Description

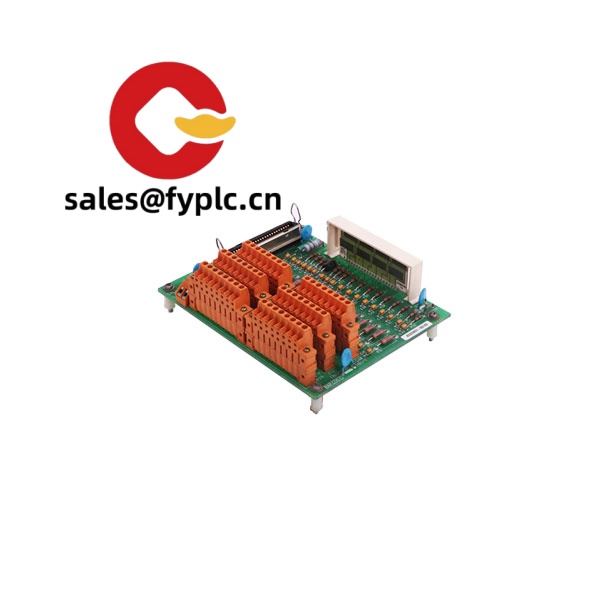

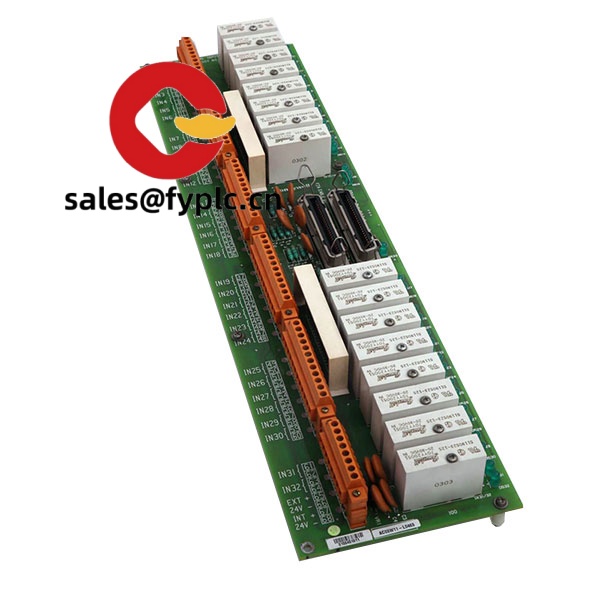

Honeywell 51304644-125 – Reliable Replacement Spare for Honeywell DCS Nodes

The Honeywell 51304644-125 is a factory-grade spare part used widely in Honeywell process control systems—typically within TDC 3000 and, in many cases, Experion PKS environments. From my experience, plants keep this on the shelf to shorten troubleshooting time and get a controller node back online without re-engineering the cabinet. You might notice that the “-125” suffix denotes a specific build or revision level, so compatibility with your installed base is usually straightforward once we cross-check your rack and node type.

Our Order Process & Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment, full balance before delivery

- Express options: FedEx, UPS, DHL

- Pre-shipment checks: Visual inspection, basic functional screening when feasible, and anti-static packaging

Key Features

- Direct fit for Honeywell systems – Designed to slide into the native Honeywell chassis, so no cabinet rework in normal cases.

- Backplane-powered module/assembly – Draws power from the system backplane; no separate power wiring required.

- Stable operation in plant environments – Built for control room conditions; typically specified to standard DCS ambient ranges.

- Revision-specific compatibility – The “-125” revision helps match existing nodes to reduce integration risk.

- Maintenance-friendly – Clear labeling and standard Honeywell retention hardware make swap-outs fast during a downtime window.

Technical Specifications

| Brand / Model | Honeywell 51304644-125 |

| HS Code | 8538.90 (Parts suitable for industrial control panels/equipment) |

| Power Requirements | Backplane powered within Honeywell system rack; no external supply |

| Operating Temperature | 0 to 55°C ambient (typical for Honeywell DCS rack modules) |

| Communication Interface | Proprietary Honeywell backplane interface; node-level integration |

| Installation Method | Slides into Honeywell chassis; secured by standard retention hardware |

Note: Exact performance details can vary slightly by revision level. We typically verify against your node type and rack PN before shipping.

Application Fields

Plants running Honeywell DCS platforms usually deploy 51304644-125 as a like-for-like replacement during maintenance windows. Typical sites include:

- Refining and petrochemicals – keeping control nodes stable during unit turnarounds.

- Power generation – fast swap to restore a controller segment during planned outages.

- Chemicals and specialty materials – lifecycle spares strategy for batch operations.

- Pharmaceuticals and food processing – minimizing batch loss through quick module replacement.

One thing I appreciate is how this part helps maintenance teams avoid re-qualification of loops or cabinet rewiring—usually it’s plug-in, verify health, and hand back to operations. A maintenance planner at a Gulf Coast refinery told me they keep two units on the shelf; having them ready cut their troubleshooting window by half last spring.

Advantages & Value for Procurement

- Compatibility certainty – We cross-check your rack/node details to confirm the -125 revision aligns with your installed base.

- Lower downtime risk – Like-for-like swap reduces commissioning and loop impact.

- Lifecycle support – Sourcing legacy Honeywell spares is getting tougher; securing proven stock avoids last-minute premium buys.

- Cost control – Refurb/new options available on request; in many cases a tested spare meets reliability goals at better cost.

- Technical support – Guidance on handling, ESD, and on-bench checks before you head to the cabinet.

Installation & Maintenance

- Cabinet environment – Install in a clean, dry control-room cabinet with adequate ventilation; avoid high vibration zones.

- Power-down practice – Unless your node explicitly supports online replacement for this position (which is uncommon), schedule a safe power-down.

- ESD handling – Use wrist straps and ESD-safe mats; keep the module in anti-static packaging until installation.

- Wiring – No external power leads; ensure proper seating into the backplane and secure with the standard retention screws/clips.

- Routine care – Periodic cabinet dusting with dry air, verify connectors are seated during outages, and keep firmware/strategy backups aligned with site change management.

- Spares strategy – It seems to be best practice to hold at least one spare per critical node type; two for units with tight uptime targets.

Quality & Certifications

- Manufactured to Honeywell’s factory standards for process control hardware.

- Typically compliant with CE/UL norms for control room equipment; RoHS status may depend on revision and manufacturing lot.

- Incoming QC and functional screening before dispatch where feasible.

- Supplier warranty: 365 days from shipment.

Related/Supporting Items

If you’re aligning spares, we can also help verify the matching node chassis/backplane, retention hardware, and compatible terminal assemblies where applicable. Share your rack PN and node type, and we’ll do a quick compatibility check so you order exactly what you need.

Send your system details (node type, rack PN, site temperature range, and any existing part labels). We’ll confirm revision compatibility for 51304644-125, propose availability (stock vs. short lead), and lock in the delivery window that fits your outage plan.

Reviews

There are no reviews yet.