheme to avoid loops.

- Torque & strain relief: Tighten screw terminals to recommended torque and secure cables with tie points to prevent pull-out.

- ESD handling: Treat as an ESD-sensitive assembly; wear a wrist strap during handling and installation.

- Routine checks: Periodically re-check terminal tightness, inspect for corrosion, and verify shield continuity; clean dust with dry air.

- System alignment: When paired with controller/I/O upgrades, confirm harness/connector compatibility and module firmware (if applicable) before restart.

- Surge protection: In noisy environments, consider upstream surge suppression on field lines to extend service life.

Quality & Certifications

- Manufacturing quality: Produced under Honeywell’s quality system (ISO 9001 environment, typical for DCS hardware).

- Regulatory marks: CE and UL/CSA recognition are common for Honeywell DCS assemblies; exact markings may vary by revision—can be confirmed per lot.

- RoHS status: Varies by production date and region; we can verify based on the exact revision you require.

- Warranty support: 365-day warranty from us; new OEM units, if supplied, follow the manufacturer’s standard policy.

Next Steps

Share your cabinet photos or BOM page showing 51304437-100 and the paired I/O module number. We’ll validate compatibility, packing list, and lead time before you place the 50% advance payment. For urgent outages, we can prioritize test, documentation, and express shipping via FedEx, UPS, or DHL.

Reviews

There are no reviews yet.