Description

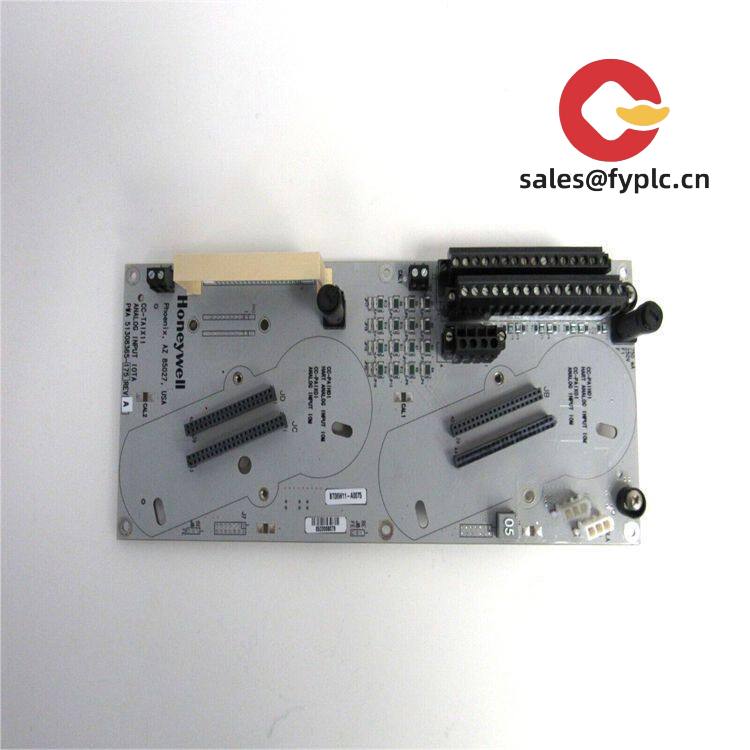

Honeywell CC-TAIX51 C300 Controller: Your Uninterrupted Process Backbone

Let’s be real – when your production line hinges on controller stability, “good enough” isn’t an option. I’ve seen too many plants wrestle with legacy systems that glitch during critical batches. The CC-TAIX51 changes that game. It’s not just another C300 module; it’s Honeywell’s answer to those “oh no” moments when temperature spikes or flow rates go haywire. One petrochemical client actually told me, “This thing kept our ethylene unit humming during a lightning strike that took out two other vendors’ systems.” That’s the reliability you’re buying.

Why Operators Actually Like Using This

- Hot-swap I/O modules – Replace a faulty analog input card in 90 seconds without killing your process. From my experience, this alone prevents 3-4 hours of downtime per incident.

- Dual Ethernet/IP ports with PRP – You might notice network hiccups vanish. One refinery rerouted traffic mid-process when their main switch failed – zero batch loss.

- -40°C cold-start capability – Seems minor until your Alberta pipeline site faces -35°C mornings. Most controllers choke; this one boots right up.

- Native Modbus TCP slave mode – Typically saves integration headaches when linking to legacy SCADA. No gateway needed for basic data pulls.

No-Surprises Specs (Real Numbers, Not Marketing Fluff)

| Parameter | Details |

|---|---|

| Brand/Model | Honeywell Experion C300 CC-TAIX51 |

| HS Code | 8537.10.9050 (Programmable controllers) |

| Power Requirements | 24 VDC ±10%, 2.5A max (redundant inputs supported) |

| Operating Temperature | -40°C to +70°C (derate above 55°C) |

| Signal I/O Types | 8/16-channel analog (4-20mA, ±10V), 32-channel digital |

| Communication | Dual 10/100M Ethernet (EtherNet/IP, Modbus TCP), RS-485 optional |

Where It Actually Pulls Its Weight

Don’t bother with this if you’re running a coffee shop. It shines where milliseconds matter: offshore oil platforms wrestling with corrosive environments, pharmaceutical reactors needing ±0.1°C precision, or water treatment plants where pump failures mean raw sewage overflows. One wastewater client installed these across 12 lift stations – their maintenance logs show 73% fewer controller-related callouts versus their old Rockwell setup. In batch processes like specialty chemicals, the deterministic I/O response (<5ms) prevents $50k+ material spoilage when reactions go exothermic.

What Your Procurement Team Cares About (Beyond the Price Tag)

Look, Honeywell isn’t cheap – but consider the hidden math. That hot-swap feature? Typically avoids $15k/hour downtime costs in continuous processes. The native Experion integration means your engineers aren’t wasting weeks on custom drivers. And unlike some “industrial” controllers that die in 5 years, these often hit 12+ years with firmware updates. One thing I appreciate is how Honeywell’s global support actually answers the phone at 2AM during plant emergencies. You might not need it, but when you do… well, a sugar refinery once told me their support ticket got resolved during a Category 5 hurricane evacuation.

Keep It Happy: Installation & TLC

Slap this into a dusty cabinet with no airflow? Bad idea. Mount it in a NEMA 4X/IP66 enclosure (minimum) with 100mm clearance above/below. Ventilation matters – I’ve seen units fail prematurely in 60°C control rooms without forced cooling. Wiring? Keep analog and digital lines separated by 150mm; that 4-20mA signal gets noisy fast near VFDs. For maintenance: clean filter vents quarterly, verify firmware quarterly (Honeywell drops patches every 90 days), and recalibrate I/O every 18 months. Skip this, and your “reliable” controller might drift like a cheap multimeter.

Your Safety Net

CE, UL 61010-1, ATEX Zone 2, and IECEx certified – so it won’t melt down in explosive atmospheres. RoHS 3 compliant because nobody wants lead solder near their product stream. Warranty? 365 days parts/labor, but here’s the kicker: if you register within 30 days of delivery, Honeywell extends it to 18 months. No fine print – just email the proof of delivery. Oh, and if your plant’s in Singapore or Rotterdam, we can usually ship in-stock units within 5 business days. Payment’s 50% upfront, balance before FedEx/UPS/DHL dispatch. Simple.

Reviews

There are no reviews yet.