Description

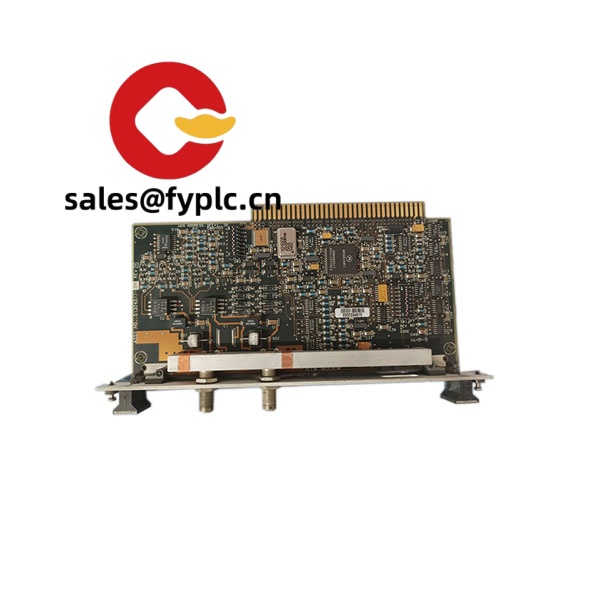

Honeywell 51304511-200 – I/O Termination Assembly (IOTA) for TPS/TDC 3000 Field Wiring

The Honeywell 51304511-200 is commonly used as an I/O Termination Assembly (IOTA) in legacy Honeywell TPS/TDC 3000 systems. From my experience, it’s the board that cleanly brings field wiring into the control system and mates with the corresponding I/O module. You might notice that these IOTAs are passive and typically sit in a protected cabinet, which means long service life with minimal upkeep. If you’re replacing aging terminations or expanding I/O in an existing TPS/TDC cabinet, this model tends to be a straightforward, like-for-like fit when matched to the correct I/O module type.

Our Order Process & Guarantees

- Warranty: 365 days

- Lead time: Typically 1 week if in stock; no more than one month at the latest

- Payment terms: 50% advance payment; full payment prior to delivery

- Shipping: Express via FedEx, UPS, or DHL

Key Features

- Purpose-built for Honeywell TPS/TDC 3000: Designed to terminate field signals and interface with the corresponding I/O module in the same I/O stack.

- Passive termination design: No separate power required; simplifies maintenance and improves reliability in most cases.

- Clear channel wiring: Screw-clamp terminal style is typical, making field terminations secure and easy to audit.

- Cabinet-friendly layout: Fits standard Honeywell I/O assemblies, helping keep your marshalling area tidy.

- Service-friendly: Quick swap-out during turnarounds; usually no firmware or configuration needed on the IOTA itself.

Technical Specifications

Application Fields

This model is typically specified in process industries running Honeywell TPS/TDC 3000 or mixed Experion TPS environments:

- Oil & Gas (refining, gas processing)

- Chemicals and petrochemicals

- Power generation and utilities

- Pulp & paper and mining

- Pharma and specialty materials where legacy DCS cabinets remain in service

Advantages & Value for Procurement

- Form/fit compatibility: In many cases a direct replacement for the existing IOTA, reducing retrofit time and risk.

- Reliable, passive hardware: No firmware and very low failure rate; fewer spares to manage.

- Short project downtime: Swap can be done during short maintenance windows; wiring labels transfer easily.

- Lifecycle support: We can help cross-check BOMs and revision levels to ensure the exact match.

A maintenance supervisor told us their cabinet rebuild “went smoother than expected” because the replacement IOTA lined up with their existing marshalling and didn’t require re-terminating shield drains—small detail, big time saver.

Installation & Maintenance

- Environment: Install inside a clean, ventilated control cabinet (IEC/UL cabinet standards), ambient typically 0–55 °C, humidity non-condensing.

- Wiring: Use correctly sized conductors; torque screw clamps per standard practice; maintain shield terminations as per site EMC policy.

- Grounding: Ensure cabinet ground and shield bars are intact to minimize noise on analog channels.

- Checks: Verify I/O module compatibility and channel mapping before commissioning; label each termination clearly.

- Upkeep: Periodic visual inspection for loosened terminals or corrosion; clean dust with dry, anti-static methods; no firmware updates needed for the IOTA.

- Safety: De-energize circuits before touching field wiring; follow lockout/tagout and site electrical standards.

Quality & Certifications

- Certifications (typical): CE and UL Recognized for associated assemblies; RoHS status may vary by revision/production year.

- Manufacturer: Honeywell process control hardware, used widely across TPS/TDC installed base.

- Warranty: 365 days replacement warranty from us.

If you can share your cabinet photos or the adjacent I/O module part number, we’ll double-check that 51304511-200 is the right IOTA variant for your channel type. One thing I appreciate is how consistent Honeywell kept these assemblies—once we confirm the pairing, installation tends to be very predictable.

Reviews

There are no reviews yet.