Description

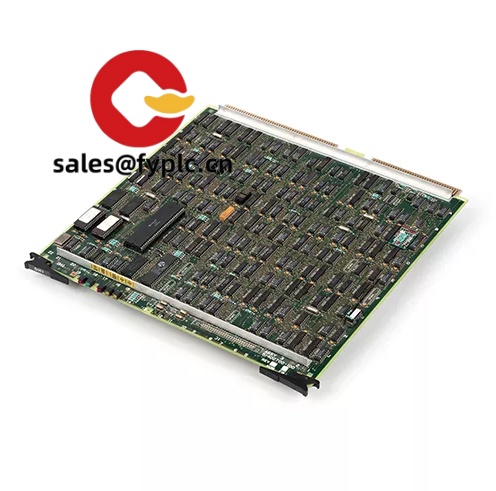

Honeywell 51400993-100 – I/O Termination Assembly for Experion/TDC I/O Wiring

The Honeywell 51400993-100 is an I/O termination/field termination assembly used in Honeywell DCS cabinets (Experion PKS / legacy TDC3000 environments) to land field wiring cleanly and connect it to the associated I/O module. From my experience, this part is typically chosen when teams want a dependable, drop-in termination board that keeps marshalling simple and minimizes rework during maintenance.

Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week for in-stock items; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- Field termination for Honeywell I/O – Provides a tidy landing point for field cables and routes signals to the selected I/O module via system cabling.

- Stable wiring under industrial loads – Screw-terminal style connections are designed to reduce loosened contacts from vibration in most cabinets.

- Fast swap and maintenance – You might notice that the board layout makes channel tracing and loop checks more straightforward during shutdowns.

- System-compatible cabling – Typically mates to Honeywell I/O through standard ribbon or system harness, helping avoid custom adapters and extra downtime.

- Cabinet-ready footprint – Fits standard Honeywell marshalling/processor cabinets; DIN-rail or panel mounting is common depending on the enclosure setup.

Technical Specifications

| Brand / Model | Honeywell 51400993-100 |

| HS Code | 8538.90 (Parts suitable for use with industrial control/switchgear of 8537) |

| Power Requirements | Passive termination board; no separate power input (draws negligible power via I/O/system interface) |

| Dimensions & Weight | Board-level footprint used in Honeywell I/O bays; typically around 250 × 100 × 30 mm; under 0.5 kg (varies slightly by production run) |

| Operating Temperature | 0 to +55 °C typical; 5–95% RH non-condensing (cabinet environment) |

| Signal Input/Output Types | Termination for DCS field signals; supports the paired module’s signal type (e.g., analog or discrete), with screw terminals for field wiring and system cable to I/O |

| Communication Interfaces | System ribbon/harness to the associated I/O module; field-side screw terminals; channel labeling for loop identification |

| Installation Method | DIN-rail or panel-mount inside DCS cabinet/marshalling panel; follow Honeywell cabinet layout and earthing practices |

Note: The 51400993-100 is part of Honeywell’s I/O termination ecosystem. Exact channel count and signal specifics depend on the paired I/O module and wiring kit; if you share your module type, we can confirm the exact fit-up.

Application Fields

- Oil & Gas and Petrochemical – Reliable field loop termination in harsh environments, especially where quick loop isolation is needed during turnarounds.

- Chemicals and Specialty Materials – Tidy wiring for mixed analog/discrete signals in batching and continuous units.

- Power Generation – Stable terminations in turbine auxiliaries, water treatment skids, and BOP systems.

- Pharmaceuticals & Food – Clean cabinet layouts that make validation and traceability easier.

- Water/Wastewater – Straightforward marshalling with low maintenance demand.

Advantages & Value

- Reliability in the cabinet – Solid terminal hardware that typically holds up well under vibration and temperature cycling.

- Compatibility with Honeywell ecosystems – Designed for Experion/TDC I/O; avoids ad-hoc adapters and undocumented wiring.

- Serviceability – Clear channel markings reduce troubleshooting time during loop checks or I/O card swaps.

- Procurement confidence – Stable part number, strong installed base, and straightforward logistics help keep project schedules predictable.

Installation & Maintenance

- Environment – Mount in a clean, ventilated cabinet; maintain clearance for wiring bend radius and label visibility.

- Grounding & shielding – Follow Honeywell grounding scheme; bond cable shields at the recommended end to reduce noise pickup.

- Wiring – Torque terminals per spec; segregate low-level analog from high-voltage conductors; use ferrules where applicable.

- Safety – De-energize loops before changes; verify isolation when working in mixed DI/DO/AI marshalling areas.

- Routine checks – Tighten terminals during scheduled outages; inspect for discoloration or loosened screws; update cabinet drawings when reallocating channels.

Quality & Certifications

- Typical compliance: CE and UL/CSA for control cabinet components (varies by build year and region).

- Manufacturing standards: Produced under Honeywell’s quality system; documentation and labeling support traceability.

- Warranty: 12 months (365 days) from delivery.

Real-world note: A maintenance lead at a Gulf Coast chemical plant told us they swapped in 51400993-100 units as part of a phased cabinet refresh. The biggest win seemed to be faster loop tracing—less time with the multimeter, more time closing out punch-list items.

If you share the exact I/O card type and cabinet layout, we can verify the specific cable set and termination style to ensure it’s a clean, same-day fit.

Reviews

There are no reviews yet.