Description

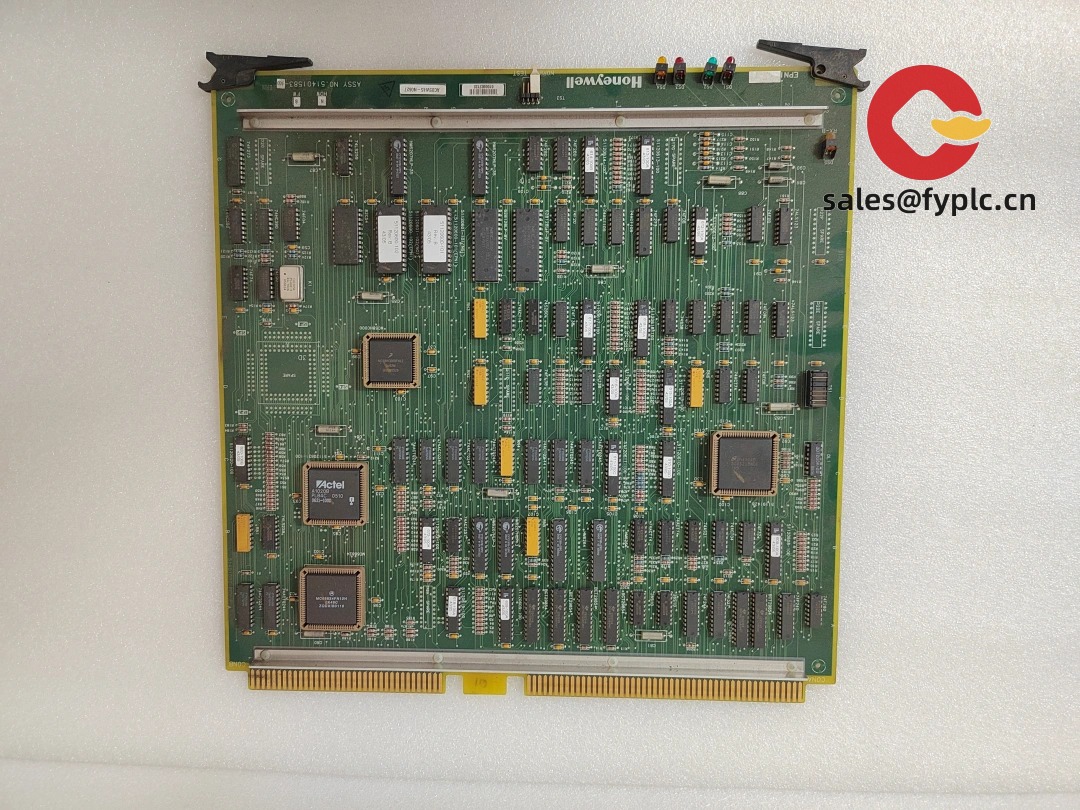

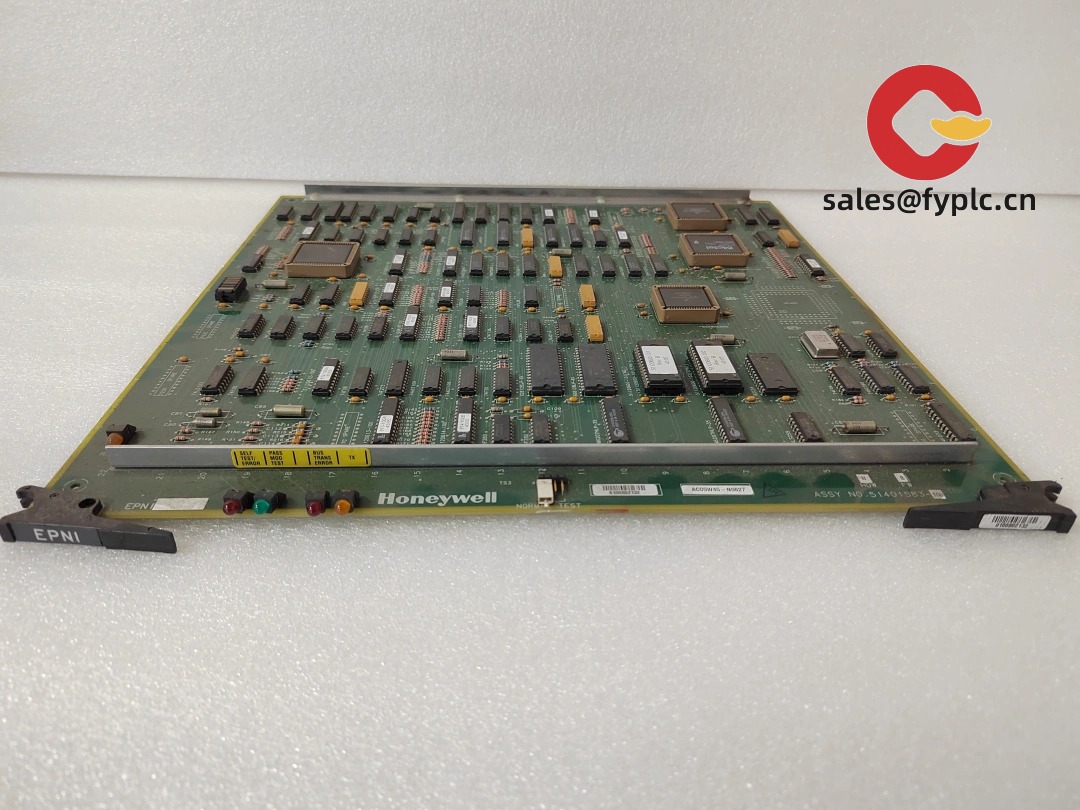

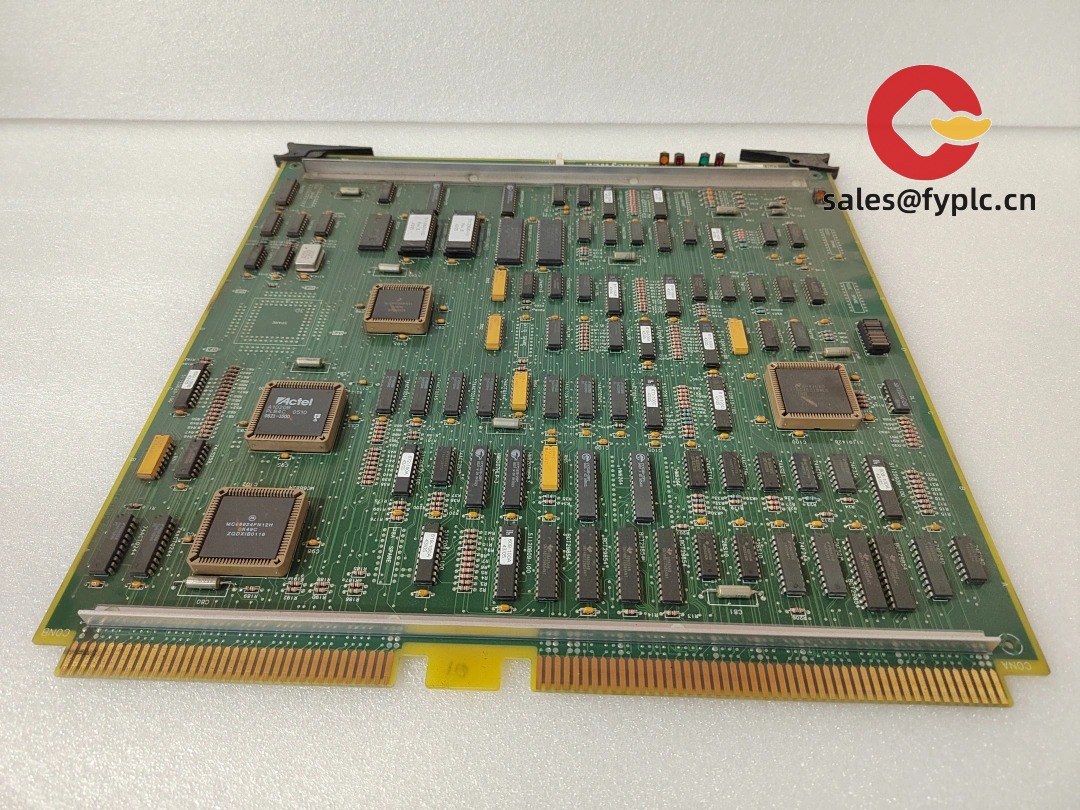

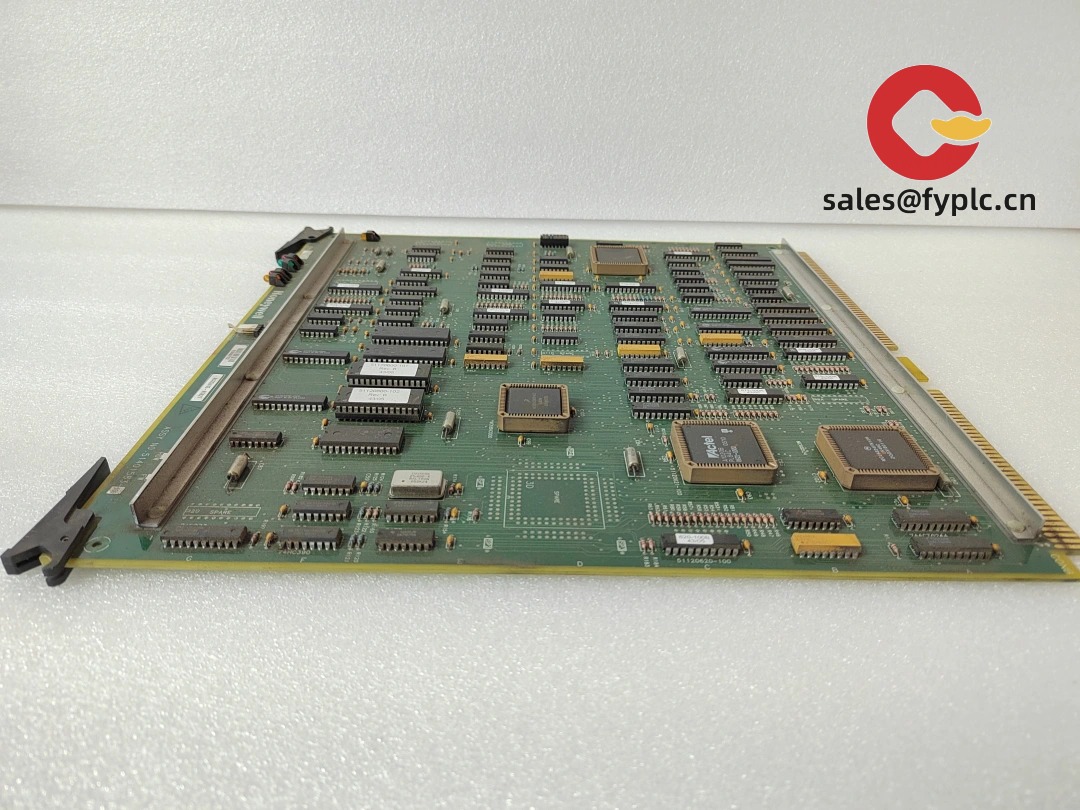

Honeywell 51401583-100 / EPNI – Enhanced Plant Network Interface for TDC/TPS Nodes

Honeywell 51401583-100, commonly known as EPNI, is the Enhanced Plant Network Interface used to bridge legacy TDC 3000 / TPS nodes onto the Plant Network (Ethernet). From my experience, it’s the straightforward way to restore or add Ethernet connectivity without reworking cabinet wiring—pull the old board, seat the EPNI, land the RJ‑45, and the node usually comes back online within minutes. You might notice that sites favor this OEM path during brownfield upgrades because it keeps the LCN/TPS side intact while modernizing the network link.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock; no more than 1 month at the latest

- Payment method: 50% advance payment; full payment for delivery

- Express delivery methods: FedEx, UPS, DHL

Key Features

- Plant Network interface – Presents node services on Ethernet for operator stations, servers, and peer communications.

- Backplane powered – Draws low‑voltage rails via the Honeywell node chassis; no separate PSU wiring.

- Drop‑in replacement – Like‑for‑like board swap typically restores connectivity without cabinet rewiring.

- Status indication – Link/activity LEDs (by revision) simplify bring‑up and quick diagnostics.

- Legacy migration friendly – Useful when modernizing networking while keeping TDC/TPS functionality stable.

Technical Specifications

Specs below reflect what’s typical for EPNI hardware. If you share your node tag and network settings, we’ll confirm revision compatibility before shipment.

| Brand / Model | Honeywell 51401583-100 / EPNI (Enhanced Plant Network Interface) |

| HS Code | 8538.90 (Parts suitable for industrial control equipment) |

| Power Requirements | Supplied via node backplane; no external power connection to the board |

| Dimensions & Weight | Plug‑in module form factor for Honeywell node chassis; approx. 0.4–0.6 kg (board mass, typical) |

| Operating Temperature | Control‑room ambient; typically 0 to +50/60 °C |

| Signal Input/Output Types | Backplane interface to node electronics; front/edge RJ‑45 Ethernet to Plant Network (rev dependent) |

| Communication Interfaces | 10/100Base‑T Ethernet for Plant Network connectivity |

| Installation Method | Front plug‑in to the Honeywell node chassis; connect RJ‑45; configure IP/link per site standard |

Application Fields

- TDC 3000 / TPS control rooms linking nodes to plant Ethernet for operator stations and servers

- Peer‑to‑peer node communications and historian access over the Plant Network

- Brownfield migrations where Experion services consume data from legacy nodes

- Spare strategies to de‑risk plant network outages on mature systems

Advantages & Value

- Low integration risk – In many cases a direct, like‑for‑like swap that preserves wiring and node setup.

- Uptime focused – Having a verified spare EPNI often turns a network fault into a same‑shift recovery.

- Compatibility – Native fit with Honeywell node backplanes and standard plant Ethernet practices.

- Lifecycle support – Traceable part numbers and a 365‑day warranty align with planned outages.

Installation & Maintenance

- ESD handling – Use a grounded wrist strap and antistatic surface when installing or removing the board.

- Networking – Assign IP/subnet per policy; verify link speed/duplex and any port security on the switch.

- Cable routing – Keep Ethernet away from high‑EMI conductors; maintain bend radius and strain relief.

- Commissioning – Check link/activity LEDs, confirm node visibility, and validate application services.

- Routine care – Inspect connectors for oxidation; document any network configuration changes in the cabinet log.

Quality & Certifications

- UL/CE conformity typical for control room modules (revision dependent)

- RoHS status varies by vintage; we can confirm against your required build

- Manufacturer’s warranty: 12 months from shipment

If you share your node type, cabinet tag, and current Plant Network settings, we’ll verify the 51401583‑100 EPNI revision match and ship on a schedule that fits your outage plan.

Reviews

There are no reviews yet.