Description

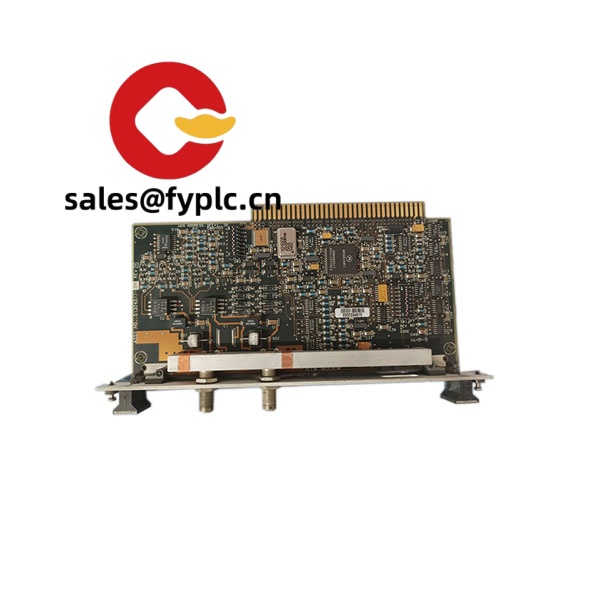

Honeywell 51304487-100 – I/O Interface/Termination Module for TDC/Experion Control Systems

The Honeywell 51304487-100 is commonly used within Honeywell TDC/TPS and Experion I/O subsystems as an interface/termination component for field signals. From my experience, plants typically deploy this part to simplify field wiring, maintain channel integrity, and enable fast, like-for-like replacement during turnarounds. You might notice that it’s designed to sit between the controller-side I/O card and your field devices, making commissioning, loop checks, and maintenance more predictable.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week for in‑stock; no more than one month at the latest

- Payment: 50% advance payment, full payment before delivery

- Shipping: FedEx, UPS, DHL express options

Key Features

- Optimized for Honeywell DCS I/O – Works within Honeywell TDC/TPS and Experion I/O architectures, helping ensure stable, predictable field connectivity.

- Clean field termination – Guides neat wiring and labeling, which typically shortens commissioning time and reduces panel rework.

- Service-friendly design – Allows fast swap-out during planned outages; technicians often appreciate the clear terminal mapping and reduced downtime.

- Robust build for cabinets – Built for industrial cabinet environments (non‑condensing), suitable for continuous operation in process plants.

- ESD-conscious layout – In many cases, the physical design and recommended handling practices help protect sensitive I/O electronics upstream.

- Backwards‑compatible use – Typically integrates with established Honeywell I/O families so you can standardize spares across similar cabinets.

Technical Specifications

| Brand / Model | Honeywell 51304487-100 |

| HS Code | 8537.10 (Boards/panels for electric control or distribution) |

| Product Role | I/O interface / termination module within Honeywell DCS I/O subsystem |

| Power Requirements | No separate external supply; mates with system I/O hardware within the cabinet |

| Signal Input/Output | Field wiring termination for the paired Honeywell I/O card (analog or discrete depending on the matched module) |

| Communication Interfaces | Not a network device; interfaces between field terminals and controller-side I/O card |

| Installation Method | Cabinet-mounted (panel/DIN-rail carrier as used in Honeywell I/O assemblies) |

| Operating Environment | Industrial control cabinet, non‑condensing; follow Honeywell cabinet and wiring practices |

Application Fields

You’ll typically see the 51304487-100 in process plants where Honeywell DCS is standard. It helps ensure tidy field terminations and stable channel performance:

- Oil & Gas (upstream wellpads, gas plants, pipelines)

- Chemicals & Petrochemicals (units with extensive analog/discrete I/O)

- Power Generation (boiler/turbine auxiliaries, BOP systems)

- Pulp & Paper, Mining & Metals, and Water/Wastewater

- Pharmaceuticals & Fine Chemicals with validated control cabinets

Feedback from a refinery maintenance lead: “We swapped this unit like-for-like during a short outage; terminal mapping was consistent, so loop checks finished earlier than planned.”

Advantages & Value

- Reliability – Durable construction for 24/7 operation in cabinet conditions; reduces nuisance wiring faults.

- Compatibility – Designed for Honeywell I/O ecosystems, which typically minimizes integration risk and engineering time.

- Lifecycle savings – Faster installation and easier replacement can cut labor hours during shutdowns.

- Technical support – Assistance with matching to the correct Honeywell I/O card and wiring standard if needed.

Installation & Maintenance

- Cabinet standards – Install in a clean, non‑condensing enclosure. Provide adequate ventilation and maintain separation from high‑voltage cabling where possible.

- Mounting – Fit to the specified Honeywell carrier or panel/DIN arrangement. Check that terminal identification aligns with the I/O card channel list.

- Wiring – Use correctly rated field cable, torque terminals per Honeywell guidance, and label conductors for traceability. Verify shield termination practice (single‑point or per site standard).

- ESD & safety – Power down affected I/O, observe ESD precautions, and isolate field circuits before handling.

- Routine care – Periodically inspect terminals for tightness, clean dust with dry air, and confirm channel integrity during scheduled loop checks. If the paired I/O card uses firmware, align revisions with site standards.

Quality & Certifications

- Manufactured to Honeywell process control quality standards; typically CE and UL/CSA compliant for panel use

- RoHS conformity where applicable

- Manufacturer’s warranty practices apply; our warranty coverage is 365 days from delivery

Supporting Components & Compatibility

If you’re pairing the 51304487-100 with a specific Honeywell I/O card, we can help confirm the exact termination style (IOTA/FTA) and any required carriers or cables. In many cases, plants standardize on matching Series C I/O modules, field termination assemblies, and associated carriers to keep spares consistent across cabinets.

- Honeywell I/O cards (analog/discrete) used in TDC/TPS/Experion systems

- Field Termination Assemblies (FTAs) and carriers for cabinet mounting

- Shield/drain management accessories and labeled terminal kits for on-site standards

Reviews

There are no reviews yet.