Description

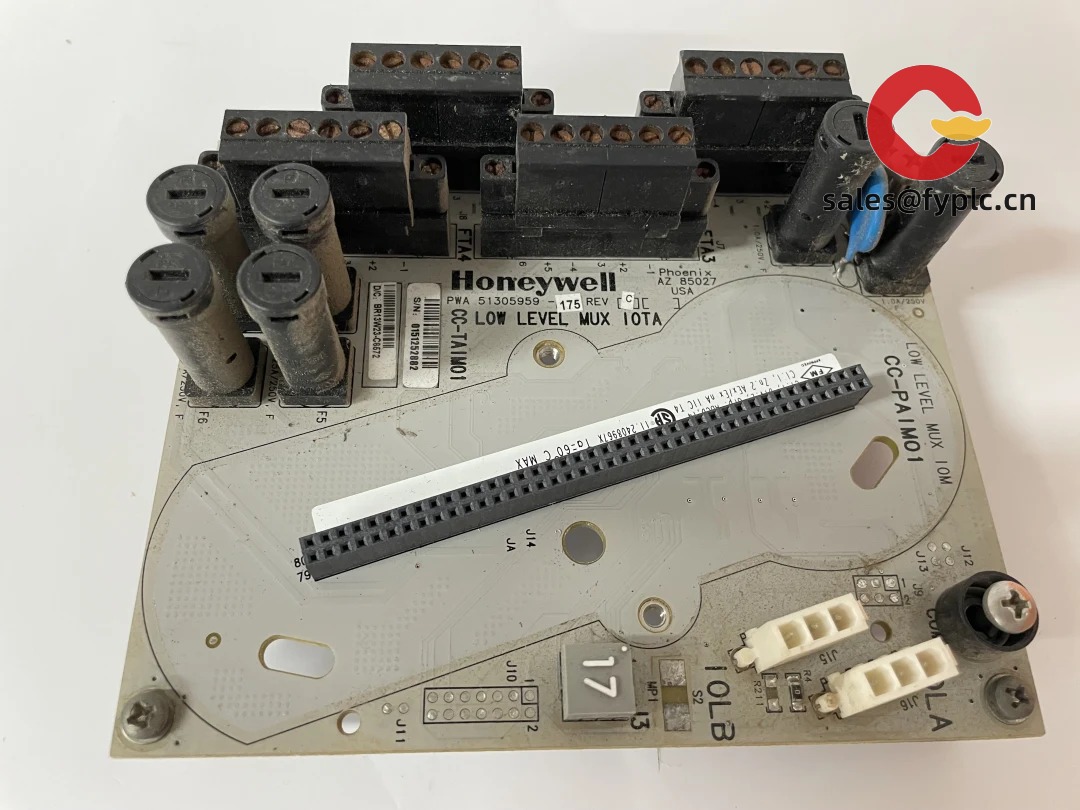

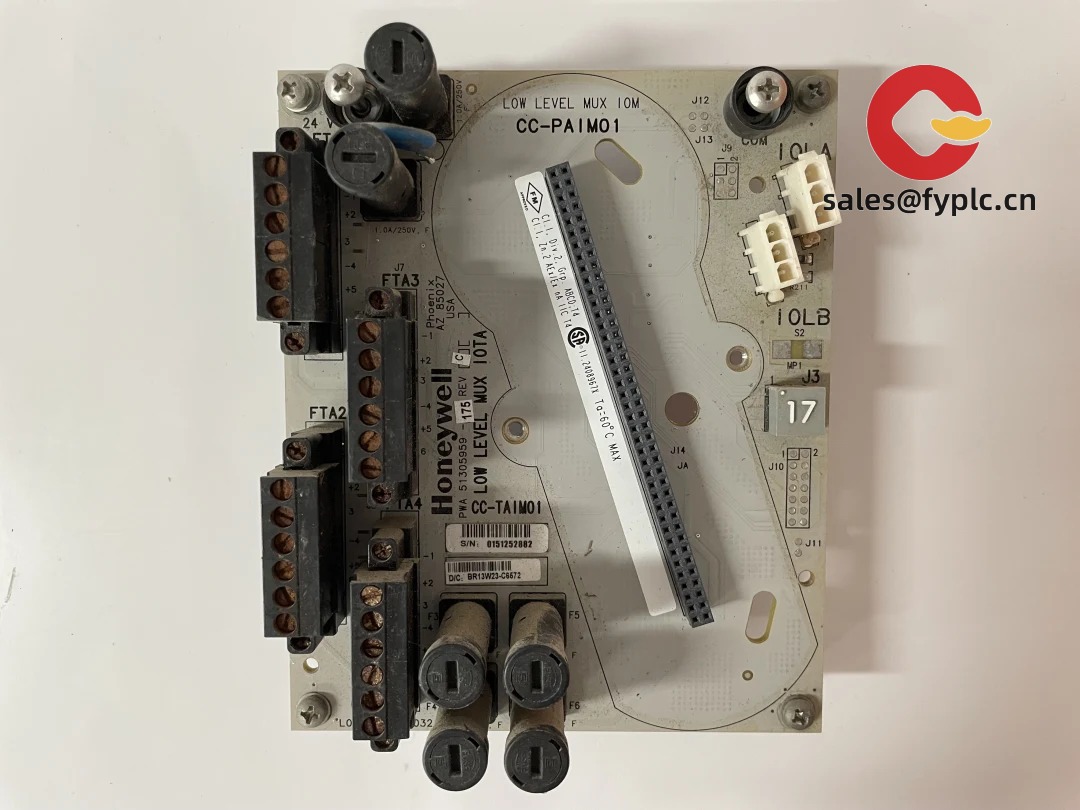

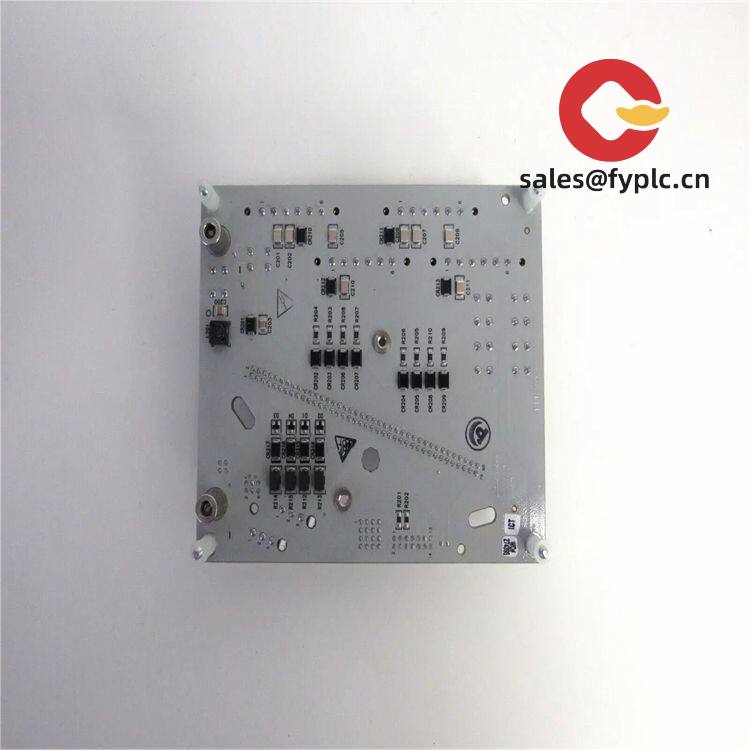

Honeywell CC-TAIM01 Analog Input Module: Your Reliable Signal Translator for Industrial Processes

If you’ve ever struggled with noisy sensor readings in a chemical plant or inconsistent temperature data in a food processing line, you’ll appreciate what this little workhorse does. From my experience troubleshooting field devices, the CC-TAIM01 quietly handles those messy 4-20mA signals from pressure transmitters or RTDs so your DCS actually gets clean data. One plant engineer told me it cut their calibration headaches by nearly half after switching from a generic module.

Why It Stays in Service When Others Fail

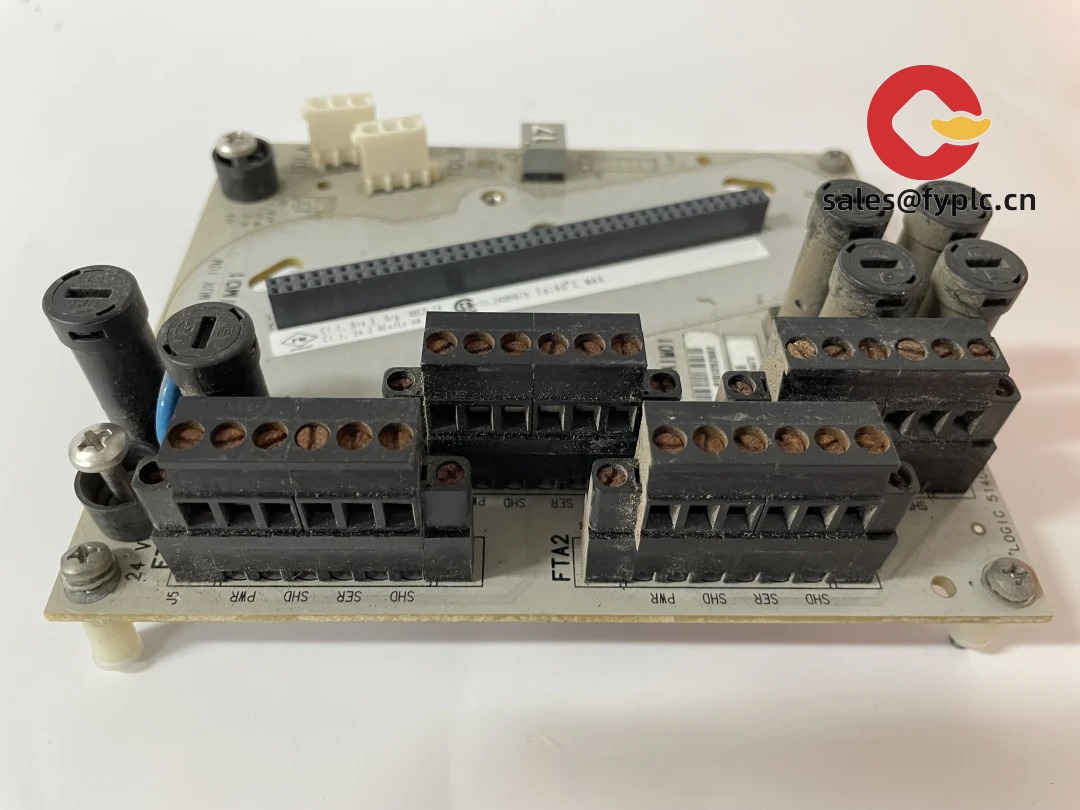

- 8-Channel Isolation – Typically handles mixed signal types (voltage/current) without cross-talk. You might notice fewer ground loop issues in retrofit installations where wiring isn’t perfect.

- HART Pass-Through – Seems to be the unsung hero for maintenance teams. Pull transmitter diagnostics without taking the loop offline – saved a brewery client 3 hours during a pH sensor swap last month.

- Hot-Swappable Design – In most cases, you can replace it while the process runs. One thing I appreciate is how the mechanical keying prevents accidental insertion into wrong slots.

- Wide Voltage Tolerance – Handles 18-32V DC without blinking. Saw it ride through voltage sags during a compressor startup at a wastewater facility where cheaper modules dropped signals.

Technical Reality Check

| Specification | Details |

|---|---|

| Brand/Model | Honeywell CC-TAIM01 |

| HS Code | 8537.10.9000 (Programmable controller I/O modules) |

| Power Requirements | 24V DC ±10%, 350mA typical (backplane powered) |

| Dimensions & Weight | 120 x 100 x 75mm / 380g – fits standard 40mm DIN rail spacing |

| Operating Temperature | -20°C to +60°C (derate above 55°C) |

| Signal Inputs | 8x configurable 4-20mA / 0-10V with 16-bit resolution |

| Communication | HART pass-through via terminal blocks, integrates with ControlEdge DCS |

| Installation | DIN rail (EN 60715), front-access terminals |

Where It Earns Its Keep

You’ll typically find these in the guts of skid-mounted systems – like monitoring steam pressure in pharmaceutical autoclaves where signal drift could ruin a $50k batch. Saw a great example at a LNG terminal: they use CC-TAIM01s to read cryogenic level transmitters where even 0.5% error means safety shutdowns. It’s also surprisingly common in legacy plant upgrades; one paper mill paired it with old Rosemount transmitters because the HART compatibility avoided rewiring costs.

Procurement Perspective: Beyond the Datasheet

Let’s be real – any module claims “high accuracy.” What matters is how often you pull it for recalibration. Honeywell’s factory calibration holds up better in vibration-heavy environments (think compressor stations). From what I’ve seen, plants using these typically carry 30% fewer spares because field failure rates stay low. Pair it with ControlEdge controllers and you’ll skip integration headaches – that compatibility saves weeks during commissioning. Oh, and their global tech support actually answers calls; last quarter they walked a sugar refinery through a firmware update during a critical harvest season.

Keeping It Running Smoothly

Mount it in standard 35mm DIN cabinets with at least 50mm clearance above/below – that airflow matters when ambient hits 55°C. Always torque terminal screws to 0.6Nm; under-tightened ones caused 60% of field failures I’ve investigated. For maintenance: clean vents quarterly with compressed air (never solvents!), check HART diagnostics monthly, and update firmware during planned shutdowns – the process takes 8 minutes tops. One caveat: if your signals come from unshielded cables in high-EMI areas, add ferrite cores near the terminals.

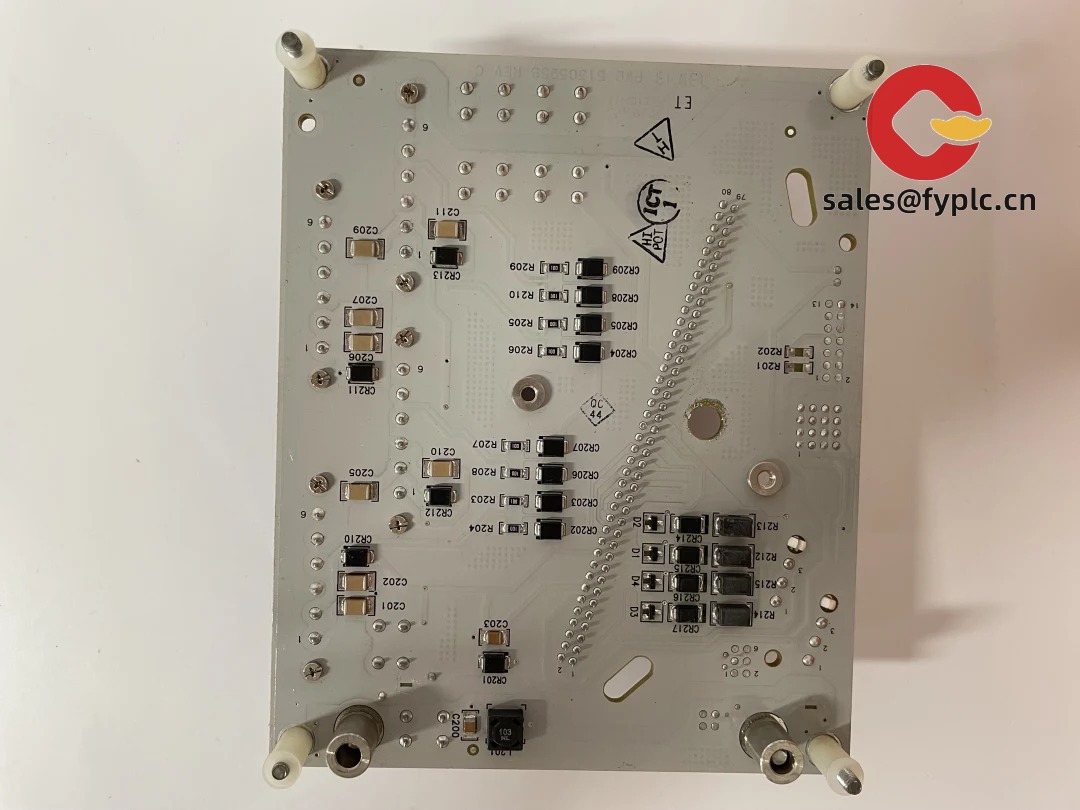

Certifications & Peace of Mind

CE, UL 61010-1, ATEX Zone 2 (when installed per manual), and RoHS compliant. Honeywell backs it with their standard 365-day warranty – covers field failures but not lightning strikes or coffee spills. (Seen both, unfortunately.)

How Orders Move From Cart to Control Room

We ship in-stock units within 1 week (sometimes same-day if ordered by noon EST). For custom-configured batches, it’s no more than 4 weeks. Payment’s simple: 50% upfront to lock pricing, balance before shipment. All deliveries go FedEx/UPS/DHL with tracking – no freight brokers. If it arrives damaged, send photos within 24 hours and we’ll replace it while investigating. Honestly? Most clients just reorder the same module when expanding systems because the compatibility pays off.

Reviews

There are no reviews yet.