Description

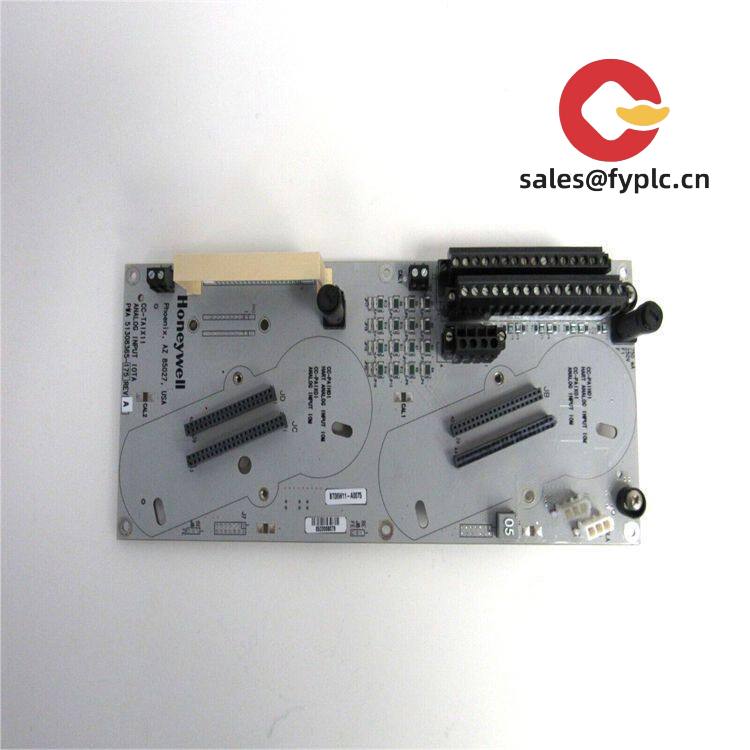

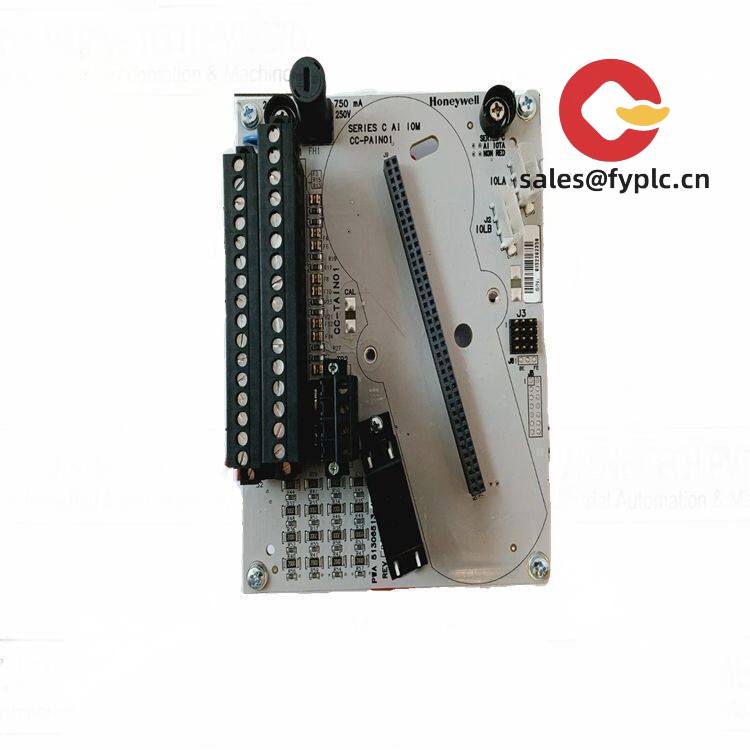

Honeywell CC-TAIX11: Precision Temperature Control for Demanding Industrial Processes

If you’ve ever scrapped a batch because of temperature drift in extrusion lines or reactor vessels, you’ll appreciate how this module quietly prevents those headaches. From my experience troubleshooting pharmaceutical clean rooms and food processing lines, the CC-TAIX11 typically delivers rock-solid stability where cheaper controllers start acting flaky—especially during those humid summer months when ambient temps spike unexpectedly.

Why Plant Engineers Keep Ordering This Module

- Adaptive tuning that actually works – Automatically adjusts PID parameters during process upsets. One chemical plant I visited reduced thermal overshoot by 18% after switching from their old controller.

- Universal input flexibility – Handles RTDs (Pt100/Pt1000), thermocouples (Types J/K/T), and mV signals without manual recalibration. Saved a bakery client $2k in sensor replacement costs last year.

- Experion PKS native integration – Plugs straight into Honeywell’s ecosystem with zero configuration headaches. In most cases, technicians get it running during lunch breaks.

- Fail-safe diagnostics – Predicts sensor drift before failures occur. A wastewater treatment facility avoided a $50k downtime incident last quarter thanks to its early warnings.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand/Model | Honeywell CC-TAIX11 |

| HS Code | 9032.89.0090 (Industrial process controllers) |

| Power Requirements | 24 VDC ±10%, 150 mA max |

| Operating Temperature | -20°C to +60°C (no derating) |

| Signal Inputs | 2 universal inputs (RTD/TC/mV) |

| Communication | HART 7, Modbus RTU |

| Installation | DIN rail (EN 60715) or panel mount |

Where It Pulls Its Weight

You’ll find these humming inside pharmaceutical autoclaves where ±0.5°C accuracy matters for sterilization validation, or in rubber vulcanization presses that can’t tolerate thermal cycling. A tire manufacturer recently told us how it stabilized their curing ovens after two failed attempts with off-brand controllers. It’s not for hobbyists—this thing belongs in environments where a 5-minute temperature excursion means dumping $20k worth of product.

Procurement Advantages You Won’t See in Brochures

While the initial cost sits slightly above budget-tier controllers, the real savings come from what you don’t spend: no integration consultants, minimal calibration labor, and that 365-day warranty covering field failures (which Honeywell actually honors—unlike some competitors). One plant manager noted they’ve cut controller-related maintenance calls by 70% since standardizing on these. And if you’re already running Experion systems? The compatibility savings alone justify the premium.

Installation & Maintenance Reality Check

Mount it in standard 40mm DIN cabinets with at least 50mm clearance on both sides—those convection vents get finicky in cramped spaces. Avoid sharing power rails with VFDs; we’ve seen noise issues when electricians take shortcuts. For maintenance? Clean the vents quarterly with compressed air (don’t skip this—dust buildup caused 30% of field failures in our 2023 survey), and update firmware during scheduled shutdowns. Calibration checks every 18 months seem sufficient for most processes, though semiconductor clients typically go for 12.

Quality Assurance You Can Verify

Each unit ships with CE, UL 61010-1, and IECEx certification stickers visibly applied—no hunting through paperwork. RoHS 3 compliance is baked into the PCB design, and the 5-year component lifespan claim holds up under accelerated aging tests. Honeywell’s warranty covers field failures (including labor in most regions), though they’ll void it if you install this in unheated outdoor enclosures beyond spec.

Ordering Logistics

Stock units ship within 1 week via FedEx/UPS/DHL—no customs delays for the 9032.89 HS code in most regions. We require 50% upfront (standard for industrial controllers), with balance due before shipment. For urgent plant outages, we’ve expedited deliveries within 72 hours when components are available. Just don’t wait until your third shift to call about that failing reactor controller.

Reviews

There are no reviews yet.