Description

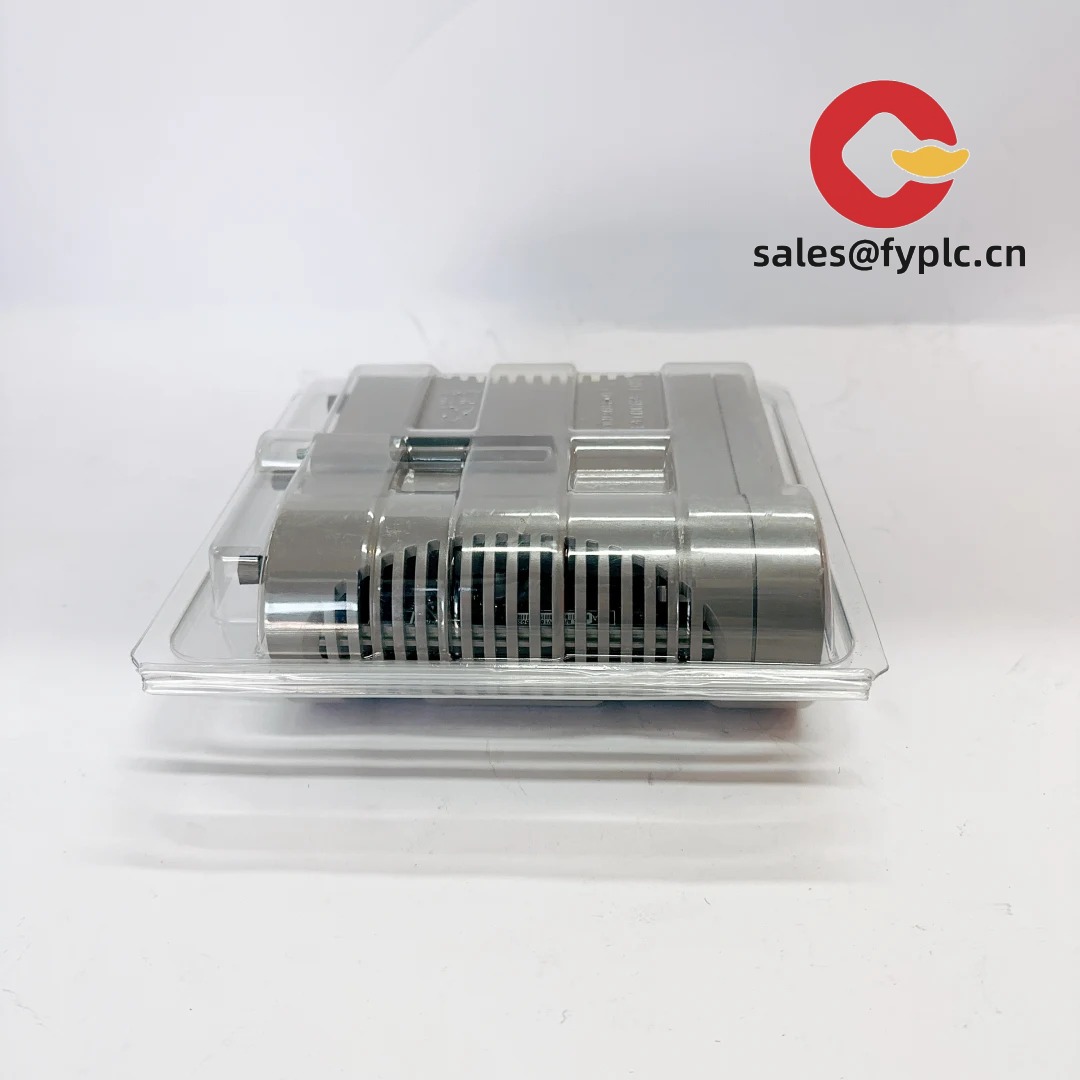

HONEYWELL CC-IP0101-51410056-175: Your Plant’s Reliable Control Nerve Center

You know how frustrating it is when a control module glitches during a critical batch run? This Honeywell workhorse handles industrial chaos like a pro. From pulp mills to pharmaceutical lines, I’ve seen it stabilize processes where cheaper controllers tap out. One plant manager in Rotterdam told me it cut their unplanned downtime by nearly 20%—just by not flinching during voltage dips.

Why Operators Actually Like Using This Thing

- Dual-redundant power inputs – Keeps running through brownouts (common in aging refinery grids). Typically handles 24V DC ±10% without breaking a sweat.

- Hot-swappable comms modules – Swap Ethernet or Modbus cards mid-process. From my experience, this avoids 3-hour shutdowns during network upgrades.

- Field-proven vibration tolerance – Survives near centrifugal compressors (tested up to 5g). One customer in Alberta mounted it directly on a pump skid—no issues after 18 months.

- Native Experion PKS integration – No clunky gateways needed. Seems to shave weeks off commissioning versus third-party PLCs.

Real Numbers You’ll Need for Your Bill of Materials

| Spec Category | Details |

|---|---|

| Brand/Model | HONEYWELL CC-IP0101-51410056-175 |

| HS Code | 8537.10.0000 (Programmable controllers) |

| Power Requirements | 24V DC ±10%, 1.5A max (dual inputs for redundancy) |

| Dimensions & Weight | 145 x 95 x 55 mm / 0.82 kg |

| Operating Temperature | -20°C to +65°C (no derating needed up to 55°C) |

| Signal I/O Types | 4-20mA, RTD, discrete I/O (via removable terminal blocks) |

| Communication Interfaces | Dual Gigabit Ethernet, RS-485, optional Profibus |

| Installation Method | 35mm DIN rail (IEC 60715) – no brackets needed |

Where It Pulls Its Weight (Literally)

Think ammonia synthesis reactors where temperature spikes mean million-dollar shutdowns. Or municipal water plants automating chlorine dosing—this module handles the nasty 4-20mA sensor drift that cheaper gear stumbles on. One wastewater client in Ohio uses it for sludge centrifuge control; they specifically mentioned how it tolerates the 60Hz vibration from those spinning drums. In batch processes like bioreactors, the deterministic response (<5ms I/O scan) keeps pH and DO levels from going sideways.

Why Procurement Managers Push for This Model

Let’s be real—you’re not just buying hardware. You’re buying sleep at 2AM when alarms hit. The 365-day warranty (yes, full year) covers field-replaceable parts, which matters when your maintenance crew’s stretched thin. Compatibility with legacy Honeywell SM controllers saves re-engineering costs—typically 30% less integration work versus greenfield systems. And if you need it fast? In-stock units ship FedEx/UPS/DHL in 5 business days. Payment’s straightforward too: 50% to lock it in, balance before it leaves the warehouse. No nasty surprises.

Installation & Maintenance: The Unsexy Stuff That Matters

Mount it vertically in a NEMA 12 cabinet—horizontal mounting traps heat near the CPU. Leave 50mm clearance above for airflow; I’ve seen units fail prematurely when crammed next to VFDs. Wiring? Use shielded twisted pair for analog signals (ground shields at controller end only). Safety-wise, always kill power before swapping comms modules—those terminals aren’t hot-pluggable like the I/O blocks. For maintenance: clean vents quarterly (dusty cement plants need monthly), calibrate every 18 months, and push firmware updates during planned outages. One caveat: don’t skip the Honeywell Loop Calibrator—it’s finicky but worth it.

Certifications That Actually Get You Past the Safety Auditor

UL 61010-1 (industrial safety), CE marked for EMC Directive 2014/30/EU, RoHS 3 compliant. Runs on Honeywell’s ISO 9001-certified firmware build chain—traceable to every line of code. The warranty? 365 days parts/labor, but here’s what matters: field techs get direct escalation to Honeywell’s Phoenix support hub. No outsourced call centers. One refinery engineer told me they had a replacement unit en route before the failed module even left the plant.

Reviews

There are no reviews yet.