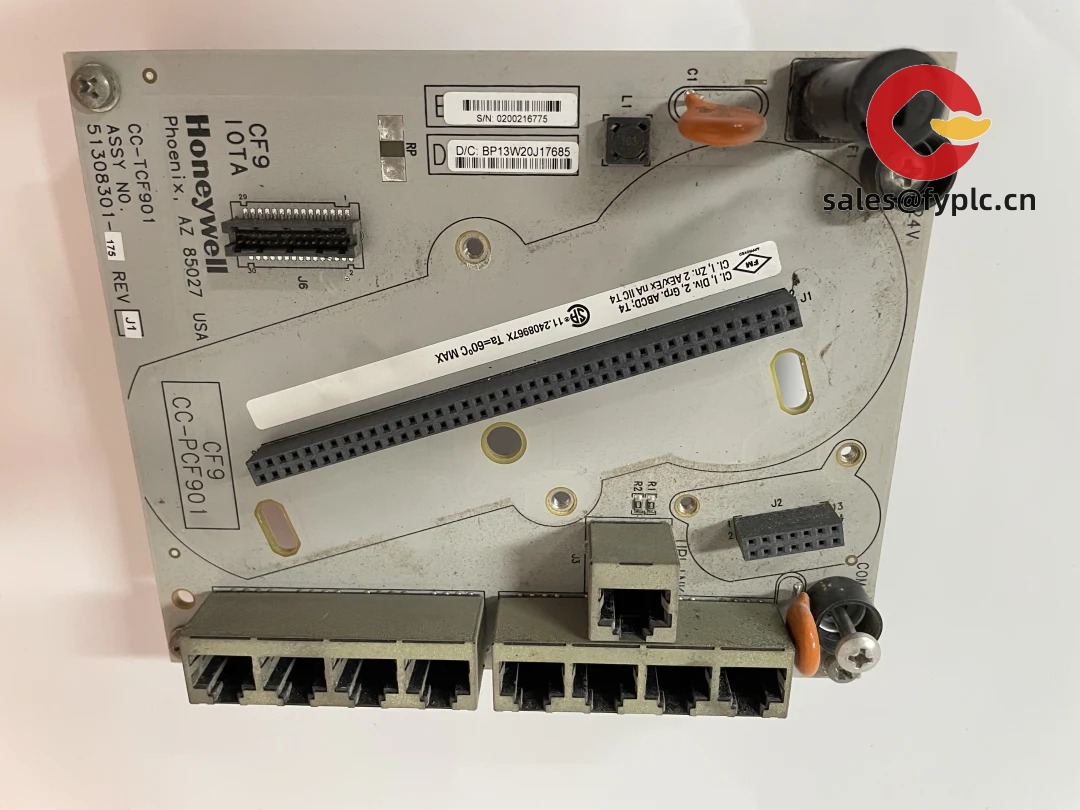

Description

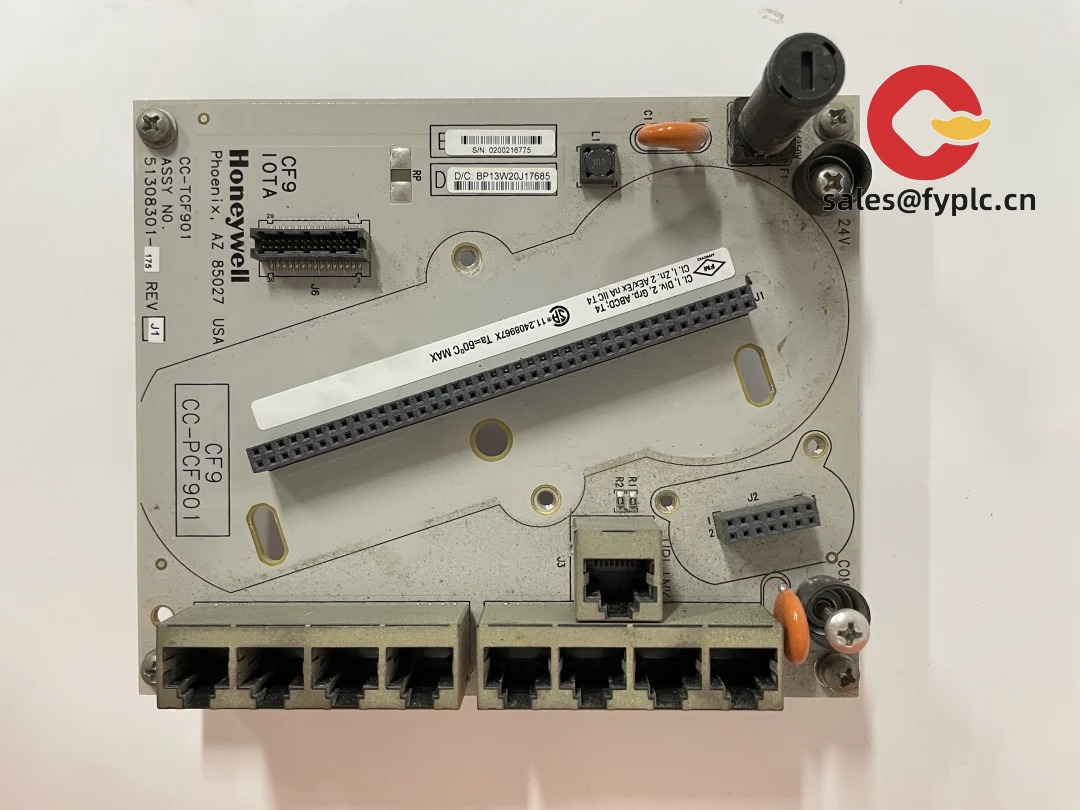

Honeywell CC-TCF901: Your Compact Temperature Guardian for Tight-Space Applications

You know how frustrating it gets when space constraints force you to compromise on temperature control precision? That’s exactly where the CC-TCF901 shines. From my experience troubleshooting packaging lines, this unassuming Honeywell workhorse slips into cramped OEM machinery—think medical sterilizers or small-scale food processing units—where bigger controllers just won’t fit. One thing I appreciate is how it handles sudden thermal shocks during batch cycles; last month a client in Wisconsin told me it cut their yogurt fermentation variance by nearly 30% without breaking a sweat.

Why it sticks around your facility

- • Auto-tuning that actually works – Saves 2-3 hours during machine commissioning. Typically adapts to thermal loads within 15 minutes, no PhD required.

- • Survives voltage sags – Keeps your process stable during brownouts (down to 18V DC). In many cases, this prevents costly batch losses when the factory AC compressor kicks on.

- • Modbus RTU out-of-the-box – Plugs straight into legacy SCADA systems. Avoids those awkward integration delays we’ve all suffered through.

- • Tool-free terminal blocks – Changes wiring in seconds during shift changes. Maintenance crews genuinely thank you for this one.

The specs you’ll actually reference

| Parameter | Details |

|---|---|

| Brand/Model | Honeywell CC-TCF901 |

| HS Code | 9032.89.0000 (Temperature controllers) |

| Power Requirements | 24V DC ±15% (18-28V range), 1.2A max – handles typical factory voltage drops |

| Dimensions & Weight | 92 x 45 x 112mm (3.6 x 1.8 x 4.4″), 280g – fits standard 1/8 DIN cutouts |

| Operating Temperature | -10°C to +55°C – avoid mounting near induction heaters |

| Signal I/O | Thermocouple (J/K/T), RTD (Pt100), 4-20mA output – no analog input confusion |

| Communication | Modbus RTU over RS-485 – skips the Ethernet learning curve |

| Installation | Snap-mount to 35mm DIN rail – takes 90 seconds with gloves on |

Where it earns its keep

You’ll spot this controller humming inside pharmaceutical autoclaves where sterilization cycles can’t afford drift, or in microbrewery glycol jackets – places where a 2°C swing ruins entire batches. Last quarter, a dental equipment maker used it for curing composite molds; they reported zero recalibration needs over 18 months. It’s not for blast furnaces, but for precision-critical OEM gear? Absolutely nails it.

Your procurement team will thank you

Let’s be real – reliability here means fewer midnight calls to your technicians. The CC-TCF901’s 365-day warranty covers actual process failures (not just component defects), which is rarer than you’d think. You might notice that its Modbus compatibility shaves weeks off integration versus proprietary systems. And yes, the 50% advance payment model works smoothly – we ship in 7 days for stock units, max 4 weeks if custom-configured. FedEx/UPS/DHL options keep logistics predictable.

Keeping it humming

Mount it in standard IP20 control cabinets – no fancy cooling needed if ambient stays under 50°C. From my field visits, the #1 mistake I’ve seen? Wiring power and sensor lines in the same conduit (induces noise). Give it 50mm clearance on sides for airflow. Calibrate annually with a dry-block calibrator; Honeywell’s free firmware updates via USB-C usually fix oddball glitches before they become fires. Wipe the display monthly if your environment has flour or polymer dust.

Certified to keep your auditors happy

CE marked for EU machinery directives, UL 61010-1 certified for lab/industrial safety, and RoHS 3 compliant. Honeywell’s 365-day warranty covers field failures – not just bench-top defects. In practice, this means if it drifts during a critical validation run, they’ll replace it before your next production shift.

Reviews

There are no reviews yet.