Description

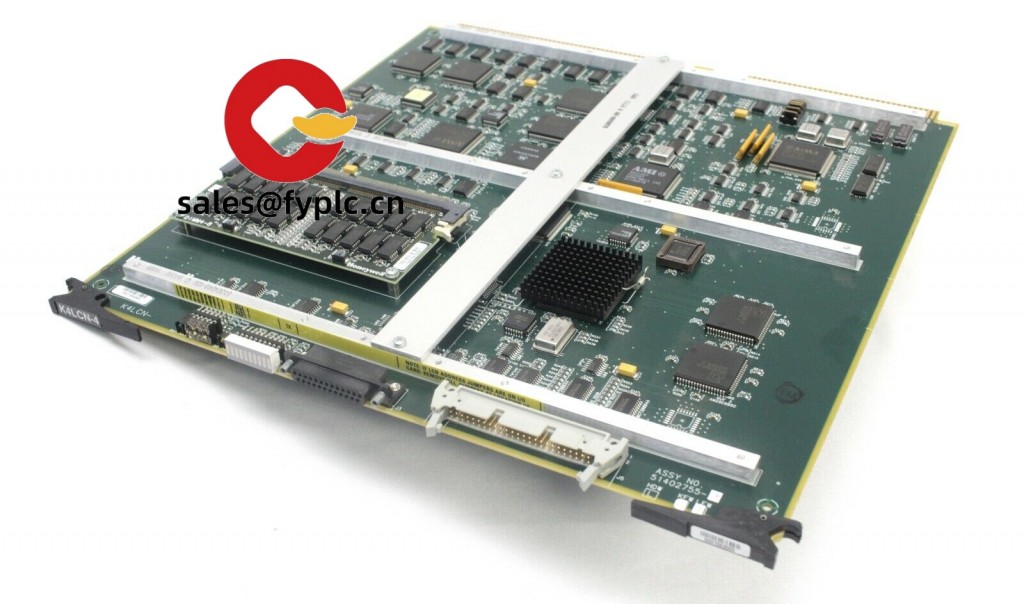

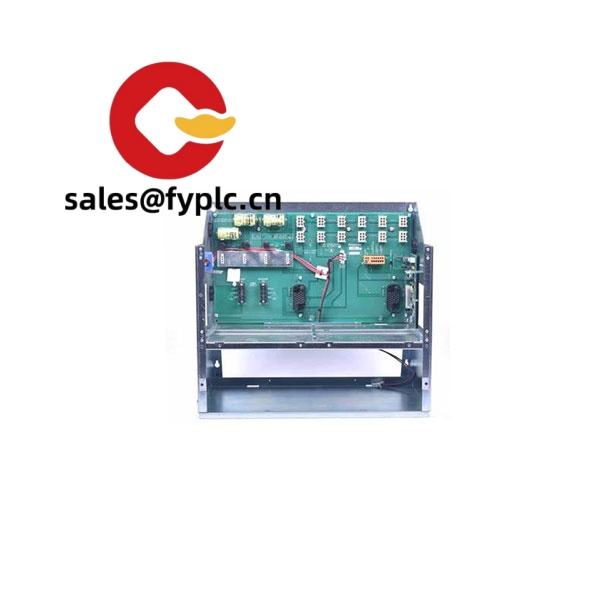

Honeywell 51403422-150 – Spare Module Assembly for TPS/Experion DCS Reliability

The Honeywell 51403422-150 is a Honeywell factory assembly part number commonly used as a plug-in module within legacy TPS/TDC 3000 and many Experion PKS cabinets. From my experience, plants typically source this unit as a like-for-like replacement to keep controller and I/O subsystems running without touching field wiring or logic. You might notice that it’s referenced in MRO lists as a “board-level spare,” which makes it a practical choice when you want to restore a node fast and avoid lengthy re-engineering.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days (replacement or repair, parts and workmanship)

- Delivery: 1 week for in‑stock items; no more than one month at the latest

- Payment: 50% advance payment, full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Drop‑in replacement – Designed to slot into the existing Honeywell rack/backplane to minimize downtime and rework.

- Backplane interface – Interfaces through the system bus; in many cases there is no direct field wiring on the board itself, simplifying swap‑outs.

- Stable operation in DCS cabinets – Typically specified for control room environments common to TPS/Experion systems.

- Lifecycle support – Suitable as an MRO spare where the installed base will remain in service for years.

- Traceable Honeywell part number – 51403422-150 helps maintenance teams align with existing BOMs and service records.

Technical Specifications

| Brand / Model | Honeywell 51403422-150 |

| HS Code | 853890 (Parts for electrical control/ distribution equipment) |

| Power Requirements | Backplane‑supplied (typical low‑voltage logic power provided by the Honeywell rack) |

| Dimensions & Weight | Compact plug‑in card form factor for Honeywell DCS card cages; lightweight module suited to standard control cabinets |

| Operating Temperature | Typically 0 to 55 °C in conditioned control room environments |

| Signal I/O Types | Backplane data/control signals; no direct field terminations on the board in most cases |

| Communication Interfaces | Proprietary Honeywell system bus via card edge/backplane connector |

| Installation Method | Tool‑less insertion into the designated Honeywell rack slot; secured by standard card retainers |

Application Fields

Plants keep 51403422-150 on hand as a maintenance spare for Honeywell control cabinets across:

- Oil & gas (refineries, pipelines, gas processing)

- Chemicals & petrochemicals

- Power generation (thermal, cogeneration, balance‑of‑plant)

- Pulp & paper, metals, and water/wastewater utilities

One thing I appreciate is how it helps maintenance teams recover a segment quickly after a board fault. A maintenance manager at a polymer plant told us they swapped this part and restored their loop execution within an hour—no field re-termination required.

Advantages & Value

- Reliability – Factory Honeywell assembly number provides the fit and stability you expect in TPS/Experion cabinets.

- Compatibility – Typically a direct match against installed BOMs; reduces risk compared to third‑party alternatives.

- Cost & downtime savings – Quick replacement can defer major migrations or redesigns.

- Support – We help verify revision compatibility and backplane slotting to avoid second trips to site.

Installation & Maintenance

- Cabinet standards – Install in a clean, ventilated control cabinet. Maintain ambient temperature within standard DCS limits (typically 0–55 °C).

- ESD & handling – Use grounding straps, antistatic mats, and avoid touching components or edge fingers.

- Wiring – This board generally relies on the backplane for power and signals; confirm slot orientation and backplane keying before insertion.

- Firmware/compatibility – Where applicable, align board revision/firmware with your system release. We can help you check controller and I/O firmware levels.

- Routine care – Periodic cabinet dust removal, connector reseat checks during shutdowns, and environmental monitoring (humidity, temperature) prolong service life.

- Safety – Isolate power to the rack per site procedures and verify that the node is safe to work on before replacement.

Quality & Certifications

- Built for Honeywell DCS environments that are CE/UL/CSA certified at the system level

- RoHS status may vary by production era; many legacy industrial controls are RoHS‑exempt under Category 9

- Backed by a 365‑day warranty

Related/Supporting Components

If you’re planning a broader maintenance window, we typically see these used together with Honeywell controller and I/O families:

- Experion C300 controllers (e.g., CC-PAON01, CC-PCNT01) – controller redundancy and processing

- Series 8/Legacy I/O modules (AI, AO, DI, DO) with corresponding IOTA/FTA terminal assemblies

- Backplane/rack assemblies and system power supplies for TPS/Experion cabinets

Reviews

There are no reviews yet.