Description

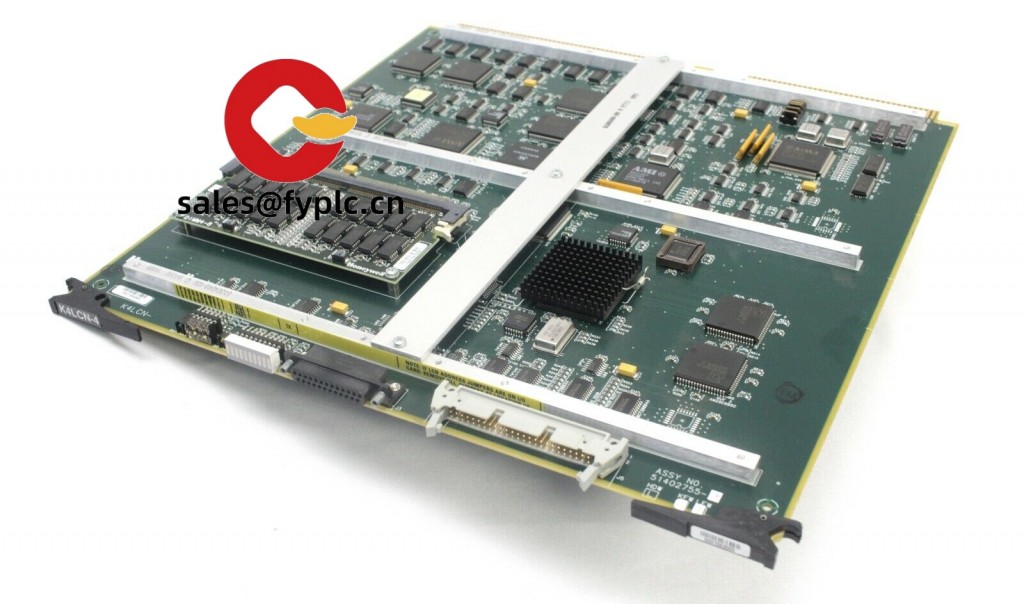

Honeywell 51402497-200 – OEM Control Module for TPS/Experion Cabinet Integration

The Honeywell 51402497-200 is an original Honeywell spare designed for cabinet-mounted process control systems in the TPS/TDC and Experion PKS families. From my experience, this part is typically used as a plug-in module within a Honeywell rack, drawing power and data via the system backplane. Teams lean on it to keep legacy and current Honeywell architectures running without forcing a wholesale migration—especially where downtime is costly and revalidation would be a headache.

You might notice that Honeywell’s 5140-series modules share consistent mechanics and handling practices: quick swap-out, keyed connectors, and tight compatibility rules across cabinet revisions. This one follows the same pattern, which in many cases makes maintenance faster and far more predictable during planned outages.

Our Order Placement Process & Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock items; no more than one month at the latest

- Payment terms: 50% advance payment; full payment before delivery

- Express delivery methods: FedEx, UPS, DHL

- Each unit is inspected, packaged with ESD protection, and shipped with traceable documentation

Key Features

- OEM Honeywell spare – Ensures native fit and behavior in TPS/TDC and Experion PKS cabinets, reducing integration risk.

- Backplane-powered design – Draws DC power from the system rack; no external supply wiring required.

- Drop-in mechanical form factor – Plug-in, keyed connectors for quick replacement during turnarounds.

- Lifecycle continuity – Helps extend installed-base life without redesigning loops or revalidating procedures.

- Service-friendly – Clear labeling and revision tracking; typically supports fast swap with minimal system disturbance.

- Quality-controlled handling – ESD-safe packaging and bench checks to minimize DOA events in the field.

Technical Specifications

| Brand / Model | Honeywell 51402497-200 |

| HS Code | 8537.10 (Boards/panels/consoles for electric control, for voltage ≤ 1,000 V) |

| Power Requirements | Supplied via Honeywell system backplane (typical low-power DC draw for rack modules) |

| Installation Method | Plug-in rack/cabinet module; keyed connectors and front retainer hardware |

| Operating Temperature | Typically 0 to +50 °C in a ventilated control cabinet (non-condensing humidity) |

| Communication Interfaces | Proprietary Honeywell system bus/backplane; cabinet-specific addressing and revision matching |

| Signal I/O Types | Module function depends on cabinet role; used within Honeywell TPS/Experion control/IO architecture |

| Dimensions & Weight | Standard Honeywell single-width card format for system racks (compact, serviceable) |

Note: Exact figures can vary by hardware revision. If you share your cabinet type and controller family, we’ll verify compatibility before shipment.

Application Fields

This module sees steady use in continuous and batch plants where Honeywell cabinets are standard: oil & gas (upstream terminals, refineries), petrochemicals, power generation, pulp & paper, specialty chemicals, metals & mining, and regulated environments like pharma/bioprocess. A maintenance lead at a Gulf Coast refinery mentioned that keeping a few 5140-series spares on the shelf cut their turnaround delays by a day—simply because swap time was minutes, not hours.

Advantages & Value

- Assured compatibility – OEM part that fits existing Honeywell racks and follows established addressing rules.

- Reduced downtime – Drop-in replacement shortens MRO windows and limits process interruptions.

- Lifecycle cost control – Extends installed asset life; avoids costly redesigns or revalidation, especially in regulated sites.

- Traceability – Serial and revision tracking simplifies documentation for audits and change control.

- Technical support – Pre-shipment checks and compatibility review help avoid fit/function surprises.

Installation & Maintenance

- Power down the affected cabinet segment per site procedures; observe lockout/tagout.

- Use ESD protection (wrist strap, ESD mat). Handle the module by edges; avoid touching pins and components.

- Verify module revision and label match your cabinet slot allocation before insertion.

- Seat the card firmly into the backplane; secure front retainers. Visually confirm no bent pins or misalignment.

- Restore power and check system diagnostics. In many cases no field calibration is needed; follow site FAT/SAT checks if required.

- Routine care: keep cabinet ventilation unobstructed; inspect connectors during outages; dust with dry, non‑abrasive methods.

- Firmware/config alignment—if applicable to your cabinet—should be coordinated under change control to avoid mismatch alarms.

Quality & Certifications

- Manufactured by Honeywell; conforms to Honeywell’s process control hardware standards.

- Typically CE/UL compliant at the system level; RoHS/ISO documentation available by hardware revision upon request.

- Each unit is inspected and function-checked before dispatch; backed by a 365-day warranty.

If you’re aligning this with a specific Honeywell cabinet (TPS/TDC or Experion PKS), share the controller family and slot detail. We’ll confirm the 51402497-200 revision fit so you get a true drop-in replacement on the first try.

Reviews

There are no reviews yet.