Description

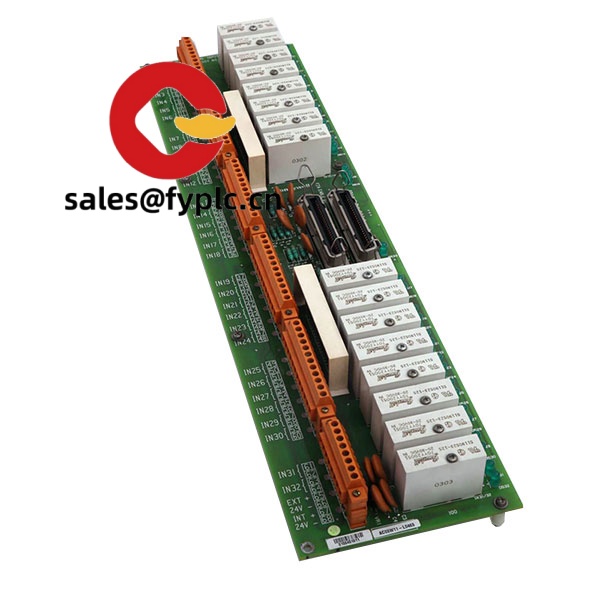

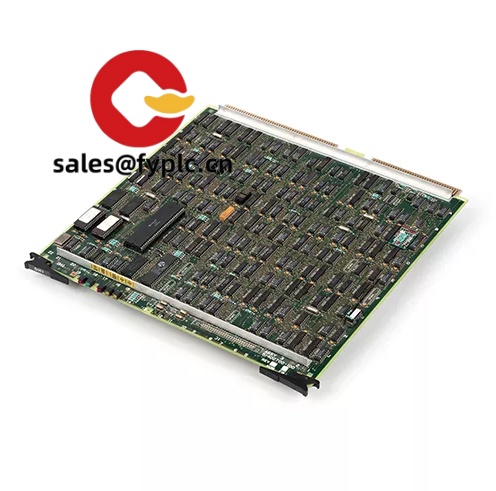

Honeywell 51304672-150 – Control System Module for TPS/TDC3000 I/O Reliability

The Honeywell 51304672-150 is a field-proven control system module used in TPS/TDC3000 (and many Experion TPS) installations to keep legacy I/O points stable and online. From my experience, teams rely on this part when they need a straight, form‑fit‑function replacement that drops into existing Honeywell cabinets without reengineering. You might notice that it’s designed to work with the standard Honeywell backplane and I/O termination assemblies (IOTA/IOM), which typically keeps loop checks short and downtime minimal.

Our Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week for in‑stock items; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

One thing I appreciate is how straightforward the swap tends to be—maintenance teams can plan a short outage, slide the module into the cardfile, run a quick functional check, and bring the unit back online. A refinery customer told me they restored a critical analog loop in under 20 minutes using a like‑for‑like 51304672-150, avoiding a long night shift.

Key Features

- TPS/TDC3000 compatibility – Designed for legacy Honeywell cabinets and cardfiles, so it typically fits without wiring changes.

- Backplane-powered module – Draws operating power from the Honeywell chassis; no external PSU or field derating needed in most cases.

- Works with IOTA/IOM – Supports standard Honeywell I/O termination assemblies, easing field cable management and loop migration.

- Industrial-grade construction – Conformal-coated PCB and robust connectors aimed at harsh sites (refining, power, chemicals).

- Service-friendly – Plug‑in replacement approach helps reduce MTTR and simplifies spare strategy for mixed-generation systems.

Technical Specifications

| Brand / Model | Honeywell 51304672-150 |

| HS Code | 8537.10 (Boards and panels for electric control, ≤1000 V) |

| Power Requirements | Supplied via Honeywell system backplane (typical logic supply 5 VDC from chassis); no external supply |

| Dimensions & Weight | Compact plug‑in PCB for TPS/TDC cardfile; typical weight ≤ 0.5 kg |

| Operating Temperature | 0 to 55 °C (typical rating for Honeywell TPS modules) |

| Signal Input/Output Types | Supports standard TPS I/O through IOTA/IOM; commonly analog (4–20 mA, 0–10 V) and discrete (dry contact / 24 VDC), depending on system configuration |

| Communication Interfaces | Honeywell backplane bus interface to the controller (e.g., UCN/HPM/C300 as applicable) |

| Installation Method | Plug‑in to Honeywell cardfile/chassis; mates with corresponding IOTA; cabinet-mounted per Honeywell TPS standards |

Note: Exact feature set and I/O point mapping can vary by site build. If you share your cabinet photo or current BOM, we can verify slotting and IOTA pairing before shipment.

Application Fields

This module is commonly deployed in:

- Oil & Gas and Refining – stabilizing legacy analog loops and discrete trips on TPS controllers

- Petrochemicals & Chemicals – maintaining batch and continuous process I/O during phased upgrades

- Power Generation – turbine and balance‑of‑plant I/O on long‑lifecycle cabinets

- Pulp & Paper, Metals, and Pharma – sustaining validated control strategies where change control is tight

Advantages & Value

- Reliability – Proven in demanding environments; conforms to Honeywell cabinet practices.

- Compatibility – Form‑fit with TPS/TDC cardfiles and IOTA/IOM, helping you avoid rewiring and requalification.

- Cost Containment – Shorter outage windows and fewer field changes typically reduce commissioning time.

- Lifecycle Support – Suits staged migrations to Experion while keeping legacy loops productive.

Installation & Maintenance

- Environment – Install in a clean, ventilated control cabinet; maintain ambient 0–55 °C; avoid condensation.

- ESD & Safety – Use ESD protection; isolate power as per site LOTO; follow Honeywell service procedures for card swap.

- Wiring – Verify IOTA/IOM type and terminal assignments; confirm shield grounding and 24 VDC polarity for discrete points.

- Commissioning – Perform slot addressing checks, loop simulation (for 4–20 mA), and point health diagnostics before handover.

- Routine Care – Inspect connectors annually, clean dust with dry air, and, where applicable, keep controller firmware aligned with site standards.

Quality & Certifications

- CE marking for EMC and safety (typical for Honeywell control modules)

- UL Recognized components (region dependent)

- RoHS compliance where applicable

- Manufactured under ISO 9001 quality systems

- Warranty coverage: 365 days

Supporting Components (for Planning)

For a smooth install, teams typically verify the matching I/O Termination Assembly (IOTA/IOM), the backplane slot assignment, and any field cabling jumpers. We can also prepare recommended spare items—connectors, termination kits, and mounting hardware—so you have everything on hand for a single maintenance window.

Reviews

There are no reviews yet.