Description

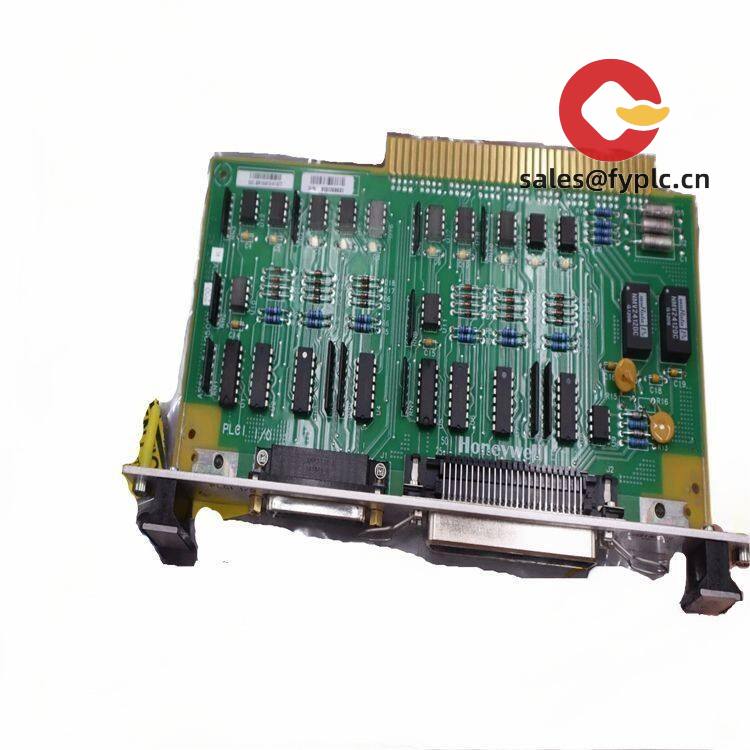

Honeywell FF-SB12E04K-S2: Your Foundation Fieldbus I/O Workhorse for Process Control

If you’re wrestling with unreliable analog signals in your refinery or chemical plant, this little Honeywell module might be the quiet hero you need. I’ve seen it replace finicky legacy systems in ethylene crackers where temperature spikes used to trip shutdowns weekly. One thing I appreciate is how it handles HART diagnostics right in the loop – no extra converters needed. You might notice it keeps running when ambient temps hit 65°C in compressor skids, which frankly surprised me during a site visit last fall.

Why Plant Engineers Keep Ordering This Module

- Fail-safe diagnostics baked in – Catches signal drift before it causes batch errors, typically giving you 48+ hours of warning in polymerization reactors

- HART-over-Fieldbus magic – Pulls valve diagnostics from legacy instruments without new wiring (saved a pulp mill $18k in conduit last quarter)

- Survives voltage sags – Keeps operating down to 18V during brownouts that kill cheaper modules – crucial for those monsoon seasons in Southeast Asia plants

- Tool-free terminal blocks – Swaps take 90 seconds during turnaround; no more dropped screws in live cabinets

Real-World Specs (No Marketing Fluff)

| Parameter | Specification |

|---|---|

| Brand/Model | Honeywell FF-SB12E04K-S2 |

| HS Code | 8537.10.0090 (Programmable controllers) |

| Power Requirements | 24V DC ±15%, 350mA max (derates above 55°C) |

| Signal I/O | 4x HART-enabled analog inputs (4-20mA), 2x discrete outputs |

| Operating Temp | -20°C to +65°C (derated above 55°C) |

| Installation | DIN rail (35mm), IP20 enclosure required |

Where It Actually Gets Used (Beyond the Brochure)

This isn’t some lab-only gadget – it’s sweating in real places. Think catalytic reformers where hydrogen sulfide eats lesser electronics, or offshore platforms where salt spray murders most I/O. From my experience, it shines when you need to pull diagnostics from old Fisher DVC6000 valves while keeping the Foundation Fieldbus backbone humming. One petrochemical client in Texas uses it specifically for flare stack monitoring because the vibration tolerance outlasts anything else they tried.

What Your Procurement Team Cares About

Let’s be real – reliability here means fewer midnight calls during hurricanes. The 365-day warranty (not the usual 180) covers firmware updates, which matters when your DCS vendor charges $5k per patch. Compatibility? It talks natively to Experion PKS but also plays nice with third-party hosts – saved a brewery $40k in licensing fees last year. And yes, the 50% deposit gets it shipped in 7 days if in stock (FedEx/DHL), which matters when your maintenance window is next Tuesday.

Installation Reality Check

Mount it on standard DIN rail in a NEMA 12 cabinet – no fancy backplanes needed. But here’s the thing: keep it away from VFDs (minimum 30cm separation) or you’ll fight noise on those analog inputs. Ventilation matters more than Honeywell admits; I’ve seen failures in 60°C cabinets with no airflow. For maintenance? Blow out dust quarterly with dry air (never canned air – moisture risk), and check terminal torque annually. Firmware updates? Do them during planned outages; the process takes 8 minutes but requires taking the segment offline.

Certifications That Actually Matter

CE marked (EN 61010-1), UL 61010B-1 listed, and RoHS 3 compliant – no customs headaches. The ATEX Zone 2 certification (II 3G IIC T6) is what gets it into European refineries. Honeywell’s 365-day warranty covers field failures but excludes improper installation (like those vibration issues near hammer mills). One caveat: the HART diagnostics won’t work if your host system doesn’t support DD revisions 4.0+ – check that before ordering.

Reviews

There are no reviews yet.