Description

HONEYWELL FC-BKM-0001 Battery & Key Switch Module for control and fire panel power management

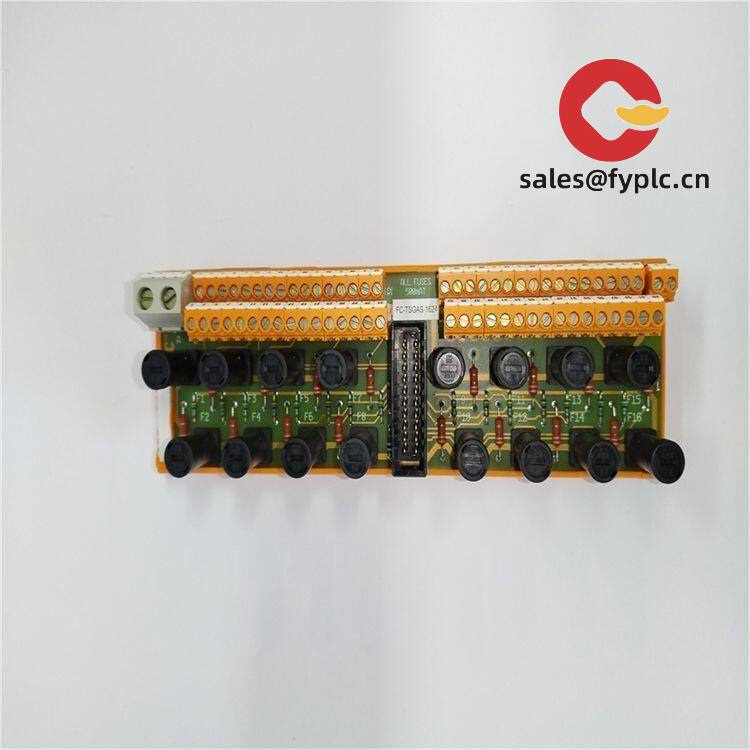

The HONEYWELL FC-BKM-0001 is a compact battery and key switch module designed to simplify standby power connection and provide a secure, keyswitch-controlled enable/disable function inside the host control panel. From my experience, this module is used where you want clean battery integration, front-panel service access, and a positive, maintained keyswitch for authorized operations—typically in fire alarm control panels, life-safety cabinets, or industrial control enclosures using 24 VDC standby supplies.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days from shipment.

- Lead time: In stock items typically ship in 1 week; no more than one month at the latest.

- Payment terms: 50% advance payment; full payment prior to delivery.

- Express options: FedEx, UPS, DHL.

Key Features

- Integrated battery interface – Provides a dedicated connection point for the panel’s standby batteries (commonly 24 VDC from two 12 V SLA in series), streamlining wiring.

- Maintained key switch – Key-operated, maintained contact for enable/disable or service mode; you might notice this reduces accidental changes by requiring a physical key.

- Status routing and safety – Arranged to support typical battery presence and isolation checks, aiding safe commissioning and maintenance.

- Panel/chassis mounting – Designed for clean installation inside Honeywell control enclosures; keeps battery terminations and the keyswitch accessible but protected.

- Service-friendly design – One thing I appreciate is the straightforward layout—techs can isolate power, change batteries, and lock out unauthorized operation quickly.

- Passive module – No on-board communication; reduces points of failure and improves long-term reliability.

Technical Specifications

| Brand / Model | HONEYWELL FC-BKM-0001 |

| HS Code | 8531.90 (Parts of electric sound/visual signaling apparatus – typical classification for fire/control panel parts) |

| Power Requirements | 24 VDC nominal from host panel; interfaces with standby battery pair (commonly 2 × 12 V sealed lead-acid in series) |

| Operating Temperature | 0 to +49°C (typical control cabinet environments; avoid condensation) |

| Signal I/O Types | Maintained key switch dry contact (e.g., SPST/DPST depending on panel wiring); battery positive/negative terminations via screw/pluggable terminals |

| Communication Interfaces | None (passive module; uses panel I/O) |

| Installation Method | Internal panel/chassis mounting within Honeywell control cabinet; secure with standoffs or designated bracket |

Application Fields

This module is typically deployed in:

- Fire alarm and life-safety panels – Stable battery interface and controlled keyswitch access for panel enable/disable.

- Industrial safety interlocks – Where a maintained key position is needed to authorize maintenance or inhibit outputs.

- Building control cabinets – Facilities that require reliable 24 VDC backup power and locked operator access, such as hospitals, airports, and data centers.

- Utilities and oil & gas – Cabinets that must remain powered during outages while restricting local operations to authorized staff.

Advantages & Value

- Reliability – Passive design reduces failure modes; from my experience, fewer electronics here often means fewer surprises in the field.

- Compatibility – Designed around Honeywell control panel practices for 24 VDC standby systems and maintained key control.

- Service time savings – Faster battery changeover and straightforward isolation help cut downtime during routine checks.

- Procurement clarity – A single, matched module for battery connection and keyswitch function avoids piecing together third-party parts.

- Support – Easier to document and maintain within a Honeywell-based panel architecture; spares stocking becomes simpler.

Installation & Maintenance

- Cabinet environment – Install in a clean, dry enclosure with adequate ventilation. Maintain ambient 0–49°C, non-condensing.

- Mounting – Use the specified backplate/bracket points. Keep battery leads short and neatly routed away from signal wiring to minimize noise.

- Wiring – Follow the panel’s polarity markings. Typical setup uses 2 × 12 V SLA batteries in series for 24 VDC; torque terminals as recommended by Honeywell.

- Safety – Isolate mains and battery before servicing. Remove battery negative first and reconnect it last. Observe ESD precautions.

- Routine maintenance – Function-test the keyswitch quarterly. Perform battery load tests semi-annually and replace batteries per site policy (often every 3–5 years). Keep terminals clean and tight.

- Firmware – Not applicable to this passive module; if the host panel firmware is updated, re-verify keyswitch logic and battery supervision.

Quality & Certifications

- Certifications – Typically supplied for use in UL and CE-marked control panel systems; RoHS compliant components are commonly used by Honeywell.

- Manufacturing – Built under ISO 9001 quality systems in most cases.

- Warranty – 12-month warranty (365 days) from shipment.

Related/Supporting Components (for planning)

- 24 VDC sealed lead-acid batteries (commonly 2 × 12 V, matched capacity as per panel load calculations)

- Battery harness/terminals and approved fusing as specified by the host Honeywell panel

- Replacement key set or keyed barrel (matching FC-BKM-0001 lock profile)

- Panel power supply/charger module compatible with the same Honeywell cabinet

Field feedback: A facilities engineer at a hospital mentioned the keyswitch feels robust and the battery terminals are easy to access, which shaved minutes off their quarterly checks—small win, but it adds up across multiple panels.

Reviews

There are no reviews yet.